Decoloring method of crude styrene obtained through extractive rectification of pyrolysis gasoline C8 fraction

A technology of crude styrene and pyrolysis gasoline, applied in the direction of chemical change purification/separation, organic chemistry, etc., can solve problems such as water content, equipment corrosion, etc., achieve the effects of reducing sewage discharge, preventing equipment corrosion, and reducing acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

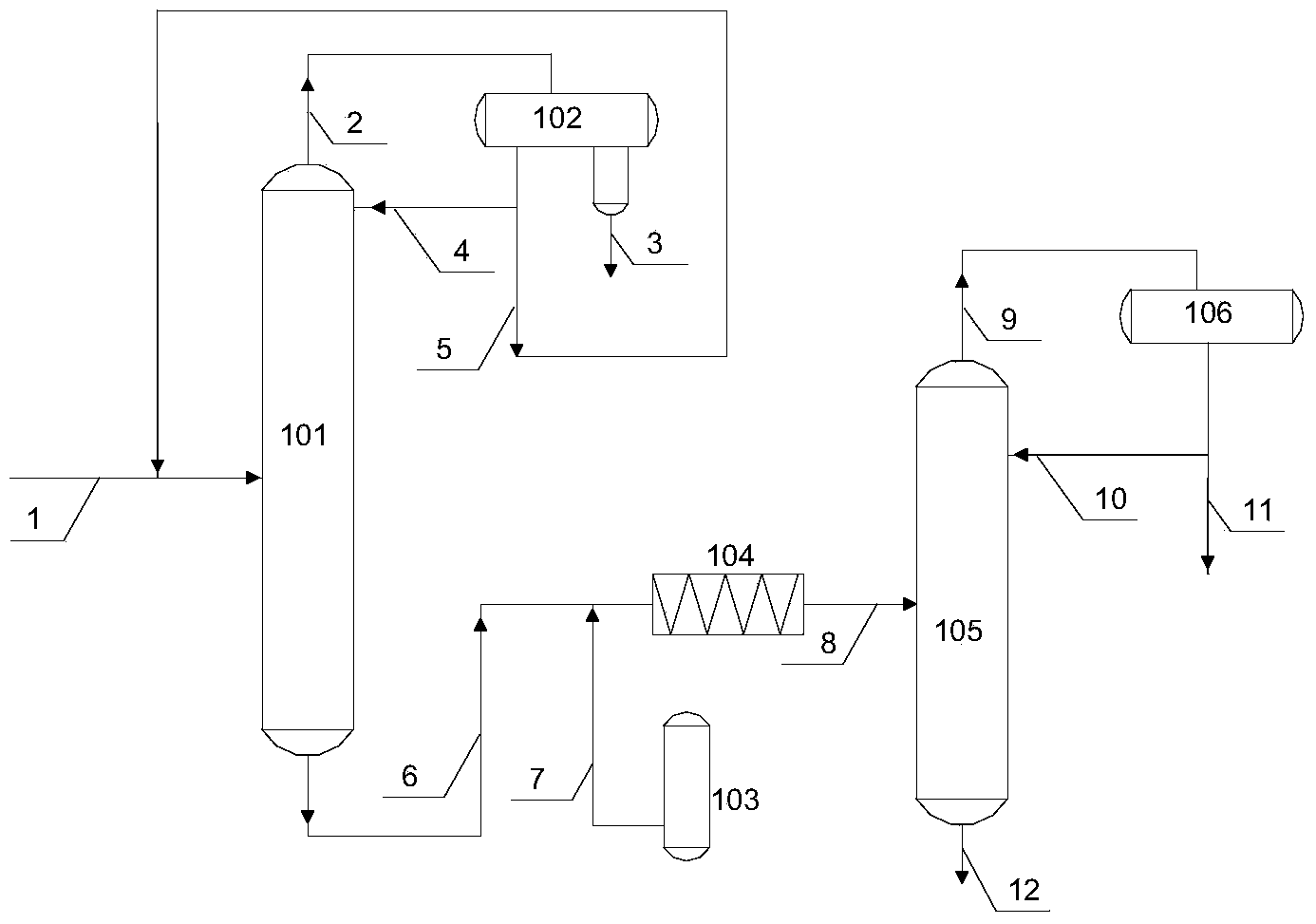

[0027] according to figure 1 Process for pyrolysis gasoline C 8 The distillate is decolorized with the crude styrene obtained by extractive distillation.

[0028] pyrolysis gasoline C 8 The crude styrene obtained by extraction and rectification of the distillate has a purity ≥ 99.7% by mass and a water content of 594 μg / g, and enters the middle part of the dehydration tower 101 . The number of plates in the dehydration tower is 20, the reflux ratio at the top of the tower is 1, the pressure at the top of the tower is 8kPa, and the distillation temperature at the top of the tower is 62°C. The azeotrope of styrene and water is obtained at the top of the tower. After the water is separated from the water in the condensate tank 102, the water is discharged from the system, and a part of the oil is returned to the feed pipeline, and the other part is used as a reflux at the top of the tower. The water content of the dehydrated styrene obtained at the bottom of the tower is <40 μ...

example 2

[0031] By the method of example 1 to pyrolysis gasoline C 8The distillate is decolorized with the crude styrene obtained by extractive distillation. The difference is that benzene is added to the crude styrene as a dehydrating agent, the amount of benzene added is 3% by mass of the feed amount of the dehydration tower, the number of dehydration trays is 25, the top reflux ratio is 1.2, the pressure is 60kPa, and the top distillation temperature 105°C. The stream discharged at the top of the dehydration tower 101 is an azeotrope of benzene and water and a small amount of styrene. After the water separation in the condensate tank 102, the resulting oil phase is benzene and a small amount of styrene, and a part is used as the top reflux. The rest is used as a dehydrating agent and mixed with raw materials. The water content of the dehydrated styrene obtained at the bottom of the dehydration tower is ≤10 μg / g.

[0032] In the decolorizer tank 103, there is a dioctyl phthalate s...

example 3

[0034] By the method of example 1 to pyrolysis gasoline C 8 The distillate is decolorized with the crude styrene obtained by extractive distillation. The difference is that benzene is added to the crude styrene as a dehydrating agent, the amount of benzene added is 3% by mass of the feed amount of the dehydration tower, the number of dehydration trays is 30, the top reflux ratio is 0.8, the pressure is 60kPa, and the top distillation temperature 105°C. The stream discharged at the top of the dehydration tower 101 is an azeotrope of benzene and water and a small amount of styrene. After the water separation in the condensate tank 102, the resulting oil phase is benzene and a small amount of styrene, and a part is used as the top reflux. The rest is used as a dehydrating agent and mixed with raw materials. The water content of the dehydrated styrene obtained at the bottom of the dehydration tower is ≤10 μg / g.

[0035] The decolorizer in the decolorizer tank 103 is dioctyl pht...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com