Embossing printing plate for code printer and processing method thereof

A coding machine and layout technology, applied in the printing plate, printing plate preparation, printing process, etc., can solve the problems that affect the production efficiency, wear of the plate pattern, and the inability to find the layout position very accurately, so as to solve the problem of printing pressure inconsistency , Machining accuracy is improved, and the effect of eliminating plate loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

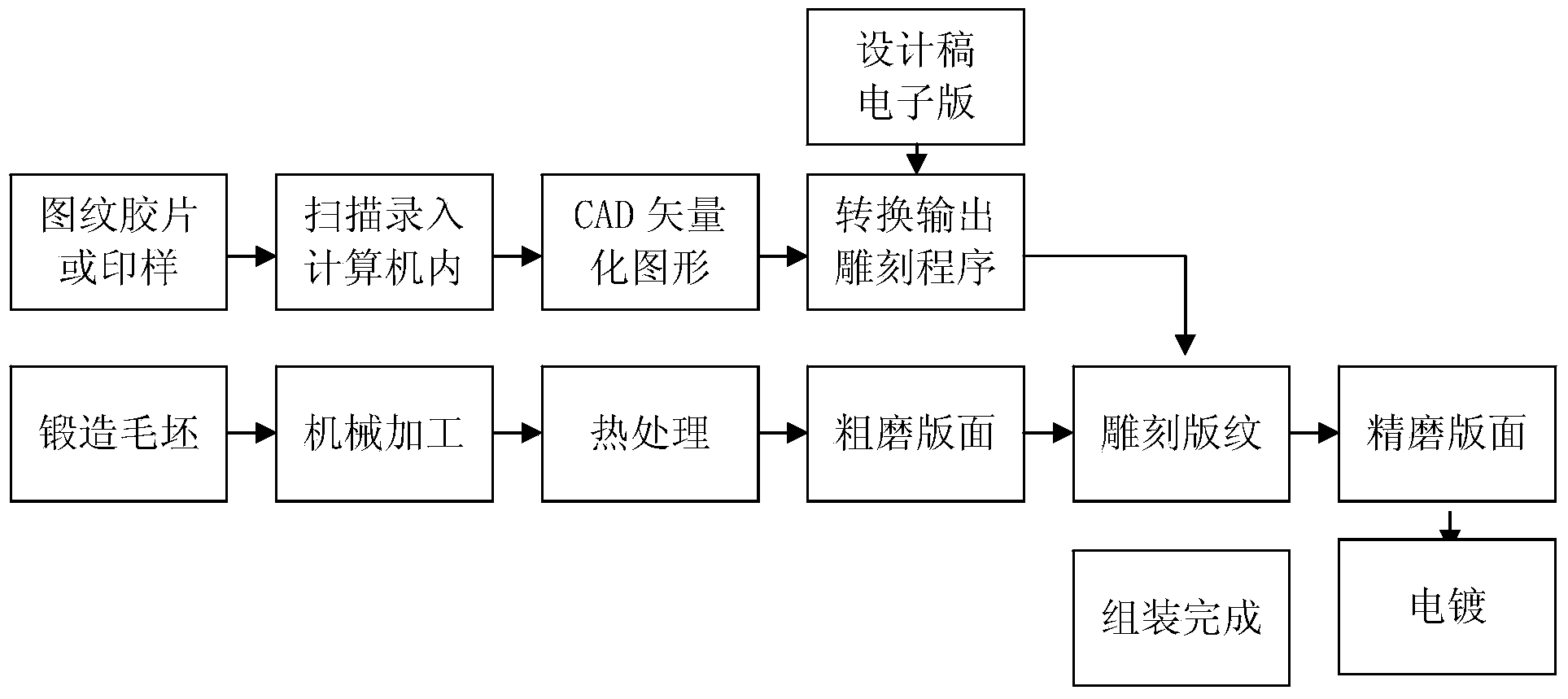

Method used

Image

Examples

Embodiment 1

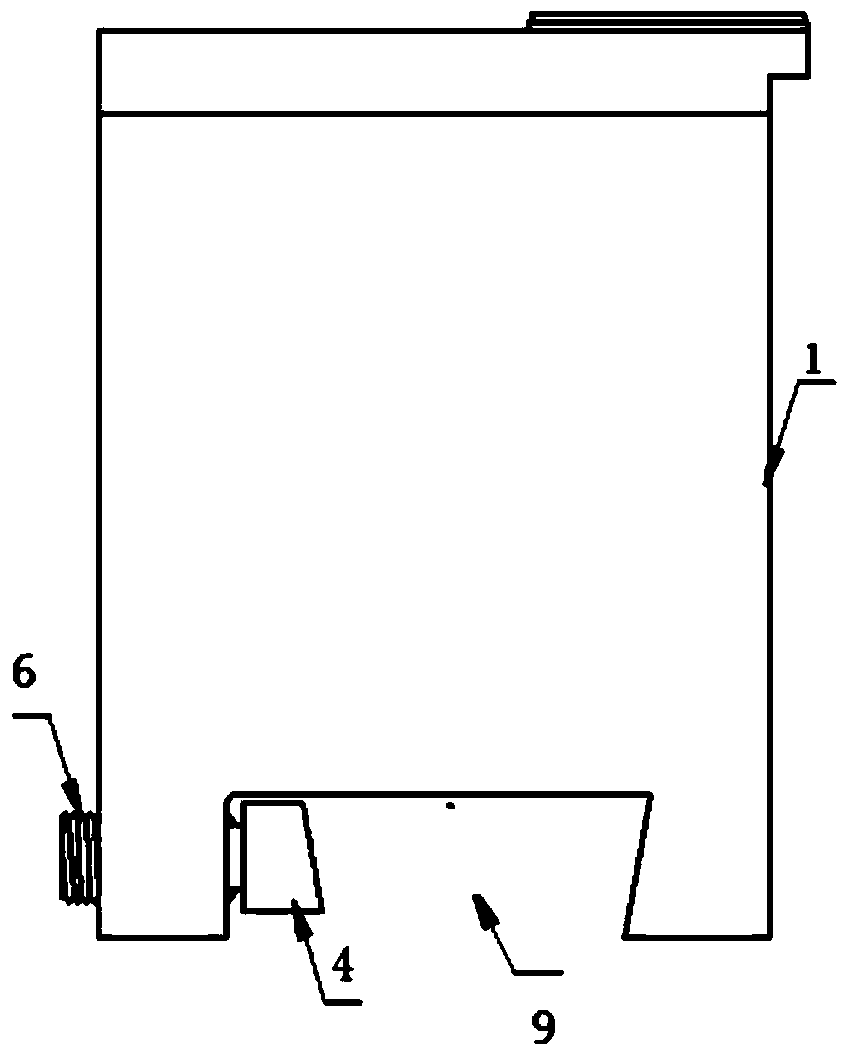

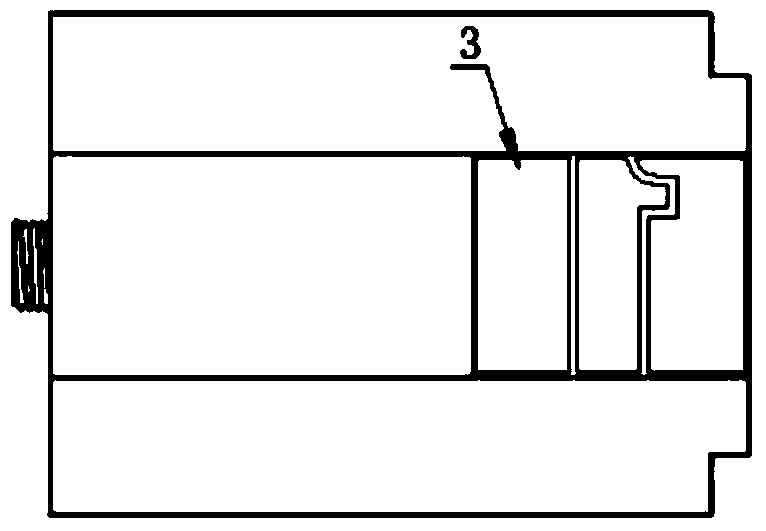

[0043] see Figure 2 ~ Figure 4 As shown, the overall structure of the relief printing plate, that is, the layout 2 and the base 1 is an integral design, which includes the layout 2 and the base 1 carrying the layout. To be installed on the printer, the arc 8 radius is 100 mm for type 300, and 137 mm for type 374. Layout 2 and base 1 are both made of 40Cr material. During the processing, the layout is heat-treated, and the base is coated with anti-seepage paint. The layout has high hardness and wear resistance, while the base has low hardness and good strength and toughness.

[0044] The inner corner of one side of the dovetail card slot 9 is a right angle, and the inner corner of the other side is an acute angle. The inner corner of the card slot is excessively rounded with a radius R of 1 mm. In addition, under the premise of not affecting the machine fluorescence and the number installation position, try to Thicken the wall thickness on both sides of the clamping, compared...

Embodiment 2

