Active dye applied to wool and wool dyeing method

A technology of reactive dyes and dyeing methods for wool, applied in dyeing methods, textiles and papermaking, etc., can solve the problems of high energy consumption for soaping, dyeing sewage, and high dyeing costs, improve the color fastness index, and reduce sewage discharge. , Improve the effect of dyeing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

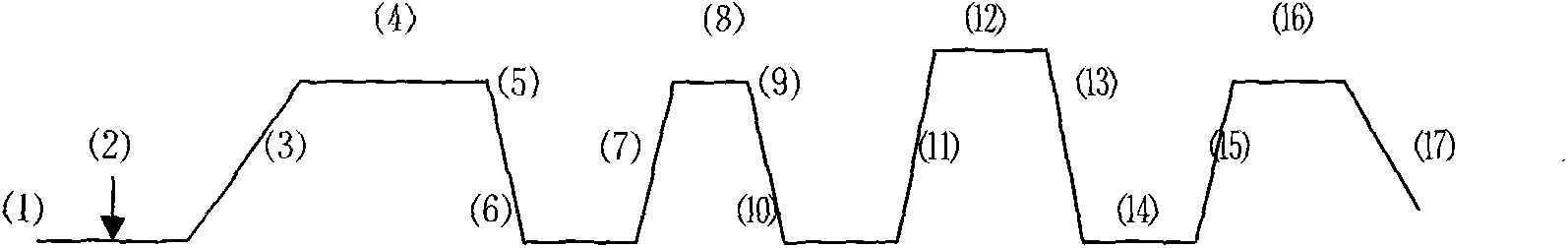

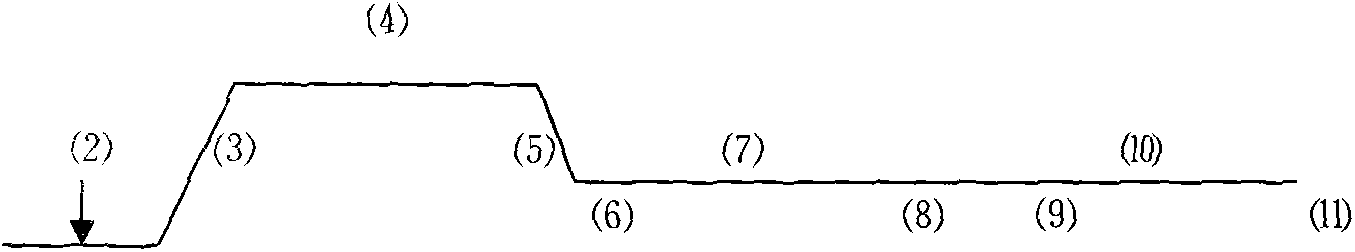

Method used

Image

Examples

Embodiment 1

[0026] 64 wool tops 100KG, dark blue in color, liquor ratio 1:15, dyed. Reactive dye KN-B black 150% 2.5Kg, formic acid 85% 1Kg, acetic acid 98% 1Kg, AlbegalB leveling agent 1Kg, rise to 85°C at 1.5°C / min for 60 minutes, drain. Color fixation: water, add soda ash 6Kg, the temperature is 30°C, the time is 30 minutes, and the water is drained. Neutralization: enter water, add 2Kg of acetic acid, run, drain water after 5 minutes, and end the dyeing process.

Embodiment 2

[0028] Cashmere 100Kg, color, bright yellow bath ratio 1:15, dyeing: add reactive dye KN-G yellow 0.5Kg, acetic acid 98% 2Kg, AlbegalB1Kg, heat up to 85 ℃ with 1.5 ℃ / min, keep warm for 50 minutes, drain. Color fixation: enter water, add caustic soda 0.5Kg, temperature 40°C, time 20 minutes, drain. Neutralization: enter water, add 1.5Kg of acetic acid, run for 15 minutes to drain. Finish the dyeing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com