GaN-based green light LED structure with p type buffering layer and growing method of GaN-based green light LED structure

A buffer layer and p-type technology, applied in the field of optoelectronics, can solve the problems of poor antistatic ability and damage, and achieve the effects of reducing breakdown rate, improving luminous efficiency, and realizing temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

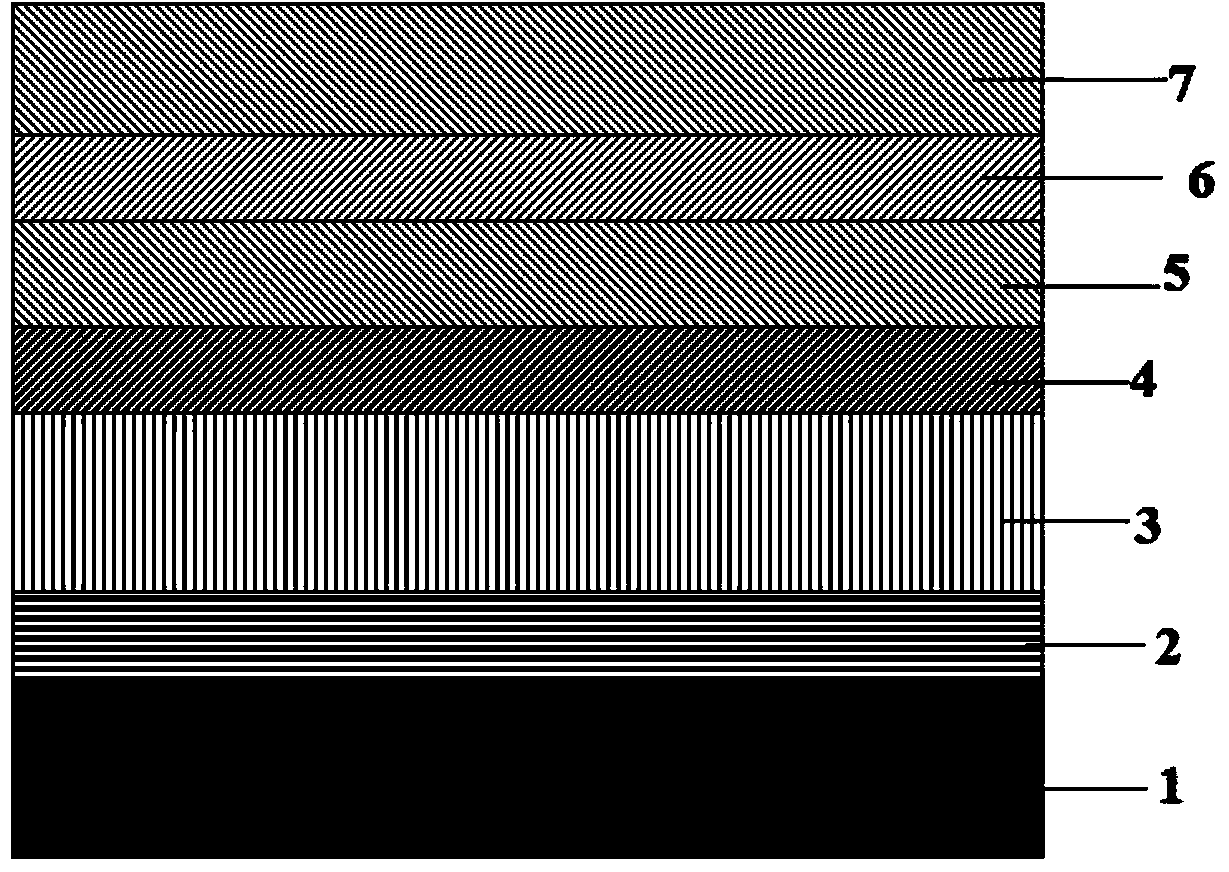

[0012] Such as figure 1 As shown, a GaN-based LED green light structure with a p-type buffer layer, a GaN nucleation layer 2, an undoped GaN layer 3, an n-type GaN layer 4, and a low-temperature In x Ga 1-x N / GaN multi-quantum well layer 5 , p-type buffer layer 6 , and high-temperature p-type GaN layer 7 .

[0013] A GaN-based LED green light structure with a p-type buffer layer, which sequentially includes a sapphire substrate layer 1, a GaN nucleation layer 2, an undoped GaN layer 3, an n-type GaN layer 4, and a low-temperature In x Ga 1-x N / GaN multi-quantum well layer 5 and high-temperature p-type GaN layer 6 are characterized by low-temperature In x Ga 1-x A p-type buffer layer 6 is grown between the N / GaN multi-quantum well layer 5 and the high-temperature p-type GaN layer 7 .

[0014] The p-type buffer layer 6 is composed of multiple layers of p-type In with different In compositions. y Ga 1-y Composed of thin N layers, the multilayer In y Ga 1-y N thin layers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com