Carbon-coated metal-doped zinc oxide composite photocatalysis nano material and preparation method thereof

A technology of composite photocatalysis and nanomaterials, which is applied in the field of carbon-coated metal-doped zinc oxide core-shell structure nanorod-shaped composite photocatalytic materials, which can solve the problems of unsystematic research on the influence of photocatalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Carbon-coated metal-doped zinc oxide composite photocatalytic nanomaterial is a material with visible light catalytic activity. The material has a rod-shaped core-shell structure. The layer coating thickness is 7-12.5 nm. Its preparation method comprises the following steps:

[0032] (1) Preparation of precursor solution:

[0033] Dissolve zinc salt and doped metal salt in 20mL alcohol solvent, in which the total molar weight of metal ions is 5mmol, and the doping concentration of metal ions is 1-5mol%, then add 10-50mmol of sodium hydroxide, and stir to obtain a precursor solution ;

[0034] (2) Put the precursor solution in a high-pressure reactor, seal it, and react at 120-160°C for 2-12 hours;

[0035] (3) Cool to room temperature after the reaction, wash the product repeatedly with absolute ethanol, and dry at 60°C for 2–6 hours to obtain metal ion-doped zinc oxide Zn 1-x m x O rod-shaped photocatalytic nanomaterials. Zn 1-x m x O nanorods are 200-500nm lon...

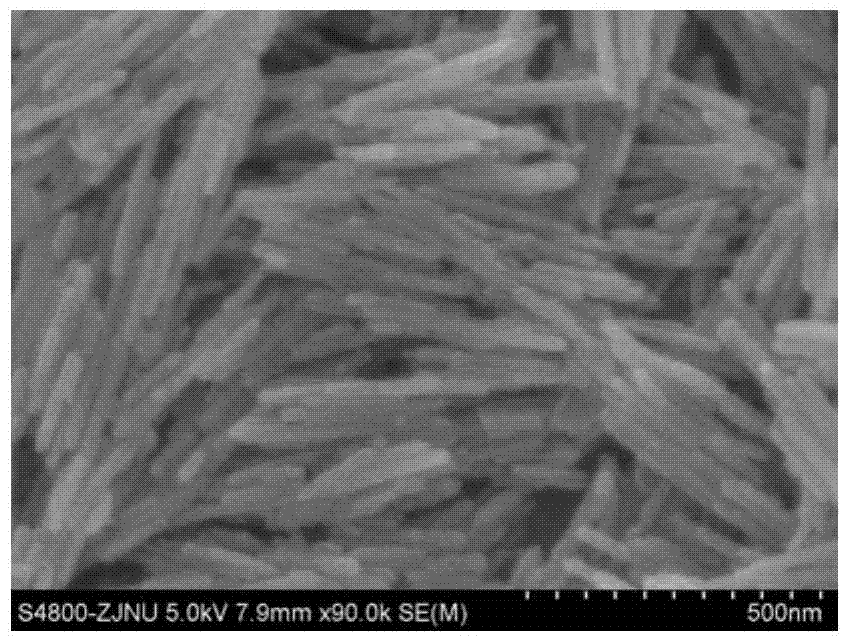

Embodiment 1

[0040] 1.087g (4.95mmol) zinc acetate and 0.05mmol (0.012g) nickel acetate are dissolved in 20mL methanol, wherein the total molar weight of metal ions is 5mmol, and the nickel ion doping concentration is 1mol%, then add 50mmol of sodium hydroxide, Stir to obtain a precursor solution; place the precursor solution in a high-pressure reactor, seal it, and react at 140°C for 2h; after the reaction, cool to room temperature, wash the product repeatedly with absolute ethanol, and dry at 60°C for 2h to obtain nickel-doped zinc oxide Zn 1-x Ni x O rod-shaped photocatalytic nanomaterials. The microstructure of the obtained product is as figure 1 shown.

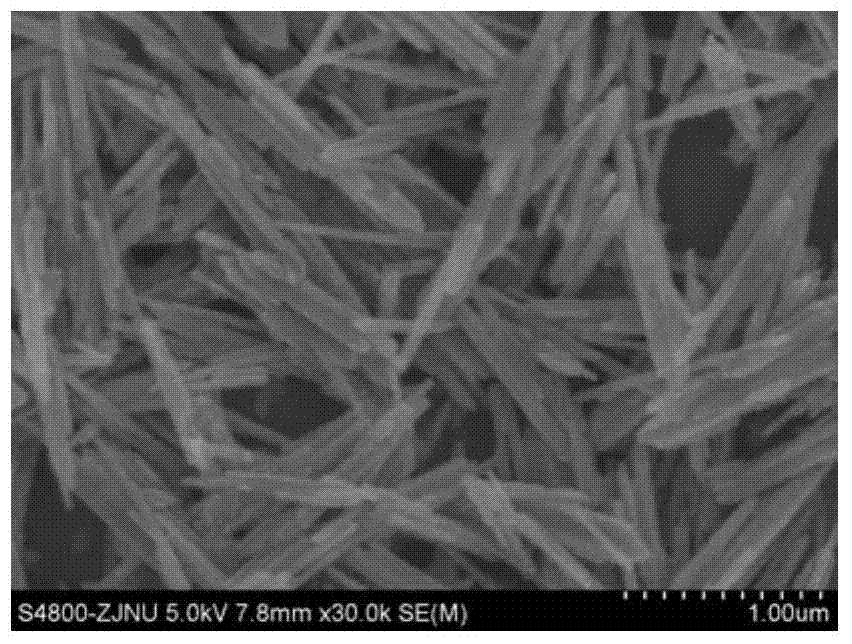

Embodiment 2

[0042] By adopting the technique in Example 1, the amount of zinc salt and nickel salt reactants used is changed to 1.0427g (4.75mmol) and 0.0622g (0.25mmol) respectively, and the nickel ion doping concentration is increased to 5mol%, and nickel doping can also be obtained. ZnO nanorods, such as figure 2 shown. Phase analysis ( image 3 ) shows that the product obtained in Example 1 and Example 2 is Zn 1-x Ni x O system, no other impurity phase exists.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com