High-pressure large-diameter well piping system

A technology of pipeline system and pipeline wall, applied in the field of well pipeline system, can solve problems such as increasing groundwater formation, and achieve the effect of remarkable efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0136] Before describing in detail selected embodiments of the invention, it is to be understood that the invention is not limited to the specific embodiments described herein, but that the invention can be practiced or carried out in various ways.

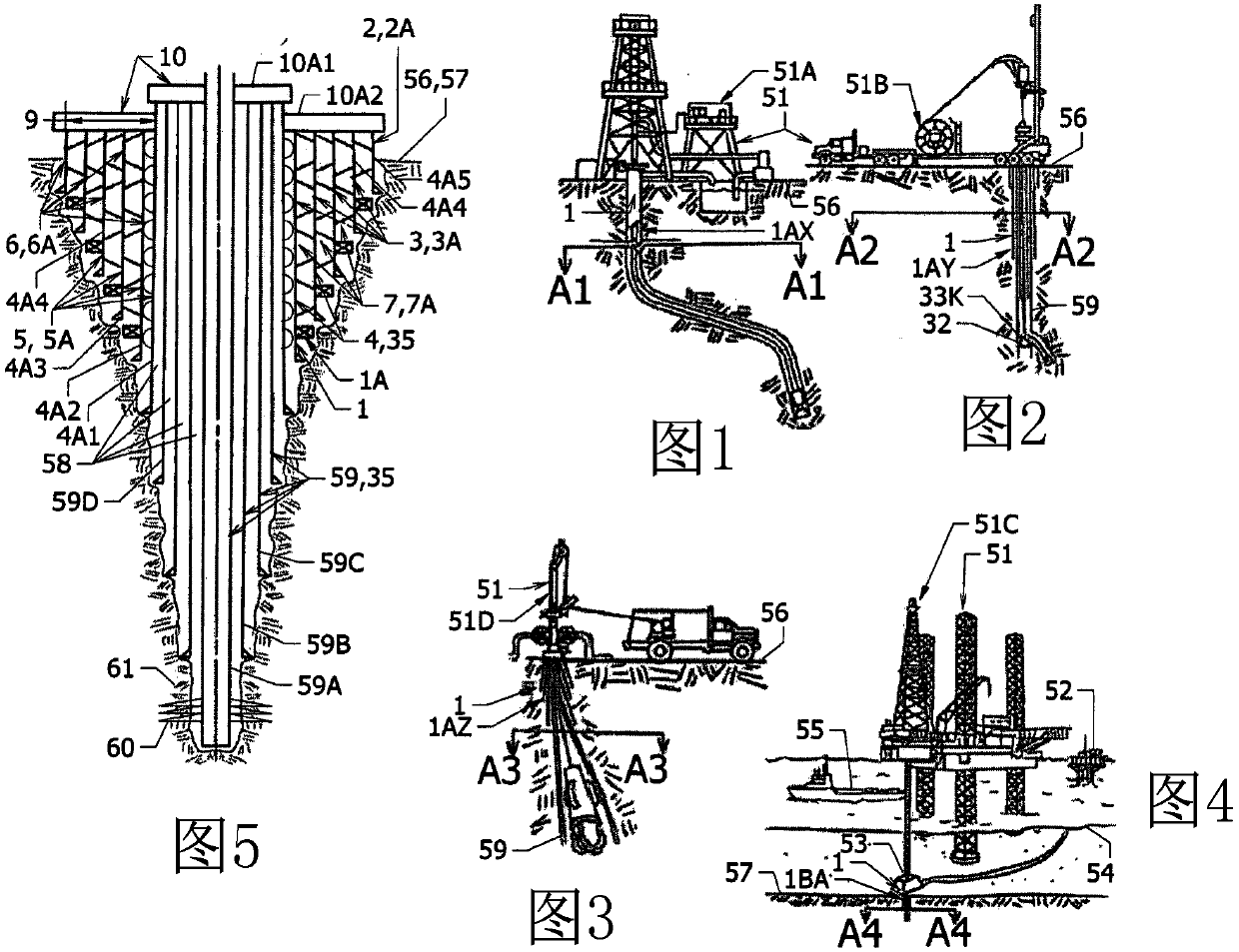

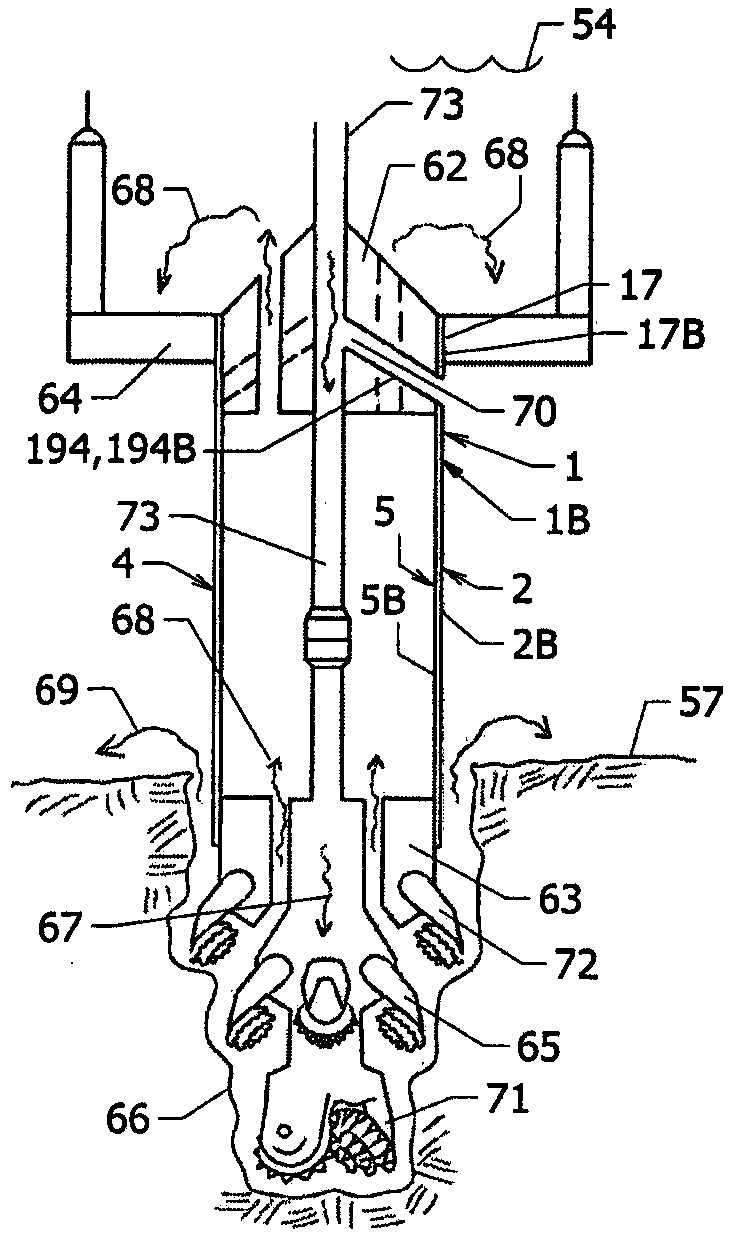

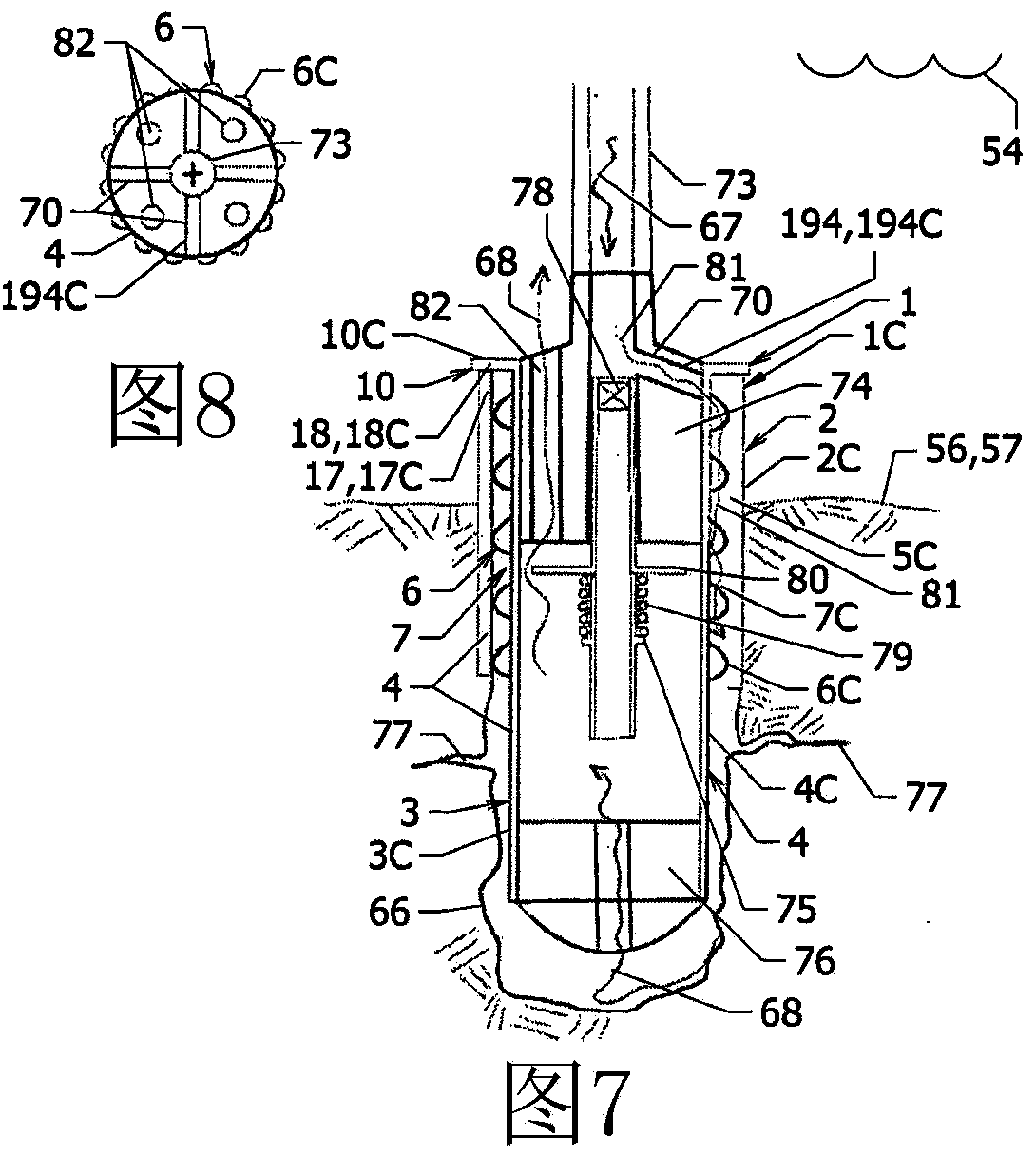

[0137] now refer to figure 1 , 2 . The arrangement of the prior art coiled pipe drilling (51B) rig (51), the wireline drilling (51D) rig (51) above the line A3-A3 and the prior art offshore drilling above the line A4-A4 Schematic illustration of a cross-sectional portion of a spud drilling (51C) drill frame (51) through the environment and subterranean formations. About attached Figure 1-4 , any drilling frame including the described drilling frame (51) can be used to operate and / or drill within the large diameter high pressure piping system (1); however, the larger lifting capacity drilling frames (51A and 51C) It is generally preferred for installing said piping system (1), especially when these drill stands are suitable f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com