A kind of anti-bending and anti-compression nano building material and its preparation method

A building material and nanotechnology, applied in the field of building materials, can solve the problems of poor flexural and compressive properties, limited application scope, poor performance, etc., and achieve the effect of improving flexural and compressive properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

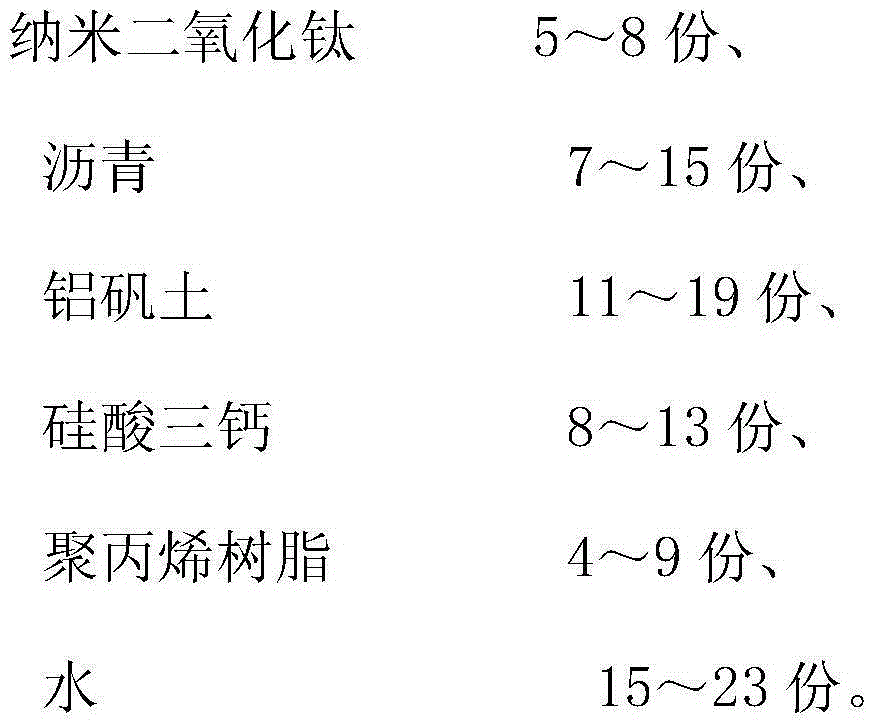

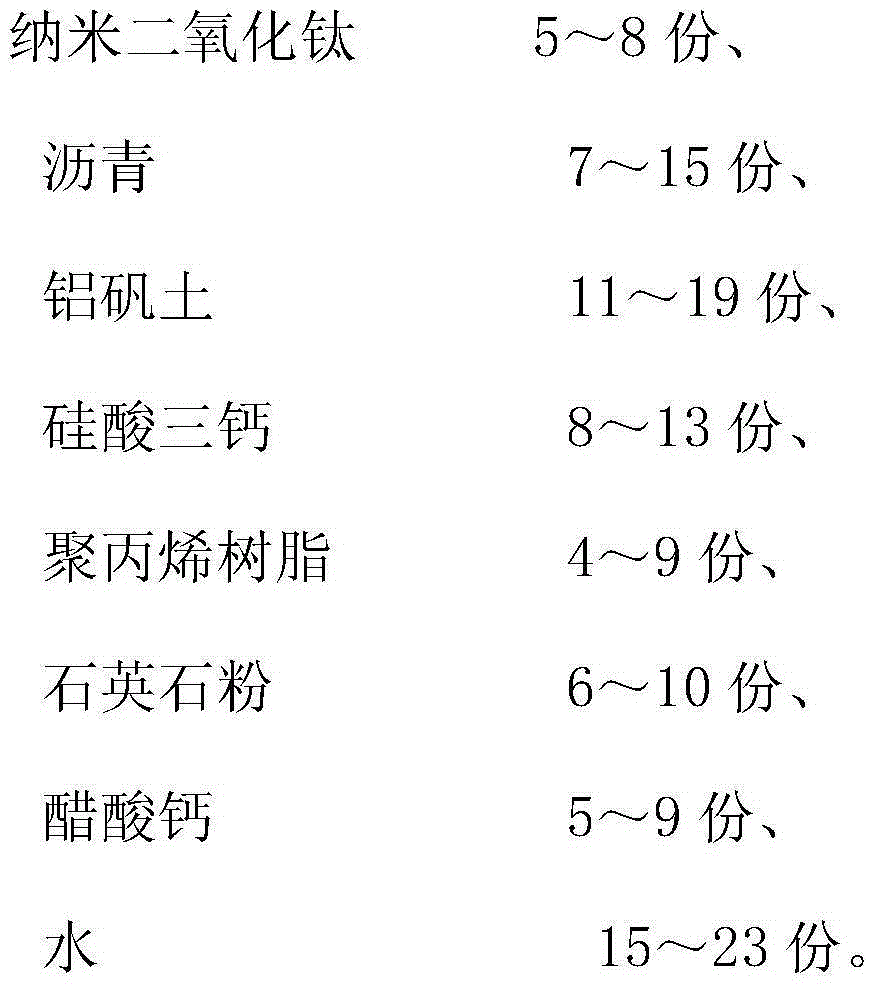

Method used

Image

Examples

Embodiment 1

[0023] (1) Grind the quartz stone into powder, the mesh number of the powder is 400 mesh, then heat the asphalt to 90°C and stir properly;

[0024] (2) 6 parts by weight of nano-titanium dioxide, 10 parts of pitch after heating, 15 parts of bauxite, 11 parts of tricalcium silicate, 7 parts of polypropylene resin, 8 parts of 400 mesh quartz stone powder, Calcium acetate is 7 parts, water is 9 parts, the above ingredients are mixed and stirred, and the mixture is formed after stirring until uniform;

[0025] (3) Inject the prepared mixed homogeneously into the forming mold, and pressurize and form;

[0026] (4) After press molding, high-temperature drying is carried out, the drying temperature is 80° C., and the drying time is 5 hours. After drying, a flexural and compressive nano-building material is prepared.

Embodiment 2

[0028] (1) Grind the quartz stone into powder, the mesh number of the powder is 400 mesh, then heat the asphalt to 90°C and stir properly;

