Eccentric pump with clean-out assembly

A technology for centrifugal pumps and components, applied in the field of removing components of self-priming pumps, can solve the problems of increased cost, time-consuming, difficulty in adjusting wear-resistant plates, etc., and achieves simplified structure, simplified axial adjustment, and reduced production costs and operating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

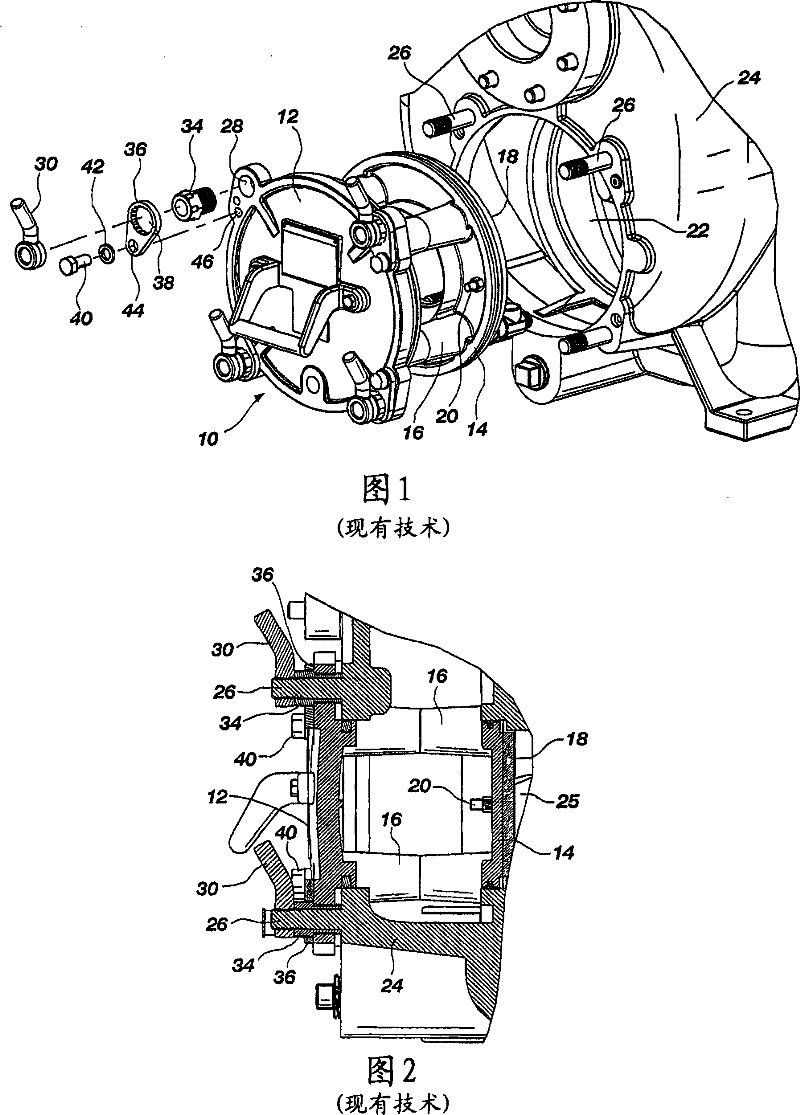

[0021] A prior art purge assembly 10 is shown by comparison in FIGS. 1 and 2 and generally includes an end cap 12 and a support ring 14 , wherein the support ring 14 is spaced from the end cap 12 by a plurality of struts 16 . The support ring 14 provides means for attaching thereto a wear plate 18 which is attached to the support ring 14 by screws 20 . Scavenger assembly 10 fits into opening 22 formed in pump housing 24 so that wear plate 18 is positioned adjacent impeller 25, as shown in FIG. 2 .

[0022] In the prior art pump shown in FIG. 1 , the purge assembly 10 is attached to the pump housing 24 by a plurality of stud bolts 26 which extend through holes 28 formed in the end cover 12 . End cap 12 is held in place by hand nut 30 tightened over stud 26 .

[0023] The means for adjusting the axial position of the wear plate 18 relative to the impeller are also connected with the means for connecting the end cover 12 to the pump casing 24 . In particular, a threaded adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com