Refrigerating system and ice cream maker

A refrigeration system and condenser technology, applied in the field of refrigeration systems and ice cream machines, can solve the problems of compressor liquid hammer, frequent fluctuations, and unstable refrigerant flow and pressure, so as to ensure sufficient refrigeration, prevent liquid hammer, and improve The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

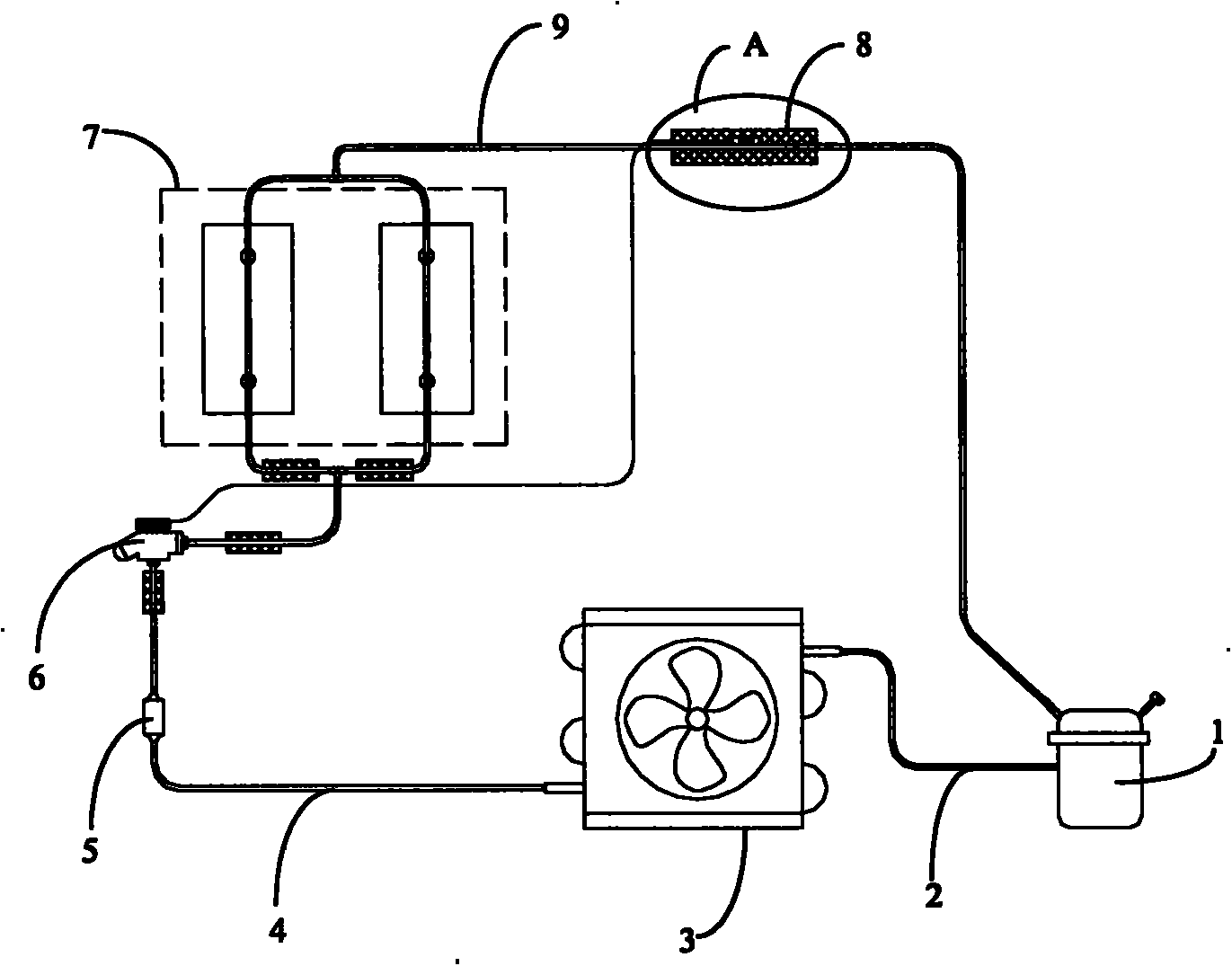

[0022] refer to figure 1 One embodiment of the present invention provides a refrigeration system, including a compressor 1, an exhaust pipe 2, a condenser 3, a condenser outlet pipe 4, a filter 5, a throttling device 6, an evaporator 7, a temperature sensing device 8 and Air return pipe 9, compressor 1 is connected with condenser 3, throttling device 6 and evaporator 7 in sequence, one end of exhaust pipe 2 is connected to the outlet of compressor 1, the other end is connected to the inlet of condenser 3, and the outlet of condenser One end of the pipe 4 is connected to the outlet of the condenser 3, the other end is connected to the inlet of the filter 5, the outlet of the filter 5 is connected to the inlet of the throttling device 6, and one end of the return pipe 9 is connected to the outlet of the evaporator 7 , the other end is connected to the inlet port of compressor 1, compressor 1, condenser 3, throttling device 6 and evaporator 7 form a closed cycle system, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com