Piston ring friction surface costing for internal combustion engine facing to bio-oil application and preparation method of piston ring friction surface costing for internal combustion engine

A friction surface and piston ring technology, which is applied to piston rings, coatings, mechanical equipment, etc., can solve the problems of corrosion, wear, shedding, failure, increased process, and poor uniformity of coating grains, so as to prevent high temperature oxidation and deterioration and improve friction Mechanical properties, the effect of eliminating residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

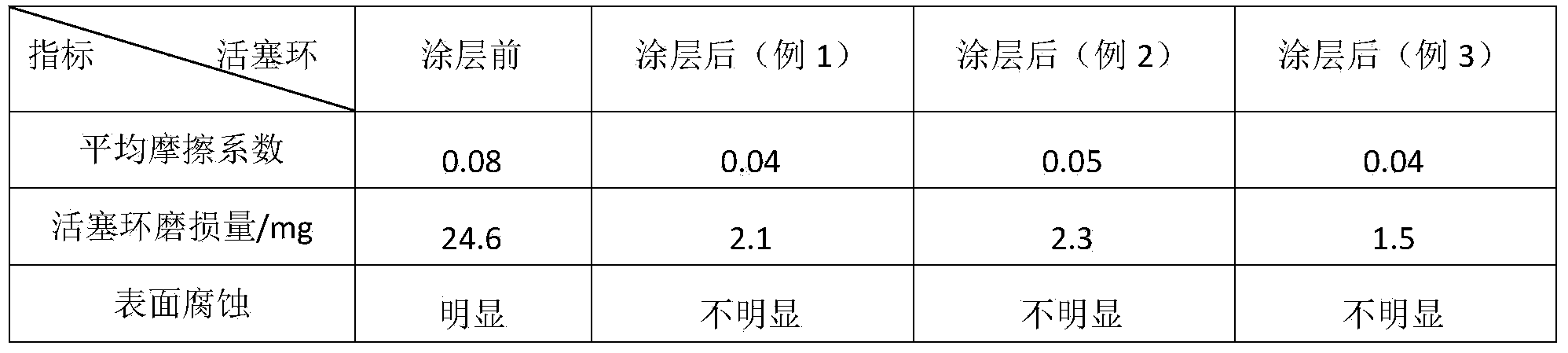

example 1

[0023] First prepare the coating solution, its composition is: NiSO 4 30g·L -1 , NaH 2 PO 2 ·H 2 O 25g·L -1 ,MoS 2 70mg·L -1 , GO 56mg·L -1 , C 4 h 6 o 5 5.5g·L -1 , EDTA-2Na 1.2mg·L -1 , OP-102.6mg·L -1 , CH 4 N 2 S 1.8mg·L -1 ; adjust the pH of the solution to 4.2, and use a water bath to heat the temperature to 84 ° C;

