HDPE (high-density polyethylene) double-wall corrugated pipe cooling device

A double-wall corrugated pipe and cooling device technology, which is applied in the processing field of HDPE double-wall corrugated pipes, can solve the problems of insufficient uniform cooling and shaping of HDPE double-wall corrugated pipes, unstable appearance and mechanical properties, and low product quality, etc. Cooling time, uniform force intensity, and the effect of increasing the cooling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

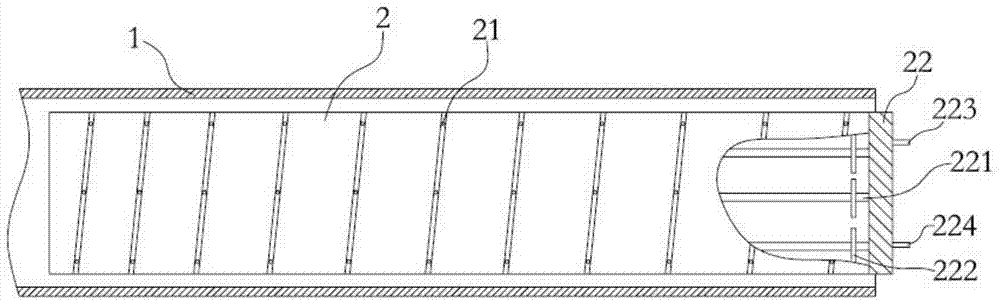

[0020] like figure 1 As shown, the present invention comprises outer body 1 and vacuum water jacket 2, and described vacuum water jacket 2 is in the inside of outer body 1, and the center line of this vacuum water jacket 2 and outer body 1 is on a straight line, and described vacuum water jacket 2 has a length of 1.2m, and a helical groove is arranged axially on the outer surface of the vacuum water jacket 2. The groove width of the helical groove is 5mm, and the groove depth is 1mm. The bottom of the tank is provided with several suction holes 21, and a section of water cavity 22 is also sleeved at one end of the feed port of the vacuum water jacket 2. The length of the water cavity 22 is 40mm, and the water cavity 22 The diameter of the vacuum water jacket 2 is consistent with that of the vacuum water jacket 2. The water cavity 22 is also horizontally provided with sever...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com