Double-gap high-flow-resistance balance device

A flow resistance balance and double-gap technology, which is applied to parts of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., can solve problems such as reducing equipment reliability and equipment vibration, and achieve Effects of improving reliability, increasing resistance, and increasing gap size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

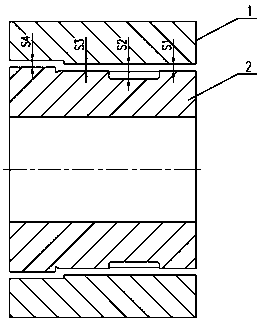

[0016] Such as Figure 1 to Figure 3 As shown, a double-gap high-resistance balance device is composed of a balance drum base 1 and a balance drum 2 .

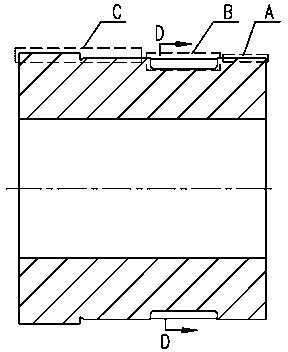

[0017] Such as figure 2 As shown, the balance drum 2 is sequentially provided with a balance drum plane area A, a balance drum water groove area B, and a balance drum double gap irregular zigzag area C from right to left.

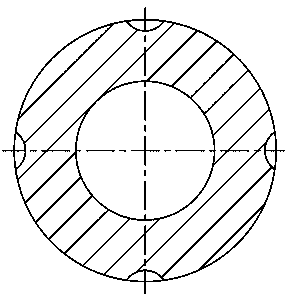

[0018] The balance drum 2 adopts a double-gap structure, and the plane area A of the balance drum adopts a plane structure, forming a radial clearance S1 with the balance drum base. The radial clearance S1 ranges from 0.15 to 0.2mm. inflow; after that, the balance drum tank area B adopts the groove structure arranged in the circumferential direction ( image 3 ) and form a gap S2, the radial gap S2 ranges from 3 to 5mm. After adopting the groove structure, when the balance drum r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial clearance | aaaaa | aaaaa |

| Radial clearance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com