Miniature fiber-coupled optoelectronic device and its assembly method

A technology of optical fiber coupling and optoelectronic devices, which is applied in the field of miniature optical fiber coupled optoelectronic devices and their installation and adjustment, can solve the problems of difficult fixing of optical fiber components, lack of angle adjustment, etc. Adjust the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

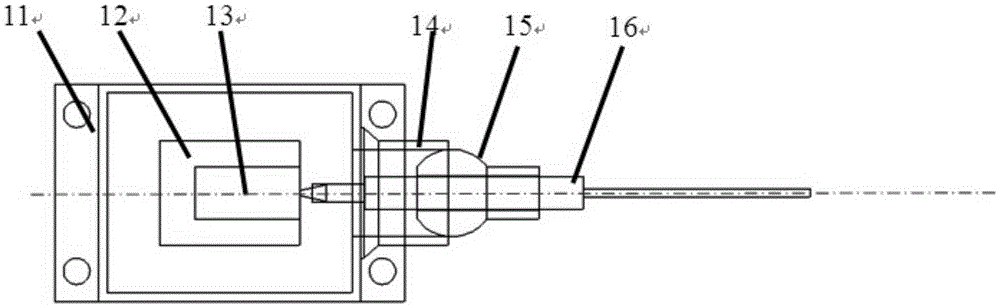

[0025] see first figure 1 , figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention; the miniature fiber-coupled optoelectronic device in this embodiment includes a shell and a cover plate 11, a heat sink 12, a light-emitting chip 13, a housing connector 14, a spherical adjustment member 15, and a metal optical fiber assembly 16. First, the light-emitting chip 13 is welded to the upper surface of the heat sink 12 with high-temperature solder such as gold tin, and then the bottom surface of the heat sink 13 and the inner bottom surface of the tube shell 11 are welded with low-temperature solder such as lead-tin; the metal optical fiber assembly 16 It is a component assembled by welding and assembling the optical fiber after metallization. The end face of the optical fiber is a flat end and coated with an anti-reflection fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com