[0047] see Figure 2 ~ Figure 4As shown, the split structure relief printing plate, that is, the block 2 and the base 1 can be a split design, which includes the block 2 of the layout part and the base 1 carrying the block, and the bottom 1 of the base is provided with an arc 8 (bottom arc) and a dovetail card Groove 9 structure, in order to be installed on the printing code machine, arc radius 300 type is 100 mm, 374 type is 137 mm. The plate is made of 40Cr material, and the plate seat is made of 45 steel material. Only the plate part is heat-treated, and the plate seat part is not heat-treated. This kind of product has better manufacturability; when the machine is changing products, the plate change can be realized by changing the plate, and the plate seat does not move, so the production change is more convenient and fast.

[0048] The block height of split embossed plate is 12.5mm, and the pattern depth is >0.5mm.

Embodiment 3

[0050] The clamping structure at the dovetail slot 9 can be in two ways, see figure 2 As shown, a clamping block 4 is provided on one side of the dovetail slot, and the clamping block 4 is adjusted by a clamping screw 6 passing through the lower part of the base transversely to solve the problem of no space for side clamping. see Figure 6 As shown, the bottom of the base is provided with a clamping block 4 near the right-angle side of the dovetail slot 9, the clamping block is fixed by the clamping shaft 5, and the clamping shaft 5 is connected and fixed by the clamping screw 6 on the top of the base. This structural method can also be applied to the plate seat part of the split structure, and at the same time, it also provides an alternative method for the clamping operation of the machine.

[0051] see Figure 7-8 As shown, in order to better improve the efficiency of converting products and further reduce the cost of embossed plates, a plate wheel structure for quickly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com