Method for supercritical fluid in-situ preparation of graphene/fluoropolymer composite material

A supercritical fluid, in-situ preparation technology, applied in the field of supercritical fluid in-situ preparation of graphene/fluoropolymer composite materials, can solve the problems of difficulty in dispersion, agglomeration, easy stacking, etc., and achieves low cost, mild conditions, and low cost. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

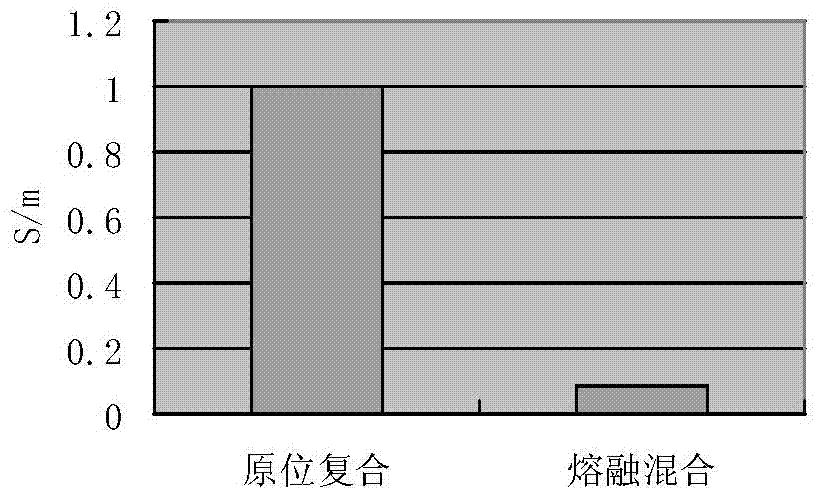

Embodiment 1

[0031] 10 parts of DMF, 1 part of natural graphite powder and 100 parts of 1,1-dihydroperfluorooctyl acrylate (FOA) were mixed ultrasonically for 5 minutes until uniform, and then added to a high-pressure mixer. Pump 300 parts of liquid supercritical carbon dioxide into a high-pressure mixer and mix evenly, then send the mixture to a high-pressure reactor. The temperature in the autoclave was increased to 31° C., the pressure was controlled between 7 and 10 MPa, and kept for 6 hours. Add 1 part of azobisisobutyronitrile (AIBN) into the autoclave, raise the temperature of the autoclave to 50° C., and control the pressure between 15 and 30 MPa. After the material stays in the autoclave for 36 hours, it is quickly sprayed into the normal pressure production tank; after the carbon dioxide and organic solvent in the production tank are removed, the final product is obtained.

Embodiment 2

[0033] Mix 5 parts of DMF, 1 part of expanded graphite powder and 200 parts of 1,1-dihydroperfluorooctyl methacrylate (FOMA), mix it with mechanical stirring for 1 hour until uniform, and then add it to the high-pressure mixer . Pump 500 parts of liquid supercritical carbon dioxide into a high-pressure mixer and mix evenly, then send the mixture to a high-pressure reactor. The temperature in the autoclave was raised to 40° C., the pressure was controlled between 8 and 10 MPa, and kept for 6 hours. Put 1 part of azobisisobutyronitrile (AIBN) into the autoclave, and heat the autoclave to 80° C., and control the pressure between 10 and 25 MPa. After the material stays in the autoclave for 48 hours, it is quickly sprayed into the normal pressure production tank. After removing the carbon dioxide and the organic solvent in the product tank, the final product is obtained.

Embodiment 3

[0035] Mix 1 part of DMF, 1 part of expanded graphite powder and 500 parts of 2-(N-methylperfluorooctylsulfonamide) ethyl acrylate (MeFOSEA) by ultrasonic mixing for 200 minutes until uniform, then add to the high-pressure mixer middle. Pump 100 parts of liquid supercritical carbon dioxide into a high-pressure mixer and mix evenly, then send the mixture to a high-pressure reactor. The temperature in the autoclave was raised to 70° C., the pressure was controlled between 30 and 40 MPa, and kept for 24 hours. Add 2 parts of azobisisobutyronitrile (AIBN) into the autoclave, heat the autoclave to 150° C., and control the pressure between 30 and 40 MPa. After the material stays in the autoclave for 36 hours, it is quickly sprayed into the normal pressure production tank. After removing the carbon dioxide and the organic solvent in the product tank, the final product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com