Impulse type micro-adjustment oil supply device

An oil supply device, pulse type technology, applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of high price of servo valves, limited number of users, complex mechanical structure, etc., so as to facilitate popularization and application , The control circuit is simple, and the effect of adjustable performance is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

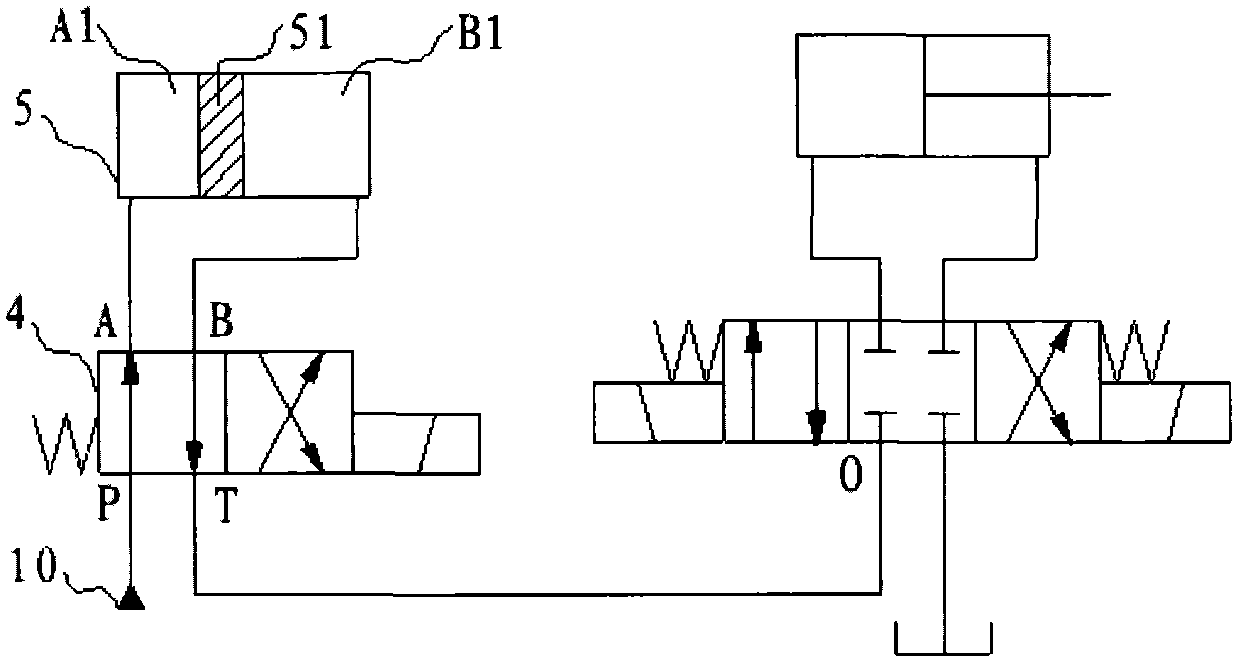

[0013] The present invention will be described in detail below in conjunction with the above-mentioned drawings. The first embodiment: this embodiment is to control the precise positioning of the hydraulic cylinder through the pulse type fine-tuning oil supply device described in the present invention, as shown in the attached figure 2 As shown, the pressure oil source 10 is divided into two circuits, one of which is connected to the P oil port of the directional valve 4 in the pulse type fine-tuning oil supply device of the present invention, and the other is connected and connected to the directional valve 4 after passing through the switching valve 3. The T oil port is connected and connected to the pressure inlet O of the directional valve group M. The pulse type fine-tuning oil supply device includes a volume oil cylinder 5 and a directional valve 4. The directional valve 4 has oil ports P, T, A, B, Among them, oil ports A and B are respectively connected to the left oil ...

