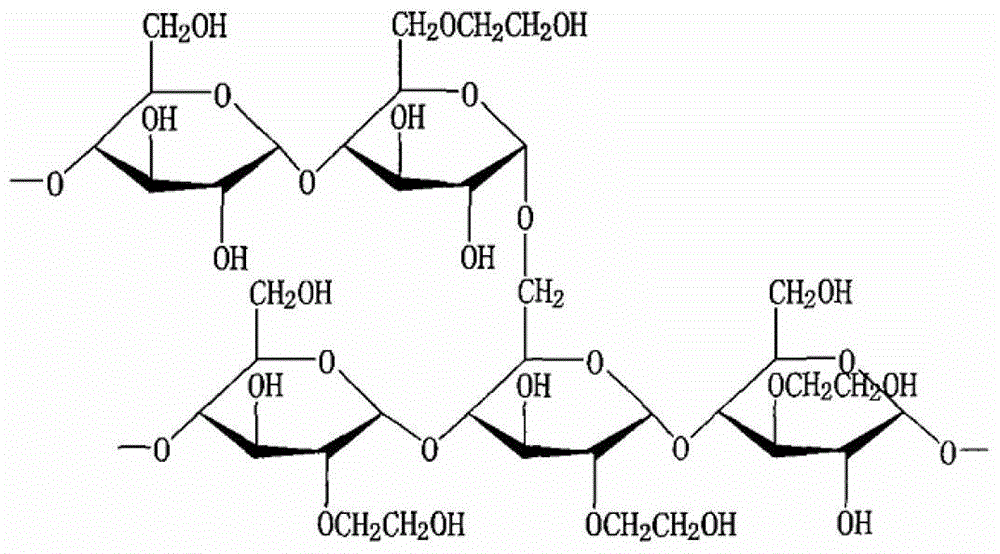

Purification method of hydroxyethyl starch

A technology of hydroxyethyl starch and a purification method, which is applied in the field of purification of hydroxyethyl starch, can solve problems such as the limitation of removing bacterial endotoxin, the loss of main drug components, and the impact on yield, so as to reduce the level of bacterial endotoxin and improve the internal Quality, easy-to-handle results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

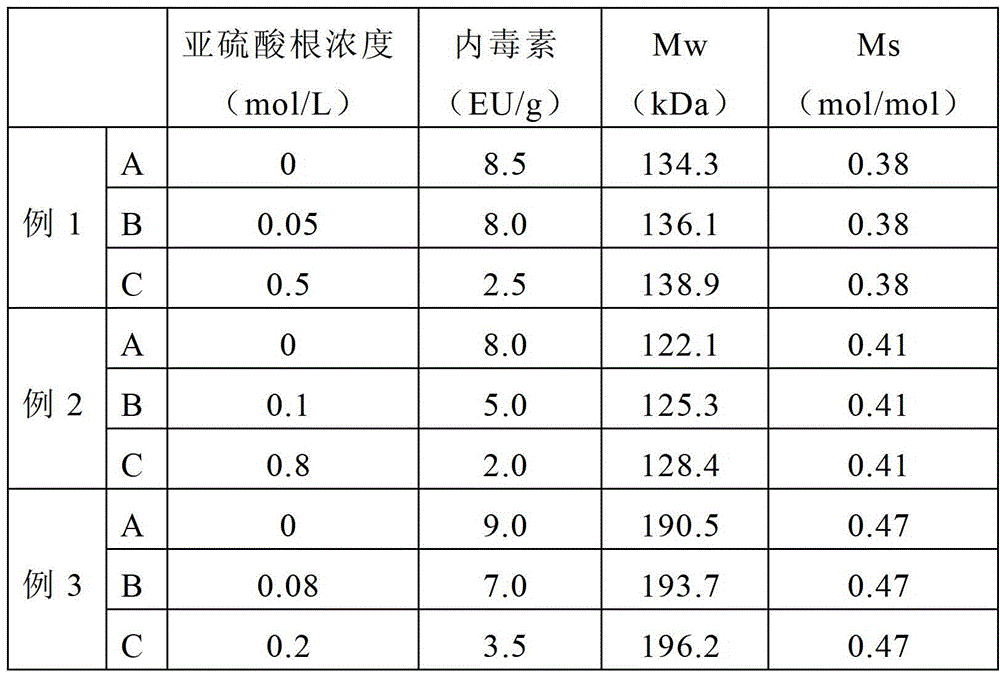

[0053] A method for preparing hydroxyethyl starch, the method comprising: using sulfurous acid, bisulfite, and sulfite to help dissolve endotoxins, reducing the association of macromolecules such as endotoxins in water, and endotoxins are easily absorbed during ultrafiltration. remove;

[0054] Preferably, the sum of the concentrations of sulfurous acid, bisulfite and sulfite used for solubilization is 0.05-1.0 mol / L.

[0055] Preferably, the sulfurous acid, bisulfite, and sulfite used for solubilization can be one or more of sulfurous acid solution, sulfite, and bisulfite.

[0056] A specific embodiment of the present invention can be:

[0057] The purification method of hydroxyethyl starch of the present invention can be included in the preparation method of following hydroxyethyl starch, wherein, the preparation method of described medium molecular weight hydroxyethyl starch comprises the following steps:

[0058] 1) Starch hydrolysis: use purified water as solvent, disso...

example 1

[0078] 1) Hydrolysis

[0079] Add 3300ml of water to a 10L reaction kettle, stir, add 1000g of pharmaceutical grade starch, add 25ml of concentrated hydrochloric acid, heat up to 90°C, keep warm at 89-92°C, take samples every 10 minutes, and quickly measure the viscosity. At 1 minute and 25 seconds, stop heating and quickly cool down to 19-20°C.

[0080] 2) Etherification

[0081] Dissolve 35g of solid sodium hydroxide into 590ml of water and cool to 19-20°C. Slowly add the obtained NaOH solution into the hydrolysis mixture obtained in step 1) under stirring conditions, keep the temperature at 19-20°C, seal the etherification tank, vacuumize, slowly introduce 90g of ethylene oxide, and seal the reaction for 8 hours. The reaction is complete.

[0082] 3) Adsorption

[0083] Adjust the pH to 7.5 with concentrated hydrochloric acid. Under stirring, add 1750ml of mixed solvent of water and ethanol (volume ratio 1:3), stir fully, and let it stand; take the upper layer, use 15....

example 2

[0090] 1) Hydrolysis

[0091] Add 3500ml of water to a 10L reactor, stir, add 1000g of pharmaceutical grade starch, add 250ml of concentrated hydrochloric acid, heat up to 90°C, keep warm at 89-92°C, take samples every 10 minutes, and measure the viscosity quickly. At 1 minute and 20 seconds, stop heating and quickly cool down to 21-23°C.

[0092]2) Etherification

[0093] Dissolve 125g of solid sodium hydroxide into 700ml of water and cool to 19-20°C. Slowly add the obtained NaOH solution into the hydrolysis mixture obtained in step 1) under stirring conditions, keep the temperature at 21-23°C, seal the etherification tank, vacuumize, slowly introduce 115g of ethylene oxide, and seal the reaction for 5 hours. The reaction is complete.

[0094] 3) Adsorption

[0095] Adjust the pH to 5.5 with concentrated hydrochloric acid. Under stirring, add 2500ml of mixed solvent of water and ethanol (volume ratio 1:3), stir fully, and let it stand; take the upper layer, use 20.0g of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com