Method for manufacturing electrodes with small electrode constants

A manufacturing method and technology of small electrodes, which are applied in manufacturing measuring instruments, measuring resistance/reactance/impedance, measuring electrical variables, etc., can solve the problem of less sample usage, increase response value, reduce error, and facilitate transmission hot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

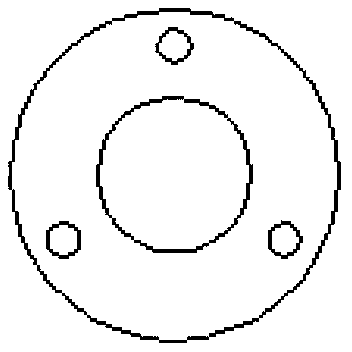

[0021] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 as shown,

[0022] On the edge of the cylindrical plate of the electrode, there are three small round holes with a diameter of about 1 mm, so that when the electrode is immersed in the solution, the gas between the two plates can flow out, otherwise, the existence of the gas will bring problems to the experiment. Large error; special design is made for the PTFE base to fix the cylindrical plate of the inner plate, so that the length of the inner plate is smaller than that of the outer plate, so that the inner electrode plate can be completely covered by the solution during the measurement process. Soaking; therefore, when the solution volume expands or contracts due to temperature changes during the measurement process, the corresponding area between the inner and outer electrode plates remains unchanged; a groove is made on the top of the inner electrode. The phenomenon of capillary rise occu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com