no. 2 example

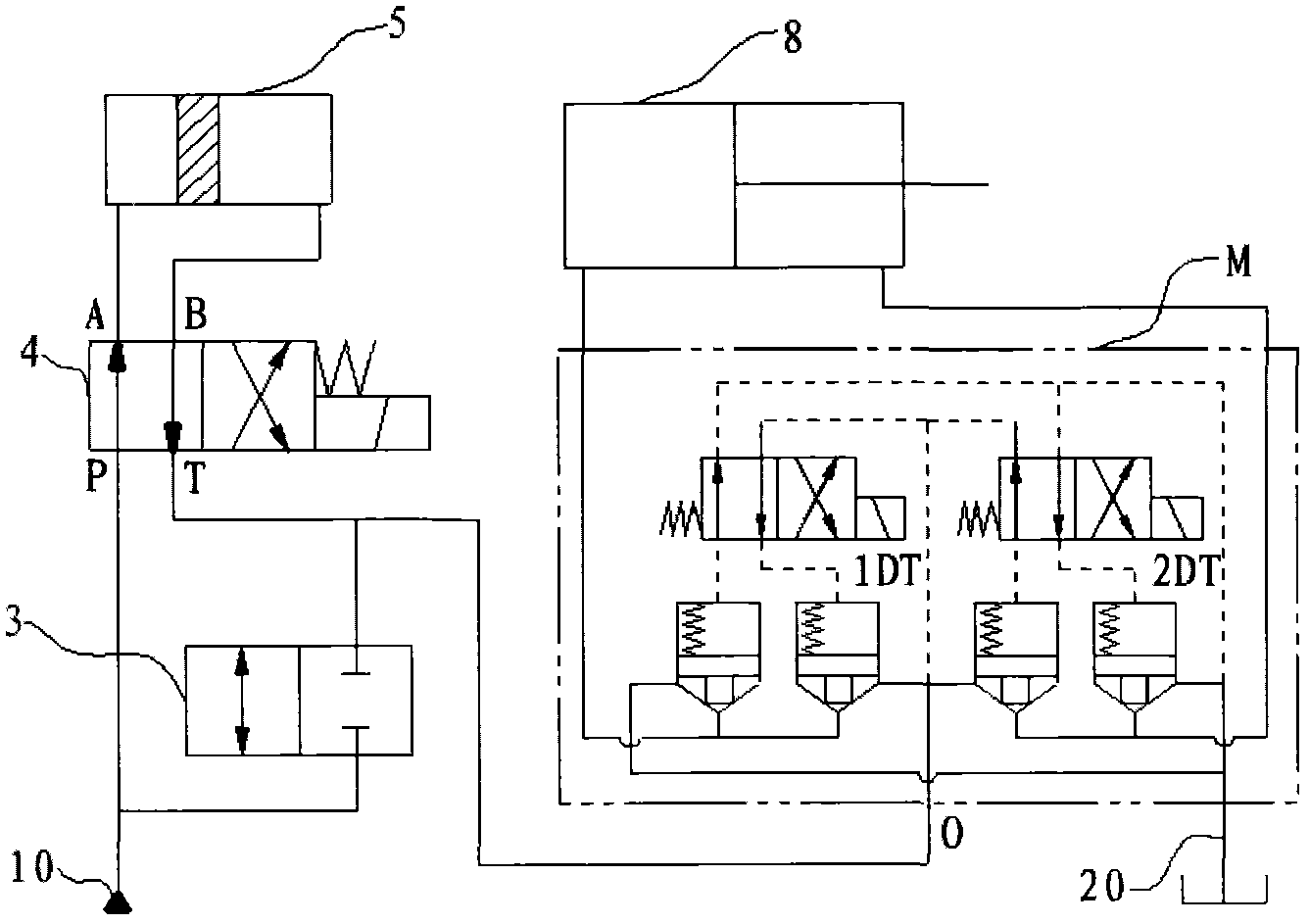

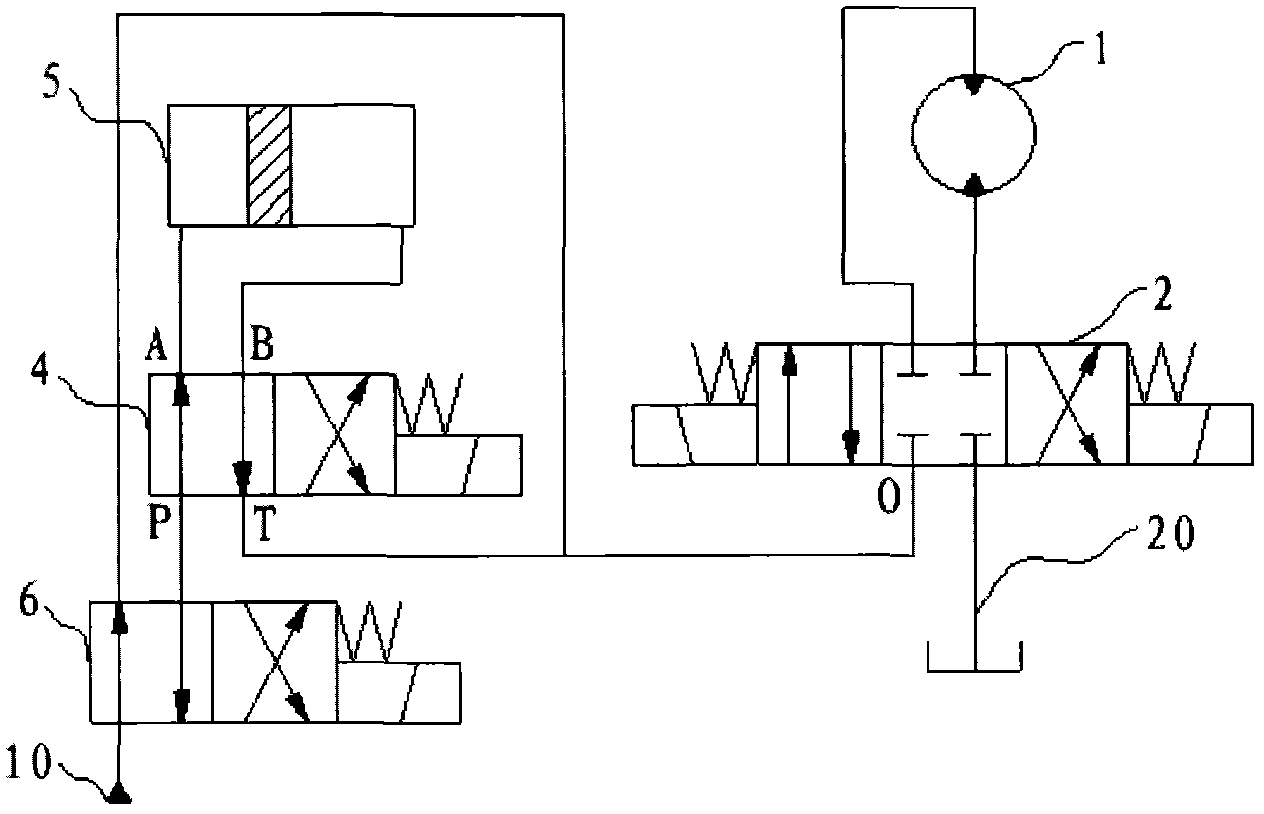

[0015] The second embodiment: this embodiment controls the hydraulic motor to rotate accurately to a predetermined angle position through the pulse-type fine-tuning oil supply device described in the present invention, as shown in the attached image 3 As shown, the pressure oil source 10 is divided into two paths after controlling the directional valve 6 through the pressure channel, and one path is connected with the T port of the directional valve 4 in the pulse type fine-tuning oil supply device according to the present invention and then connected to the directional valve 2 together. pressure inlet O, and the other way is connected to the P oil port of the directional valve 4 in the pulse type fine-tuning oil supply device of the present invention. 4. It has oil ports P, T, A, and B, among which A, B oil ports are respectively connected to the left oil chamber A1 and right oil chamber B1 of the volumetric cylinder 5, and the directional valve 2 is the reversing control val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com