Overall sea concrete filled steel tube component and application method thereof

A steel tube concrete and concrete technology, which is applied to bridge parts, underwater structures, infrastructure engineering, etc., can solve the problems of high cost of components, not in line with the national sustainable development strategy, and high cost, so as to ensure durability and work performance, alleviating the shortage of river sand supply, and the effect of solving corrosion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: All-marine steel pipe concrete member and its application

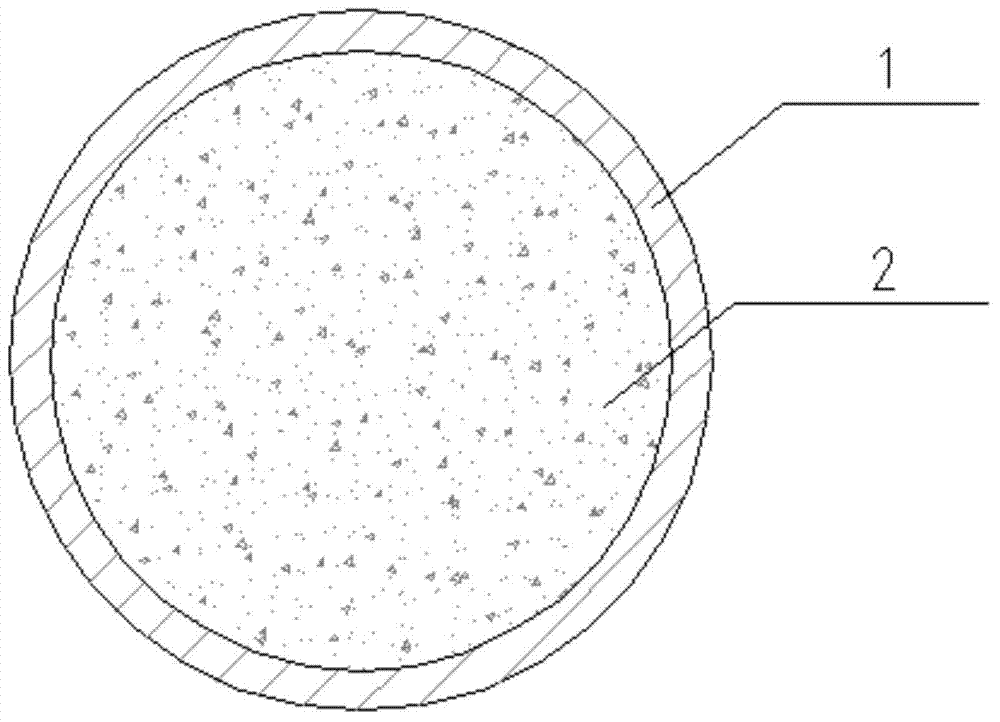

[0030] Full marine steel pipe concrete components, the specific composition is as follows figure 1 As shown, a steel tube coral concrete member includes a steel tube 1, and the steel tube is filled with concrete 2, and the concrete is composed of coral, sea sand, sea water and cement, and the coral is used as the coarse aggregate, and the sea sand is used as the fine aggregate. , forming a solid steel pipe, and the two ends of the steel pipe 1 are closed.

[0031] The application mode of the prepared full-ocean concrete-filled steel tube member: the full-ocean concrete-filled steel tube component can be used for high-rise structures (columns and piles); high-rise or super high-rise buildings (columns and piles); industrial workshops (columns); offshore platform structures support columns (columns); elevated railway or road bridges (columns and truss-rib arches).

Embodiment 2

[0032] Example 2: All-marine steel pipe concrete member and its application

[0033] Full marine steel pipe concrete components, the specific composition is as follows figure 1 As shown, a steel tube coral concrete member includes a steel tube 1, and the steel tube is filled with concrete 2, and the concrete is composed of coral, sea sand, sea water and cement, and the coral is used as the coarse aggregate, and the sea sand is used as the fine aggregate. , forming a solid steel pipe, and the two ends of the steel pipe 1 are closed.

[0034] The particle size is 50mm and the coral debris with irregular shape is used as the coarse aggregate, and coral is used to replace the sandstone in the commercially available cement. The weight ratio of coarse and fine aggregate is 50%, and the water-cement ratio is 0.5. The compression resistance of the coral concrete The strength reaches 20MPa.

[0035] The application mode of the prepared full-ocean concrete-filled steel tube member: th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com