Nanometer alpha-Fe2O3 functional modified PVA-base composite coated fresh-keeping package material and preparation method thereof

A technology for coating fresh-keeping and packaging materials, which is applied in the field of food packaging materials, can solve the problems of yellowing on the surface of coating packaging of egg products, poor water resistance and moisture resistance, etc. The effect of water resistance and film-forming barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

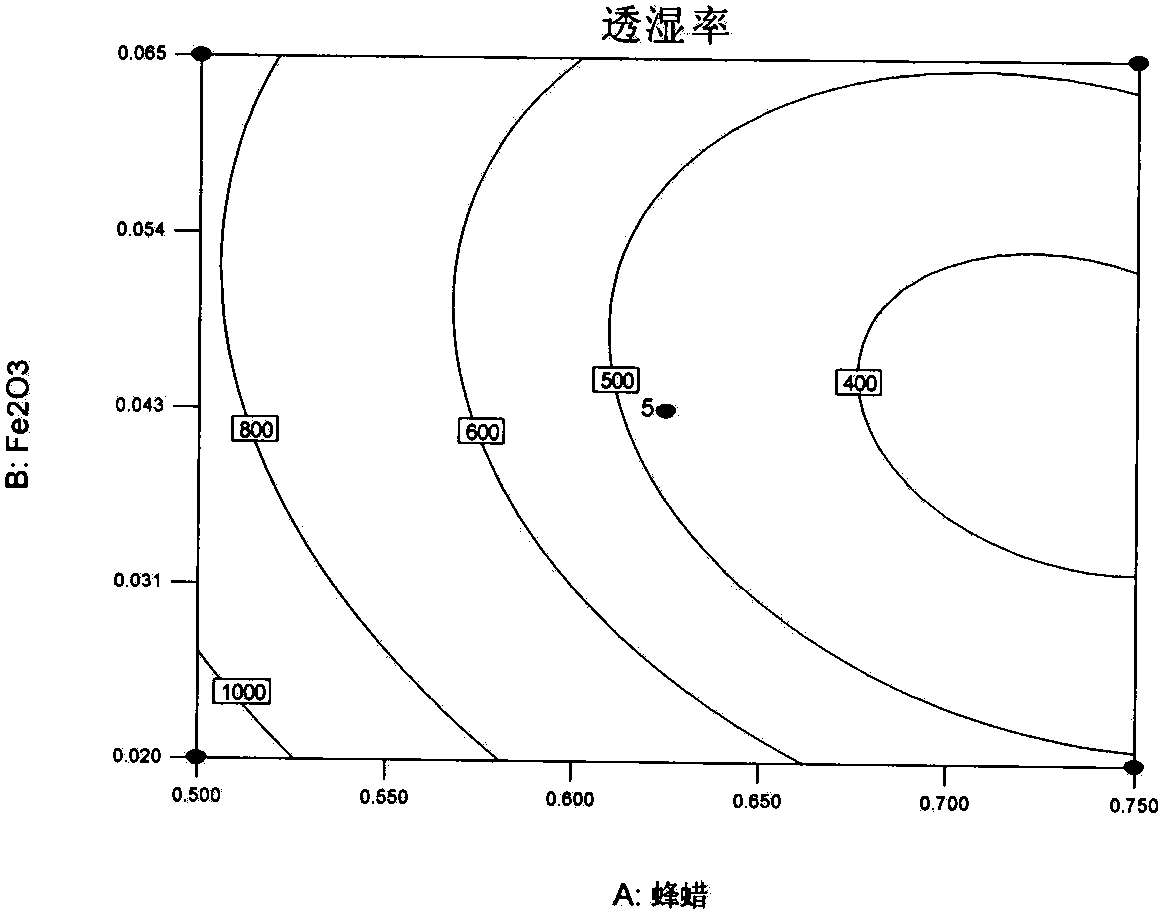

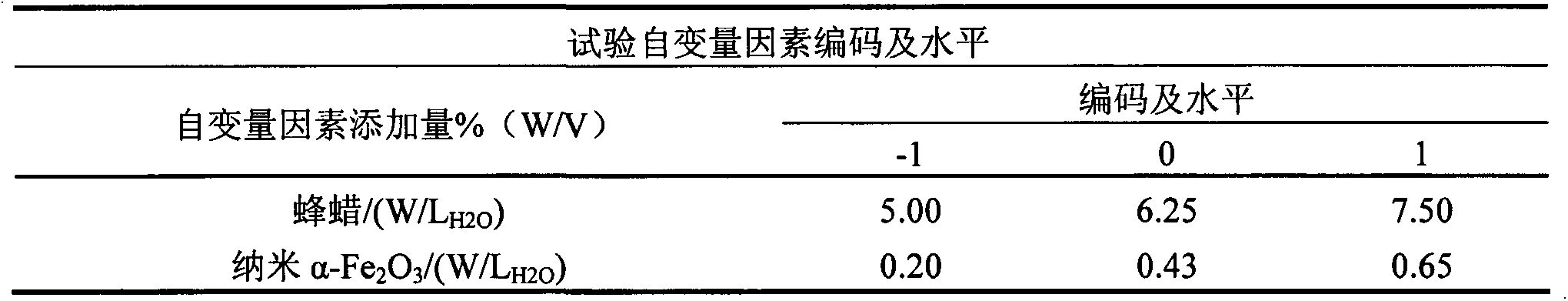

[0025] Example 1: Nano α-Fe 2 O 3 Functional modified PVA-based composite coating film fresh-keeping packaging material preparation response surface test: nano α-Fe 2 O 3 And the dosage of beeswax is designed according to the response surface test in the table below

[0026] Table 1 Composite coating material α-Fe2O3, beeswax added amount response surface experimental design

[0027]

[0028] Add nano α-Fe to 50g / L PVA aqueous solution 2 O 3 (Dispersed in 10ml of absolute ethanol), then add polyglycerol ester, place in an ultrasonic water bath, sonicate for 15min under the condition of power density 65W / L, nano-α-Fe 2 O 3 After being uniformly dispersed in the PVA solution, the mixture is stirred and heated to 85°C to react at a constant temperature until the PVA is completely dissolved, and then the monoglyceride is added to the melted beeswax (polyglycerol: monoglyceride = 1:0.03), the added amount accounts for the beeswax 60% of the mass, the PVA mixed solution was slowly poured ...

Embodiment 2