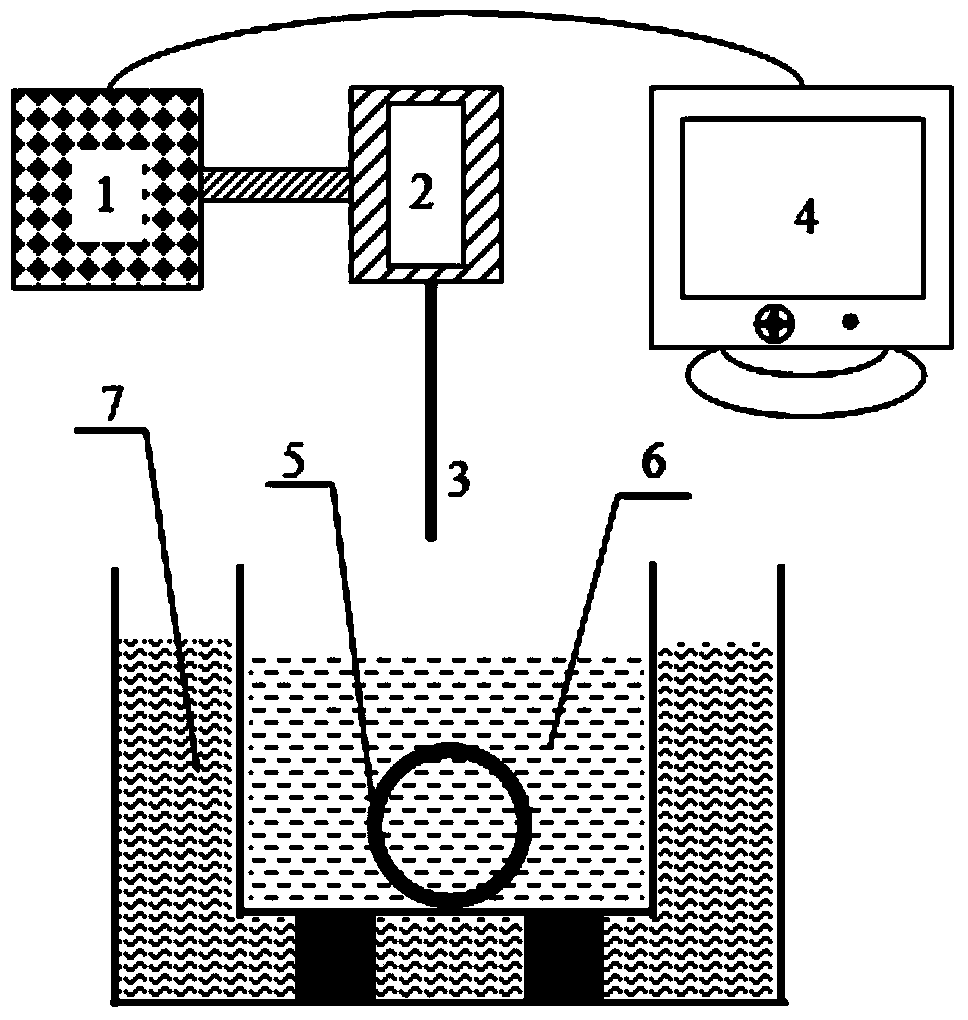

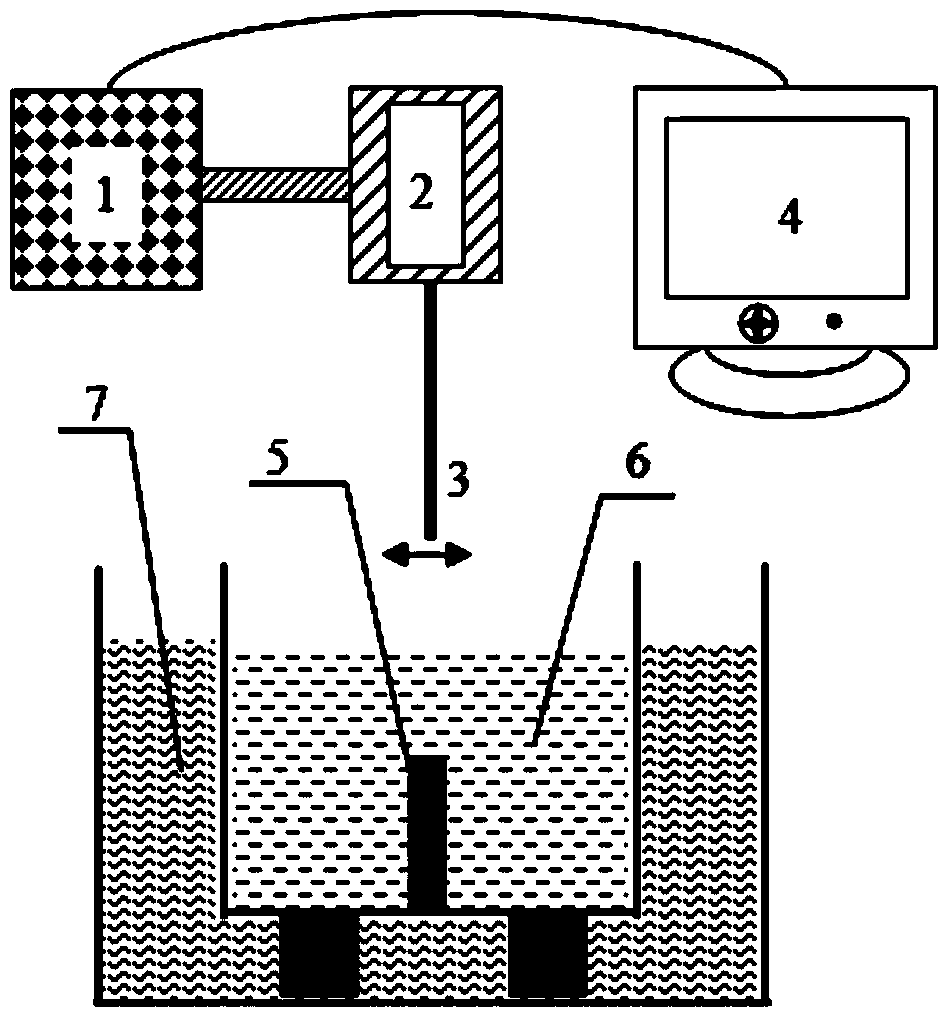

[0024] As shown in Figure 1 of the manual, adjust the distance between the liquid surface and the coating surface of the piston ring to be 5mm, the distance between the laser source and the liquid surface to be 40mm, the wavelength of the laser source to be 400nm, the power to be 5W, the spot diameter to be 20μm, and the moving speed of the light source to be 100mm / s. The path can be controlled as a straight line by connecting the laser to the software in the computer. Every time the light source moves from one side of the friction surface of the piston ring to the other, the piston ring rotates 6°. After the piston ring rotates 60 times, th...

example 2

[0028] First prepare the coating solution, its composition is: NiSO 4 35g·L -1 , NaH 2 PO 2 ·H 2 O 22g·L -1 ,MoS 2 75mg·L -1 , GO 52mg·L -1 , C 4 h 6 o 5 6.8g·L -1 , EDTA-2Na 3.6mg·L-1 , OP-104.2mg·L -1 , CH 4 N 2 S 3mg·L -1 ; Adjust the pH of the solution to 4.2, and use a water bath to heat the temperature to 86°C;

[0029] As shown in Figure 1 of the manual, adjust the distance between the liquid surface and the coating surface of the piston ring to be 8mm, the distance between the laser source and the liquid surface to be 32mm, the wavelength of the laser source to be 220nm, the power to be 6W, the spot diameter to be 20μm, and