Waste heat utilization system for biomass heat-transfer oil furnace

A biomass heat-conducting oil and heat-conducting oil technology, applied in fluid heaters, lighting and heating equipment, dryers, etc., can solve the problems of delaying working hours, consuming manpower to repair and maintain, reducing production efficiency, etc., to avoid waste, Solve the effect of drying heat source and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

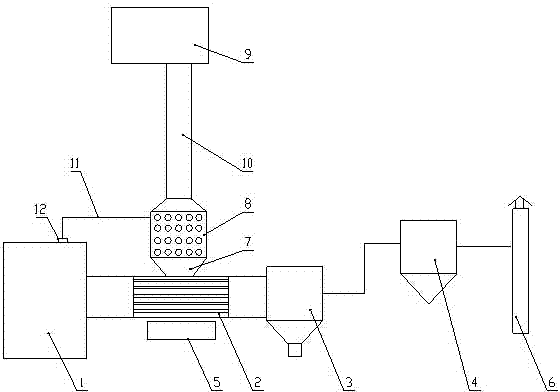

[0013] Such as figure 1 As shown, the biomass heat transfer oil furnace waste heat utilization system of the present invention includes a biomass heat transfer oil furnace 1, a radiator 2 and a dust collector. The dust collector includes a multi-tube dust collector 3 and a high-temperature bag filter 4 connected in sequence, and a chimney 6 is connected to the outlet of the high-temperature bag filter 4 . Radiator 2 is a fin radiator. The fan 5 is an axial fan.

[0014] The left and right sides of the radiator 2 communicate with the biomass heat-conducting oil furnace 1 and the multi-pipe dust collector 3 respectively through pipelines, the rear side of the radiator 2 is provided with a fan 5, and the front side of the radiator 2 is connected with a Heat conduction oil heat exchanger 8, heat conduction oil heat exchanger 8 is connected with airflow dryer 9 through closed waste heat utilization pipeline 10, and the outside of waste heat utilization pipeline 10 is wrapped with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com