[0029] (2) 5 parts by weight of nano titanium dioxide, 7 parts of pitch after heating, 19 parts of bauxite, 13 parts of tricalcium silicate, 9 parts of polypropylene resin, 6 parts of 400 mesh quartz stone powder, Calcium acetate is 5 parts, water is 23 parts, the above-mentioned ingredients are mixed and stirred, and the mixture is formed after stirring until uniform;

[0030] (3) Inject the prepared mixed homogeneously into the forming mold, and pressurize and form;

[0031] (4) After press molding, high-temperature drying is carried out, the drying temperature is 80° C., and the drying time is 5 hours. After drying, a flexural and compressive nano-building material is prepared.

Embodiment 3

[0033] (1) Grind the quartz stone into powder, the mesh number of the powder is 400 mesh, then heat the asphalt to 90°C and stir properly;

[0034] (2) 8 parts by weight of nano titanium dioxide, 15 parts of pitch after heating, 11 parts of bauxite, 8 parts of tricalcium silicate, 4 parts of polypropylene resin, 10 parts of 400 mesh quartz stone powder, Calcium acetate is 9 parts, water is 15 parts, the above ingredients are mixed and stirred, and the mixture is formed after stirring until uniform;

[0035] (3) Inject the prepared mixed homogeneously into the forming mold, and pressurize and form;

[0036] (4) After press molding, high-temperature drying is carried out, the drying temperature is 80° C., and the drying time is 5 hours. After drying, a flexural and compressive nano-building material is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com