Acrylate antibacterial coating

An antibacterial coating and acrylate technology, applied in the field of coatings, can solve the problems of low temperature embrittlement, easy degradation and mildew of acrylate coatings, and achieve the effect of good and lasting antibacterial effect and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

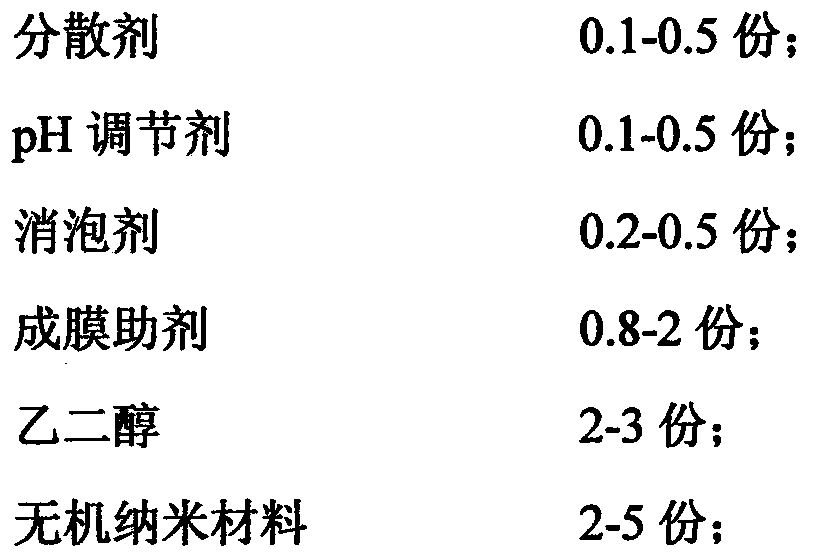

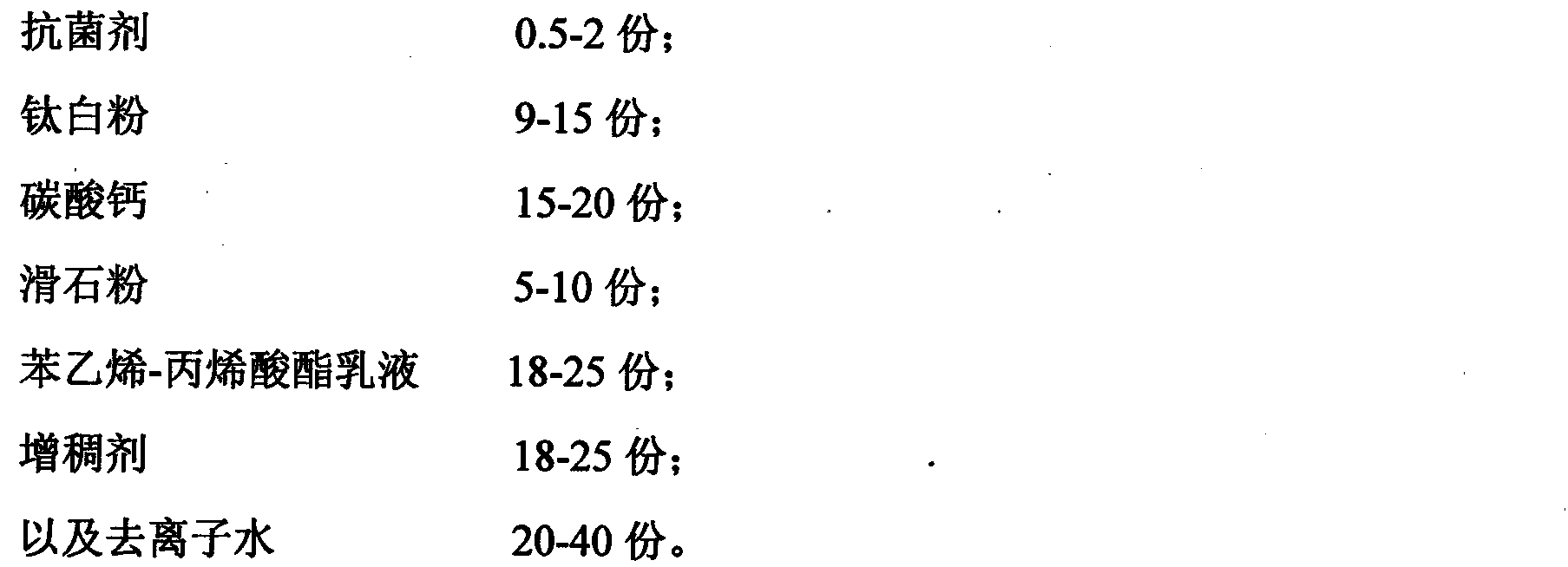

Method used

Image

Examples

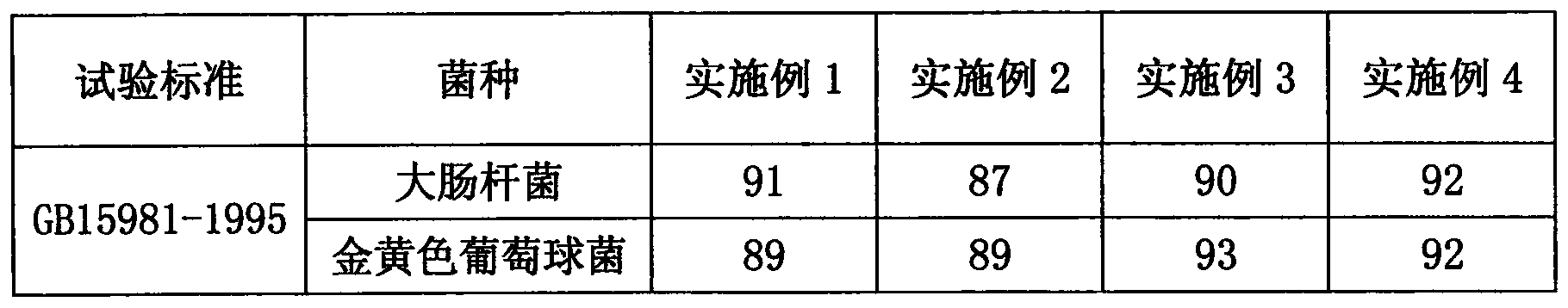

Embodiment 1

[0022] Weigh 20 parts of deionized water, add 2 parts of ethylene glycol in it, stir well and add 0.2 part of silicone defoamer, 0.8 part of film-forming aid (alcohol ester-12 coalescent) and 0.3 part of dispersant (sodium hexametaphosphate), high-speed stirring, then add 2 parts of anatase nano-TiO 2 , ultrasonic dispersion; add fillers (5 parts of talc powder; 15 parts of light calcium carbonate; 9 parts of titanium dioxide) to the above base material in sequence, and add 0.2 parts of defoamer and appropriate pH regulator to maintain the pH at about 6-7 , stir, stir the pigment slurry evenly, grind and disperse through a ball mill to obtain a pre-dispersion; add 0.3 parts of defoamer and 18 parts of styrene-acrylic emulsion to the above semi-finished coating, stir during the addition process, after the emulsion is added, Continue to add 0.5 parts of nano-TiO 2 Silver exchange body antibacterial agent, in the stirring process, add 18 parts of thickener (hydroxyethyl cellulos...

Embodiment 2

