A kind of preparation method of lipophilic hydrophobic membrane-covered proppant

A technology of hydrophobicity and proppant, applied in chemical instruments and methods, earthwork drilling, drilling composition, etc., can solve the problem of low crude oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

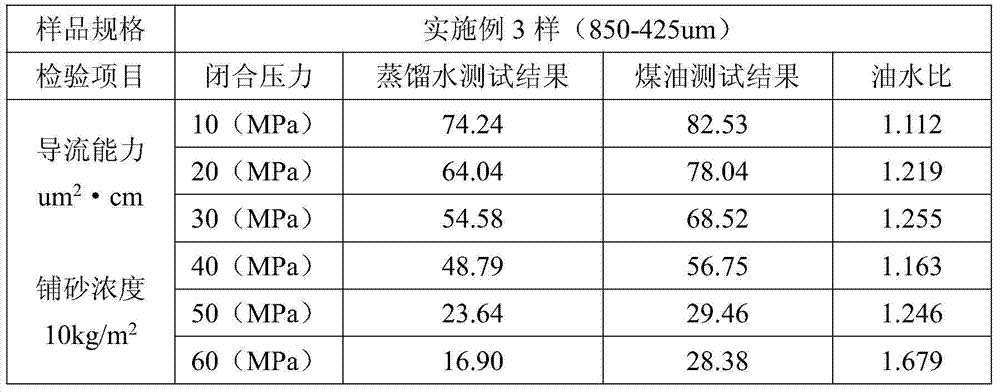

Examples

preparation example Construction

[0020] The preparation process of the lipophilic hydrophobic film-coated proppant of the present invention is as follows:

[0021] Raw materials in parts by weight: 100 parts of quartz sand and ceramsite aggregate; 3-5 parts of thermoplastic resin; 0.5-2 parts of petroleum pitch; 0.05-0.2 parts of silane coupling agent; 0.3-0.6 parts of plasticizer; ~0.6; dispersant 0.1~0.4.

[0022] The thermoplastic resin and the petroleum pitch are mixed and heated to 70-100° C., melted, stirred and kneaded for 10-30 minutes to obtain the mixed resin. Weigh 20-40 mesh quartz sand and ceramsite mixed aggregate and put it into the resin sand mixer and heat it to 140-230°C, then add silane coupling agent, mixing resin, plasticizer and amine curing agent in turn under stirring, Stir until there is a sign of dispersion, add a dispersant, discharge, cool, and sieve to obtain a lipophilic and hydrophobic film-coated proppant.

[0023] Optimally, the thermoplastic resin is a mixture of any two or...

Embodiment 1

[0030] Preparation of lipophilic and hydrophobic mixing resin: Weigh 15g of epoxy resin and 15g of phenolic resin, mix and stir, heat to 90°C, melt, stir and knead for 25min.

[0031] Preparation of film-coated proppant: Weigh 1kg of 20 / 40 mesh quartz sand and put it into a resin sand mixer, heat it to 180°C, add 0.5g of silane coupling agent KH550 under stirring, add the mixed resin after 20s, and then add 3g Continue to stir the dimethyl phthalate for 30s, add 3g of hexamethylenetetramine, stir and solidify until there are signs of dispersion, add 1g of calcium stearate to disperse for 10s, discharge, cool, and sieve to obtain lipophilic and hydrophobic coatings. membrane proppant.

Embodiment 2

[0033] Preparation of lipophilic and hydrophobic mixed resin: Weigh 15g epoxy resin, 15g phenolic resin and 5g petroleum pitch, mix and stir, heat to 90°C, melt, stir and knead for 25min.

[0034] Preparation of film-coated proppant: Weigh 1kg of 20 / 40 mesh quartz sand and put it into a resin sand mixer, heat it to 180°C, add 0.5g of silane coupling agent KH550 under stirring, add the mixed resin after 20s, and then add 3g Continue to stir the dimethyl phthalate for 30s, add 3g of hexamethylenetetramine, stir and solidify until there are signs of dispersion, add 1g of calcium stearate to disperse for 10s, discharge, cool, and sieve to obtain lipophilic and hydrophobic coatings. membrane proppant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com