Low-temperature drilling device of resin-based fiber reinforced composite material and method thereof

A fiber-reinforced and composite material technology, applied in the field of resin-based fiber-reinforced composite material processing, can solve the problems of serious drilling, scrapped parts, high manufacturing cost of composite materials, etc., and achieve the effect of prolonging the service life and improving the quality of surface processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

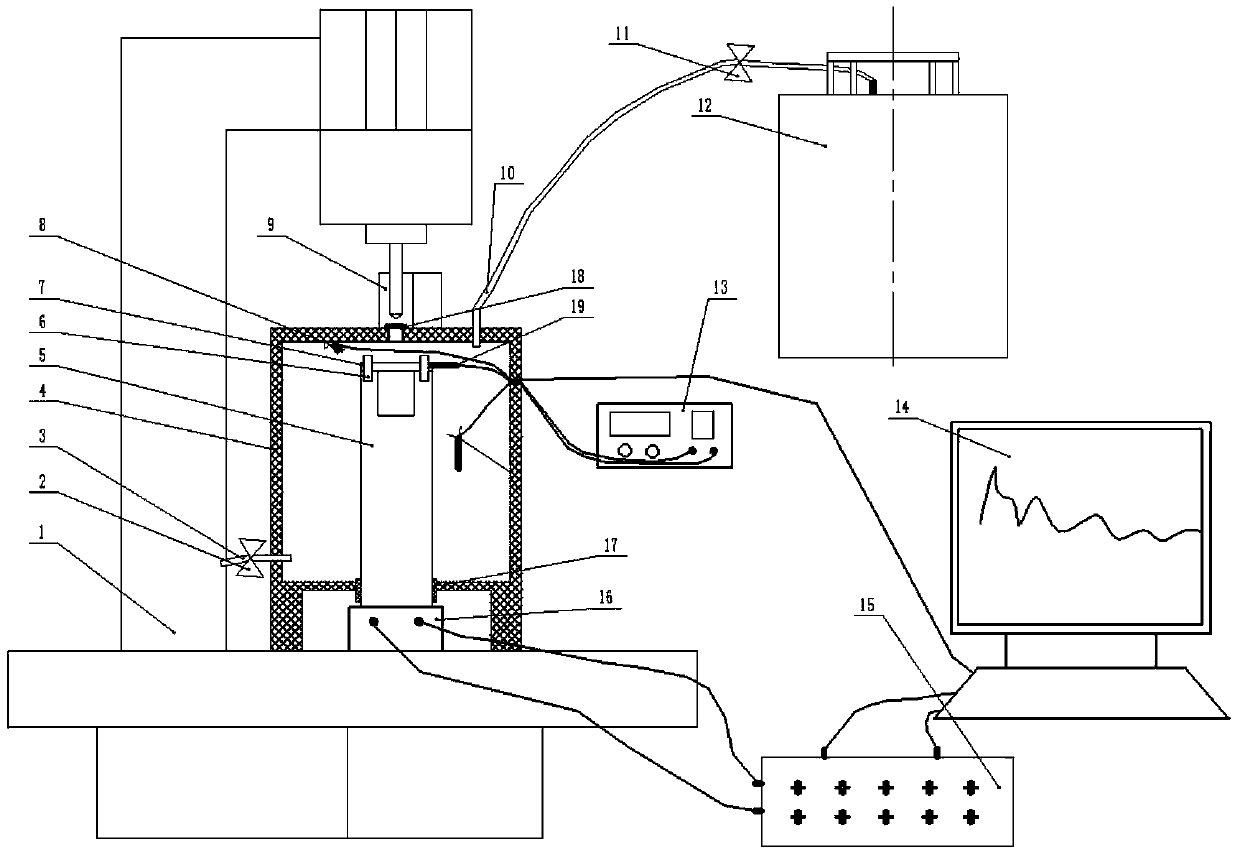

[0026] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0027] see figure 1 , the present invention is used for the low-temperature drilling processing device of resin-based fiber-reinforced composite materials, including a drilling and milling machine 1, a sealed box 4 and a cutting force measuring device fixed on the workbench of the drilling-milling machine 1, and a resin-based fiber-reinforced composite material laminate 7 Installed on the cutting force measuring device and located in the closed space in the sealed box 4; the sealed box 4 is connected with a cryogenic chamber for processing resin-based fiber reinforced composite laminates at a temperature of -80°C to 0°C A cooling device and a temperature control device; a computer 14 for recording measurement results is also connected to the cutting force measuring device. The computer 14 is also connected with a camera 8 for monitoring the machining process, the cam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com