[0024] Weigh 25 parts of deionized water, add 2.5 parts of ethylene glycol to it, stir evenly, add 0.4 part of silicone defoamer, 1 part of film-forming aid (alcohol ester-12 coalescent) and 0.2 part of dispersant (sodium hexametaphosphate), high-speed stirring, then add 5 parts of anatase nano-TiO 2 , ultrasonic dispersion; add fillers (7 parts of talcum powder; 20 parts of light calcium carbonate; 10 parts of titanium dioxide) to the base material in turn, and add 0.3 parts of defoamer and appropriate pH regulator to maintain the pH at around 6-7 , stir, stir the pigment slurry evenly, grind and disperse through a ball mill to obtain a pre-dispersion; add 0.2 parts of defoamer and 22 parts of styrene-acrylic emulsion to the semi-finished coating above, stir during the addition process, after the emulsion is added, Continue to add 0.8 parts of nano-TiO 2 Silver exchange body antibacterial agent, in the stirring process, add 20 parts of thickener (hydroxyethyl cellulose), and...

Embodiment 3

[0026] Weigh 30 parts of deionized water, add 2 parts of ethylene glycol in it, stir evenly, add 0.3 parts of silicone defoamer, 1.5 parts of film-forming aid (alcohol ester-12 coalescent) and 0.5 part of dispersant (sodium hexametaphosphate), high-speed stirring, then add 4 parts of anatase nano-TiO 2 , ultrasonic dispersion; add fillers (9 parts of talc powder; 18 parts of light calcium carbonate; 13 parts of titanium dioxide) to the base material in sequence, and add 0.2 parts of defoamer and appropriate pH regulator to maintain the pH at about 6-7 , stir, stir the pigment slurry evenly, grind and disperse through a ball mill to obtain a pre-dispersion; add 0.3 parts of defoamer and 20 parts of styrene-acrylic emulsion to the semi-finished product of the coating, stir during the addition process, after the emulsion is added, Continue to add 0.8 parts of nano-TiO 2 Silver exchange body antibacterial agent, in the stirring process, add 20 parts of thickener (hydroxyethyl cel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com