A high-pressure oxidation synthesis process and equipment for trihydroxymethylphosphine oxide

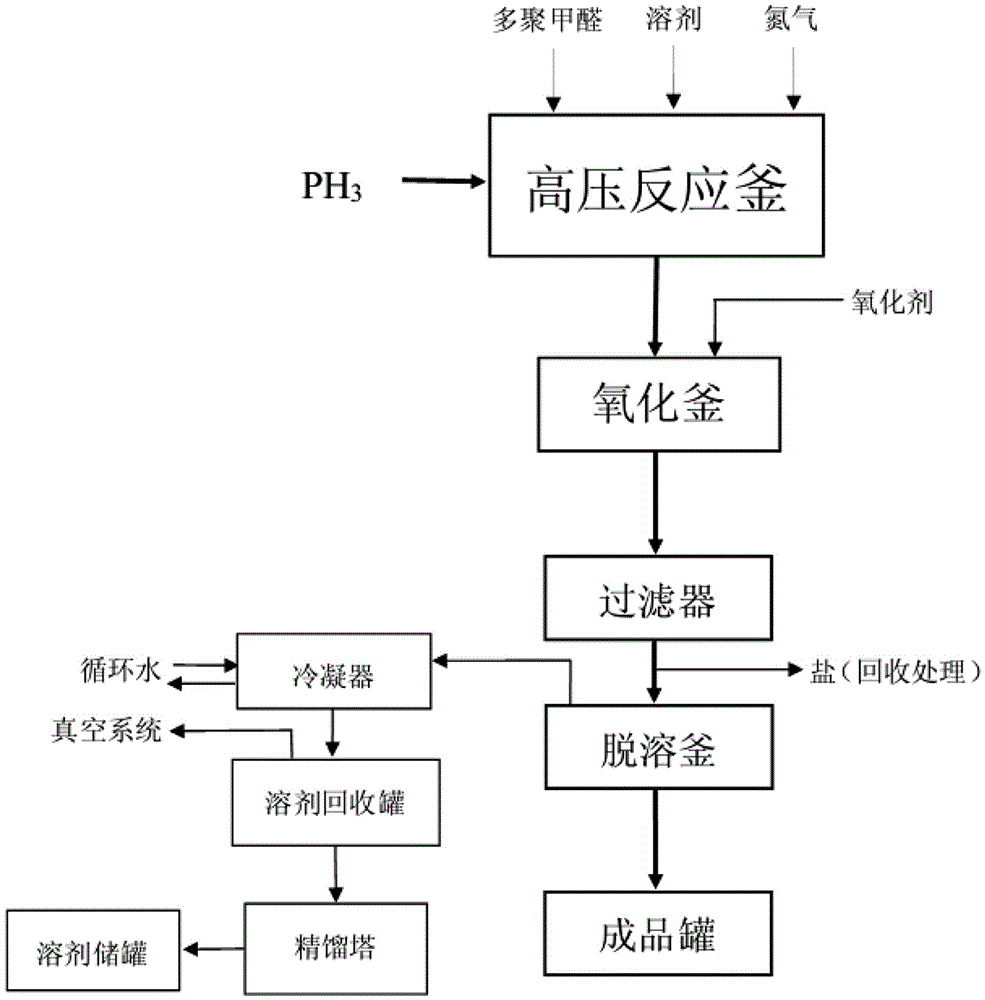

A technology of hydroxymethylphosphine oxide and synthesis process, which is applied in the field of chemical production, can solve problems such as lack of production equipment and process routes, restrict the development of industrial scale, and serious environmental pollution, and achieve great social benefits, economic value, and operational strength The effect of small size and simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add 500L methanol and 400kg paraformaldehyde into a 1000L pressure cooker, pass in nitrogen protection, stir to raise the temperature to 85°C, and pass in 160kgPH 3 Gas, pressurized to 3.5~4.0MPa, reacted for 1.5h, lowered to normal temperature and pressure; transferred the material to a 1000L oxidation kettle, 3 The throughput of / min is 28m 3 The air, heating and stirring, raised the temperature to 95 ° C, and after 5 hours of reaction, it was cooled to room temperature; the material was filtered through a filter, and the filtrate was transferred to a precipitation kettle, and the desolvation temperature was 65 ~ 70 ° C, and the solvent was dehydrated ( The solvent is rectified and recycled by the rectification tower), and when the water content of the material reaches 1.0~1.2%, the precipitation is stopped, and the material is transferred to the finished product tank. Gained THPO580Kg, the product purity is more than 99%, and the yield is more than 95%.

Embodiment 2

[0020] Add 645L ethylene glycol monoethyl ether and 322kg paraformaldehyde into a 1000L pressure cooker, pass in nitrogen protection, stir to raise the temperature to 68°C, and pass in 252kgPH 3 Gas, pressurize to 4.0MPa, react for 3h, drop to normal temperature and pressure; transfer the material to a 1000L oxidation kettle, add 32.5L peroxydicarbonate with a concentration of 80%, heat and stir, raise the temperature to 55°C, and react for 3.8 After h, it is lowered to room temperature; the material is filtered through a filter, and the filtrate is transferred to a desolventization kettle, and the desolventization temperature is 68°C, and the solvent is de-dried (the solvent is rectified and recycled by a rectification tower), and the material water When the content reaches 1.0~1.2%, stop the precipitation and transfer the material to the finished product tank. Gained THPO740Kg, product purity more than 99%, yield more than 95%.

Embodiment 3

[0022] Add 400L of methanol, 120L of dichloromethane and 400kg of paraformaldehyde into a 1000L pressure cooker, pass in nitrogen protection, stir to raise the temperature to 85°C, and pass in 160kgPH 3 Gas, pressurized to 3.5~4.0MPa, reacted for 1.5h, lowered to normal temperature and pressure; transferred the material to a 1000L oxidation kettle, 3 Influx of / min into 20m 3 Oxygen, heat and stir, heat up to 55°C, and after 5 hours of reaction, it will be cooled to room temperature; the material is filtered through a filter, the filtrate is transferred to a precipitation kettle, and vacuum distillation is carried out. The precipitation temperature is 65~70°C, and the solvent is dehydrated ( The solvent is rectified and recycled by the rectification tower), and when the water content of the material reaches 1.0~1.2%, the precipitation is stopped, and the material is transferred to the finished product tank. Gained THPO590Kg, product purity more than 98%, yield more than 95%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com