Heat-shrinkable wrapping tape

A wrapping tape and heat-shrinking technology, applied in the direction of damage protection, coating, pipe components, etc., can solve problems such as poor adhesion, damage to the anti-corrosion layer, and reduced service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

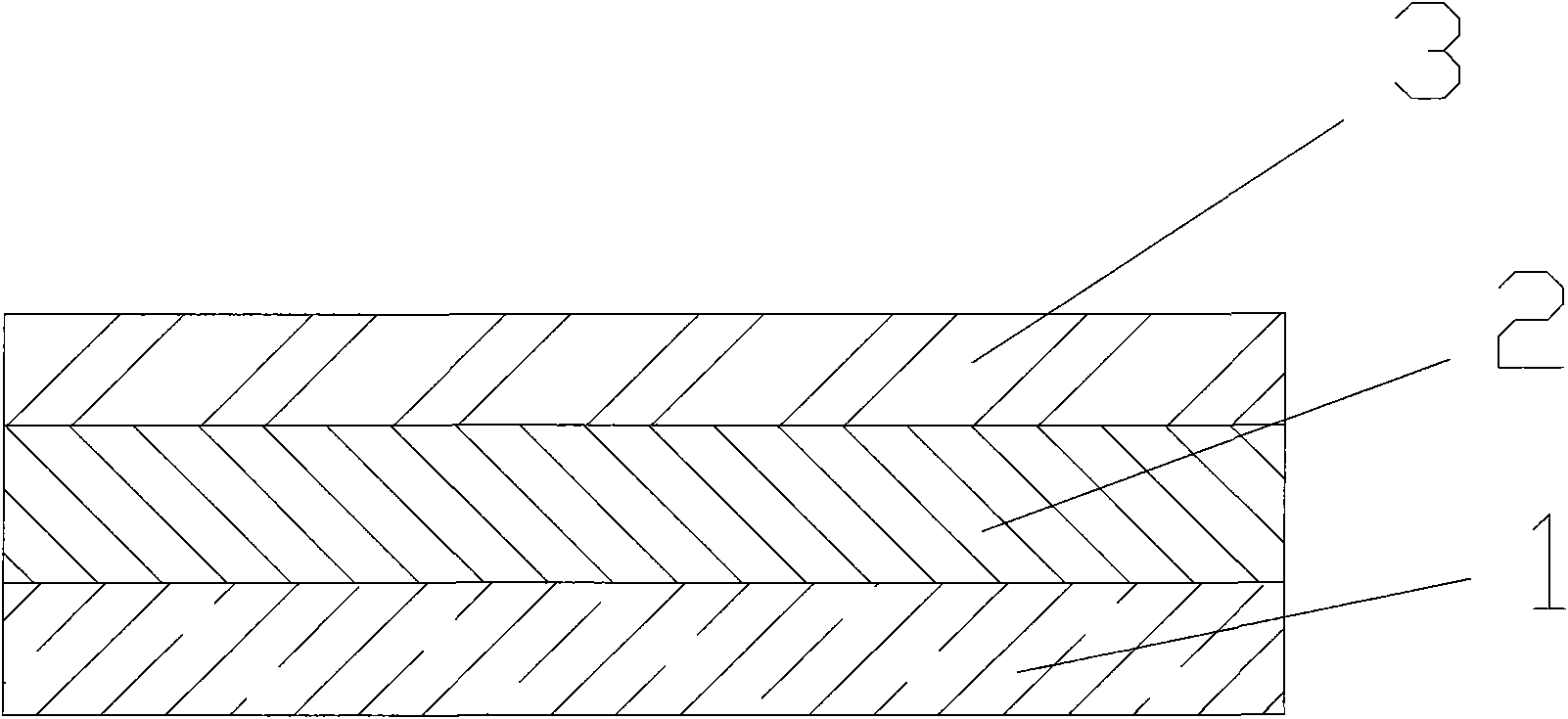

[0010] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0011] Such as figure 1 As shown, the heat-shrinkable winding tape of the present invention has a layered structure, the first layer is a polyethylene base material layer 1, and a hot melt adhesive layer 2 and a solid epoxy coating layer 3 are sequentially arranged on the polyethylene base material layer 1. The polyethylene substrate layer 1 is high-density polyethylene that has undergone crosslinking and radiation. The polyethylene base material layer 1 is coated on the three-layer polyethylene pipe. The hot melt adhesive layer 2 has airtightness.

[0012] During the construction of the present invention, firstly, the pipeline is preheated, and the treated pipeline is wrapped by machine or manually to ensure that the lap joint width is not less than 25 mm, and the strip is evenly heated, and the strip shrinks evenly in the radial direction, and at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com