Method for manufacturing multifunctional and different functional hemp elastic knitted fabric

A technology for knitted fabrics and manufacturing methods, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of large Young's modulus, itching of human skin, and high crystallinity, so as to improve the problem of itching and bright colors. , the effect of high color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

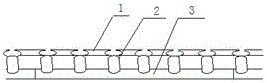

[0034] The manufacturing method of the multi-functional hemp elastic knitted fabric with different functions of the present invention comprises that the moisture-absorbing and quick-drying polyester fiber layer 1 and the hemp fiber layer 3 are woven and connected through the middle connection layer 2 .

[0035] 1. Spinning process

[0036] According to the proportion of 30% hemp and 70% cotton by mass, 40 hemp blended yarns are spun by ordinary ring spinning frame and smooth spinning technology, and the yarn dryness reaches the level of 25% of Uster. , the hairiness is reduced by 30%, and the strength is increased by 5%, which meets the requirements of knitting yarn.

[0037] 2. Winding process:

[0038] The automatic winding machine is used to wind the small yarn into a large-capacity and well-formed cheese for the circular knitting machine, and remove the defects and impurities on the yarn.

[0039] 3. Knitting process:

[0040] In the present invention figure 1 , figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com