Method for recognizing torsion mode and bending mode in mode test

A technology of torsional mode and bending mode, which is applied in the identification of modal parameters of body-in-white, the identification of torsional mode and bending mode in modal tests, and can solve the problem that the first-order torsional and bending modes are difficult to accurately identify, etc. problem, to achieve the effect of improving the accuracy of judgment and the efficiency of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following combination Figure 1~3 , the content of the present invention will be described in detail through specific embodiments.

[0019] 1) Point selection position:

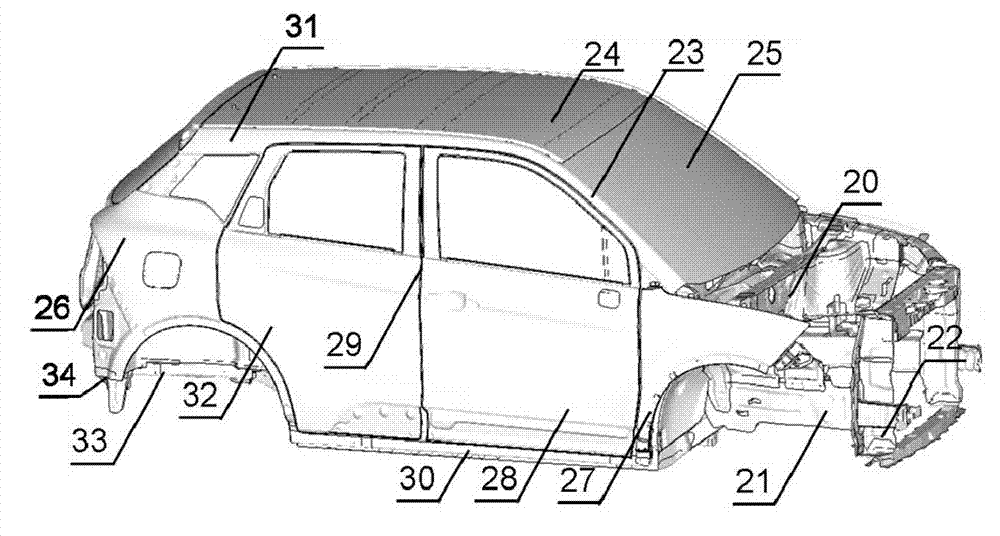

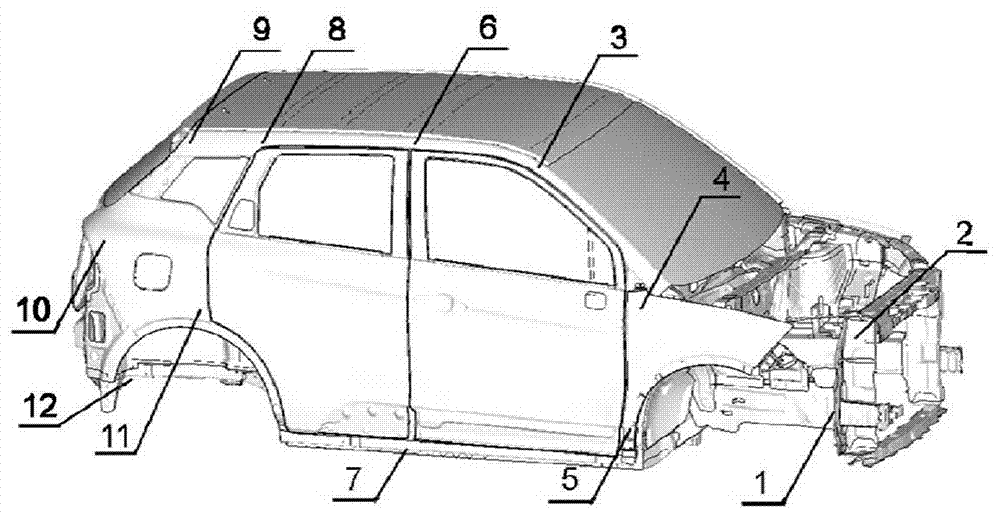

[0020] like figure 1 As shown, 12 contour points representing the body structure are symmetrically selected on the left and right sides of the car TB. These points should be at the positions where the frame structure of the body is more rigid. The corresponding body structure is as follows figure 2 shown. For ease of viewing, only the schematic diagram of points taken under the state of body-in-white and door cover system is shown. Take points 1 and 2 at the front end of the vehicle body, point 1 is the junction of the front longitudinal beam 21 of the vehicle body and the right column 22 of the water tank, and point 2 is the upper end of the right column 22 of the water tank; Point 5 and point 3 are the joints of the front end of the roof 24, the upper end of the front windshield 25 and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com