Novel inner rotor five-freedom-degree magnetic suspension vertical axis wind turbine

A technology of wind turbine and inner rotor, which is applied in the field of maglev wind turbine and new type inner rotor maglev vertical axis wind turbine, can solve the problems of shrinking vertical axis maglev wind turbine, long axial length and high starting wind speed, etc. , to achieve the effect of compact structure, reduced axial length and low starting wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

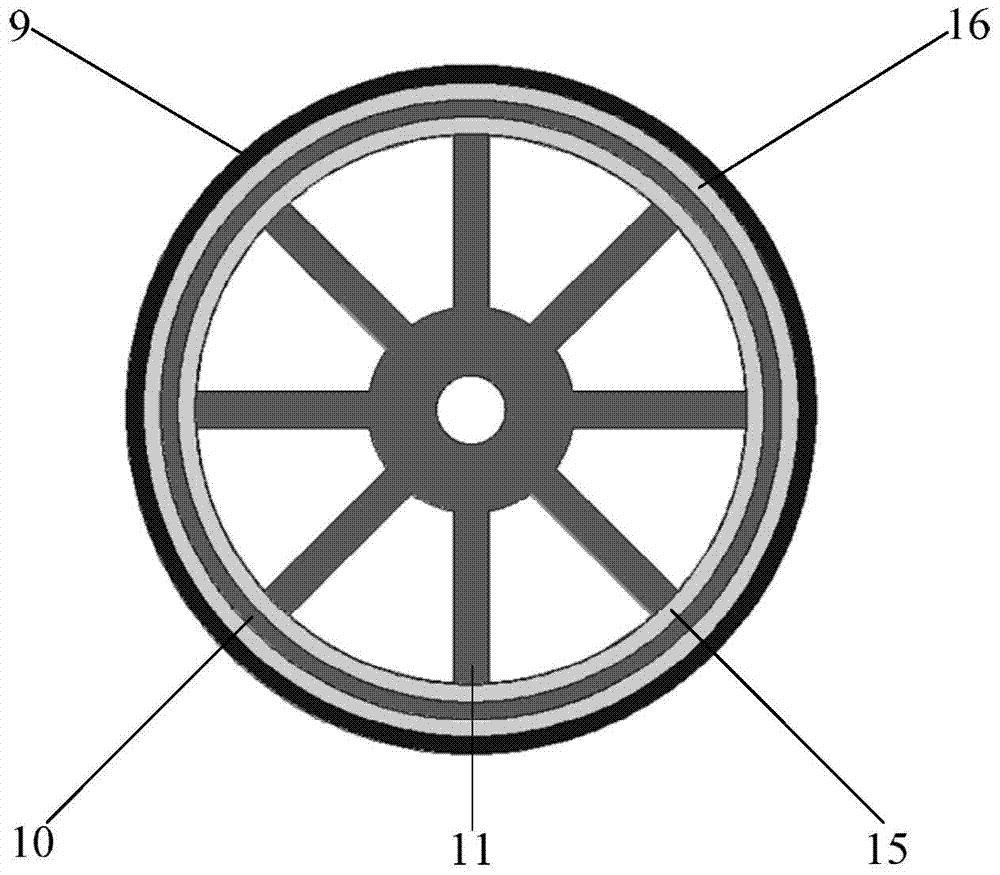

[0024] figure 1 is the overall axial sectional view of the inner rotor maglev vertical axis wind turbine, figure 2 It is the top view of the radial section of the rotor of the maglev vertical axis wind turbine. The generator stator 8 is installed on the casing 7, and forms the generator body with the generator rotor 9. The radial magnetic bearing rotor ring 10 is made of laminated silicon steel sheets, and is symmetrically fixed on the first magnetic isolation ring 15; the first radial magnetic bearing stator 6 and the second radial magnetic bearing stator 14 are respectively distributed on the rotor The upper and lower sides of the disk 11 share a radial magnetic bearing rotor ring 10, that is, the first radial magnetic bearing stator 6, the second radial magnetic bearing stator 14 and the radial magnetic bearing rotor ring 10 form the upper and lower radial magnetic be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com