Polymer stabilized blue phase liquid crystal composition as well as preparation method and application of liquid crystal composition

A liquid crystal composition and composition technology, applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve the problems of high material viscosity, hysteresis, high driving voltage, etc., and achieve the effect of broadening the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The method for preparing liquid crystal composition provided by the invention comprises the following steps:

[0039] First, each component can be placed in a container and mixed uniformly by heating and stirring with a magnetic stirrer, thereby preparing a mixture.

[0040] Next, heat the mixture until it is isotropic. The mixture is poured into a liquid crystal cell, and the liquid crystal cell is placed on a hot and cold table and heated to isotropy to obtain an isotropic mixture.

[0041] Afterwards, the isotropic mixture is cooled at a constant rate. Continue to place the liquid crystal cell containing the isotropic mixture on the hot and cold stage, control the cooling rate with the hot and cold stage, and cool the isotropic mixture to the blue phase temperature range T1~T2 at a uniform speed, T1 is the blue phase temperature The temperature lower limit of the zone, T2 is the temperature upper limit of the blue phase temperature zone.

[0042] Next, the cooled ...

Embodiment 1

[0045] 1) Weigh 400 mg of the compound shown in component B RM257 in component III and 400 mg of TMPEOTA in component A and place them in a container such as a penicillin vial, put a small stirring bar, heat and stir evenly on a magnetic stirrer, and make a polymer single The monomer mixture is ready for use, and the monomer mixture will serve as component III in the blue phase liquid crystal composition after subsequent photopolymerization.

[0046] 2) Weigh 930 mg of nematic liquid crystal (product number is P70-003, purchased from Shijiazhuang Chengzhi Yonghua Display Materials Co., Ltd.) and 70 mg of component I as 0.156 Δn and 33.6 ε, respectively. The resulting polymer monomer mixture is placed in a container such as a penicillin vial, and continues to weigh the chiral agent R5011 as component II Add 41.6 mg and UV photoinitiator IGRACURE 1840.5 mg into a penicillin vial, add a stirrer bar into the vial, heat and stir on a magnetic stirrer to form a mixed solution. Afte...

Embodiment 2

[0052] According to the steps of Example 1, only the consumption of A component TMPEOTA is replaced by 400 mg to 100 mg, and the consumption of nematic liquid crystal whose product number is P70-003 Δn is 0.156 and Δε is 33.6 is replaced by 930 mg to 950 mg, polymerized The amount of monomer mixture is replaced by 70 mg to 50 mg, the amount of chiral agent R5011 is replaced by 41.6 mg to 35.5 mg, the amount of ultraviolet photoinitiator IGRACURE184 is replaced by 0.5 mg to 0.3 mg, the blue phase temperature zone of the resulting mixture after cooling T1-T2 is 57-66°C. Next, carry out the constant temperature irradiation of ultraviolet light, the ultraviolet irradiation temperature T UV at 59°C, the UV irradiation energy is 0.2mw / cm 2 , the ultraviolet irradiation time is 30min, and the blue phase liquid crystal composition provided by the present invention is obtained.