the moving speed of the light source to be 150mm / s. The path can be controlled by the laser connected to the software in the computer to be zigzag. Every time the light source moves from one side of the friction surface of the piston ring to the other side, the piston ring rotates 3°. After the piston ring has rotated 360° accumulativ...

example 3

[0033] First prepare the coating solution, its composition is: NiSO 4 32g·L -1 , NaH 2 PO 2 ·H 2 O 22g·L -1 ,MoS 2 80mg·L -1 , GO 60mg·L -1 , C 4 h 6 o 5 7.6g·L -1 , EDTA-2Na 2.4mg·L -1 , OP-103.8mg·L -1 , CH 4 N 2 S 2.2mg·L -1 ; adjust the pH of the solution to 4.2, and use a water bath to heat the temperature to 88 ° C;

[0034] As shown in Figure 1 of the manual, adjust the distance between the liquid surface and the coating surface of the piston ring to 15mm, the distance between the laser source and the liquid surface to 30mm, the wavelength of the laser source to 200nm, the power to 8W, the spot diameter to 20μm, and the moving speed of the light source to 200mm / s. The path can be controlled as a sine wave by connecting the laser to the software in the computer. Every time the light source moves from one side of the friction surface of the piston ring to the other, the piston ring rotates 9°. After the piston ring rotates 40 times, that is, the total rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com