[0034] Example 2: Add 0.43g / L nano α-Fe 2 O 3 Disperse into 10ml of absolute ethanol, then add to 50g / L of PVA aqueous solution, add a surfactant polyglycerol ester 0.42g / L (W / L H2O ), placed in an ultrasonic water bath, sonicated for 25 minutes at a power density of 65W / L to make the nano α-Fe 2 O 3 Disperse uniformly in the polyvinyl alcohol aqueous solution; the mixed solution is stirred and heated to 85°C to react at a constant temperature until the PVA is completely dissolved, and then another surfactant monoglyceride 1.26g / L is added to the melted 7.36g / L beeswax. Then, the mixed PVA aqueous solution was slowly poured into beeswax three times, and the crosslinking reaction was stirred for 90 minutes at a constant temperature of 85°C; then stirred and cooled to room temperature to prepare a nano-modified composite coating packaging material, and testing the composite coating fresh-keeping packaging material Film-forming efficiency, the moisture permeability is 401.80g / m 2 *h...

Embodiment 3

[0035] Example 3: Add 0.43g / L nano α-Fe 2 O 3 Disperse into 10ml absolute ethanol, then add to 50g / L PVA aqueous solution, sonicate for 25 minutes under the power density of 65W / L to make nano α-Fe 2 O 3 Disperse uniformly in the polyvinyl alcohol aqueous solution; the mixture is stirred and heated to 85°C to react at a constant temperature until the PVA is completely dissolved, then stirred and cooled to room temperature to prepare nano-α-Fe 2 O 3 Modified composite coating film packaging material.

[0036] In the 50g / L PVA aqueous solution, add a surfactant polyglycerol ester 0.42g / L (W / L H2O ), placed in an ultrasonic water bath, sonicated for 25 minutes at a power density of 65W / L, the mixture was stirred and heated to 85°C to react at a constant temperature until the PVA was completely dissolved, and another surfactant monoglyceride 1.26g / L was added to In the melted 7.36g / L beeswax. Then, the mixed PVA aqueous solution was slowly poured into beeswax in three times, and the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com