Laser and manufacturing method thereof

A manufacturing method and laser technology, applied in the field of lasers, can solve the problems of reducing the conversion efficiency of the carrier transport capability of the laser and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

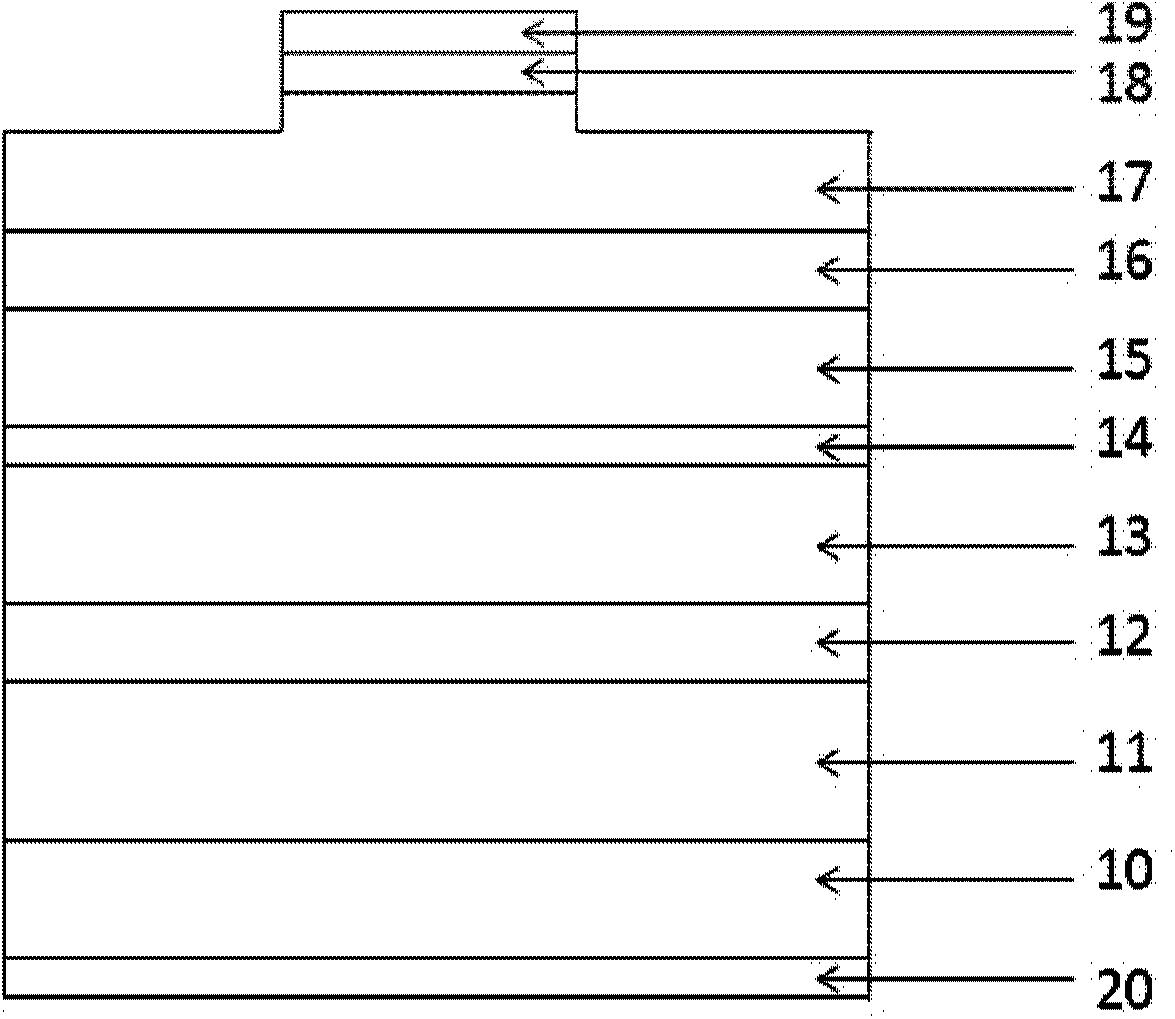

[0008] figure 1 A schematic structural diagram of a laser proposed by the present invention is shown. Such as figure 1 As shown, the laser includes:

[0009] -N-type gallium arsenide substrate 10;

[0010] -N-type cladding layer 11, the N-type cladding layer 11 is fabricated on the N-type gallium arsenide substrate 10;

[0011] - superlattice layer 12, this superlattice layer 12 is made on the N-type cladding layer 11;

[0012] -N-type waveguide layer 13, the N-type waveguide layer 13 is made on the superlattice layer 12;

[0013] - active layer 14, this active layer 14 is made on the N-type waveguide layer 13;

[0014] - P-type waveguide layer 15, the P-type waveguide layer 15 is fabricated on the active layer 14; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com