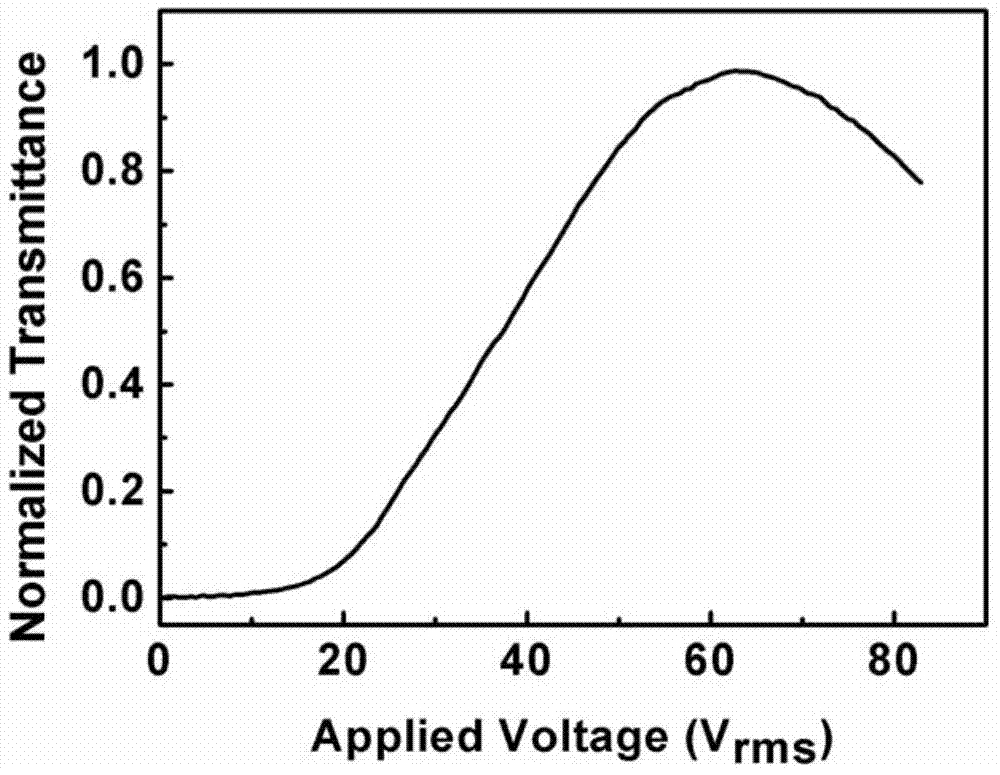

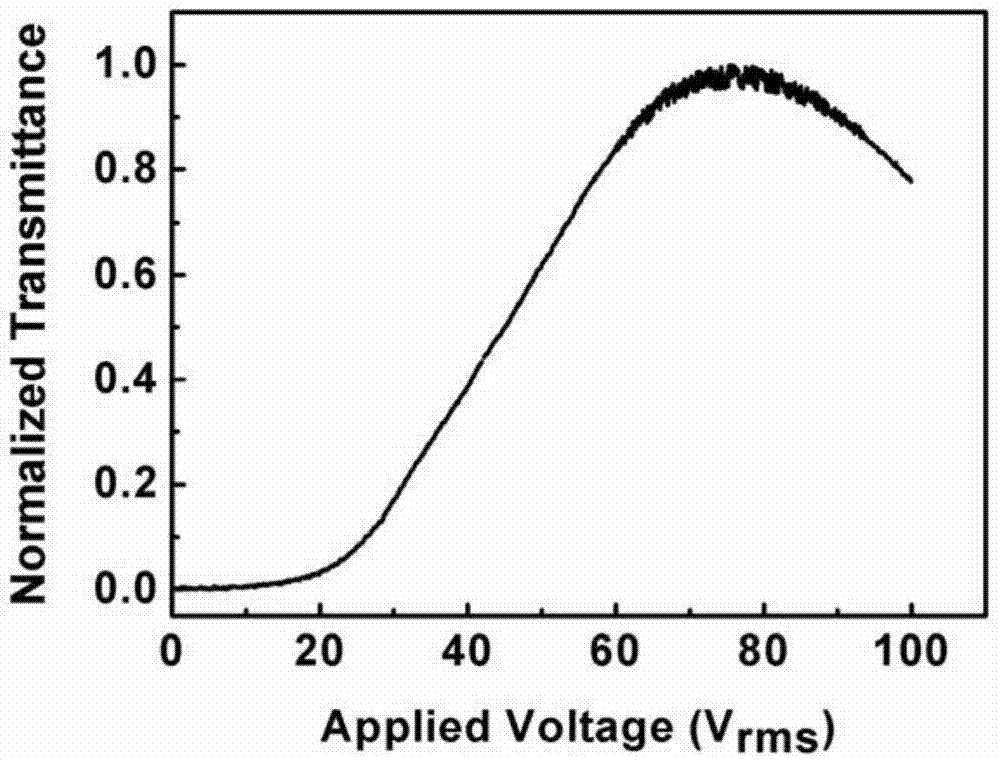

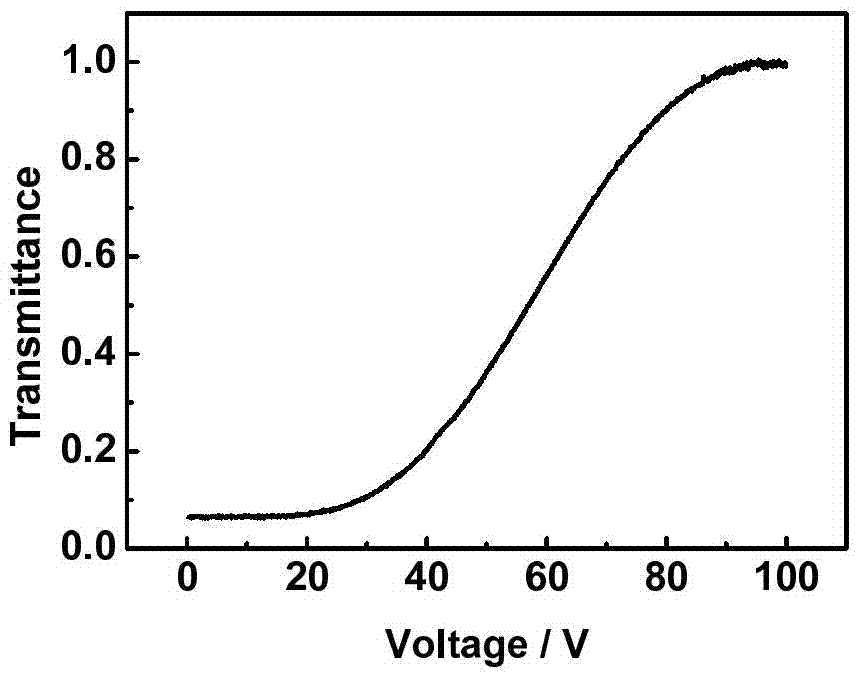

[0053] Afterwards, the blue phase temperature range T1-T2 of the blue-phase liquid crystal composition wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com