Inner anti-oxidation argon filling protection method in welding process of pressure pipelines

A pressure pipeline and anti-oxidation technology, which is applied in the direction of welding equipment, tubular objects, arc welding equipment, etc., can solve the problems of increased construction cost, large amount of argon gas usage, and long pipeline, so as to reduce repair rate and cost, and reduce argon The effect of reducing gas consumption and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

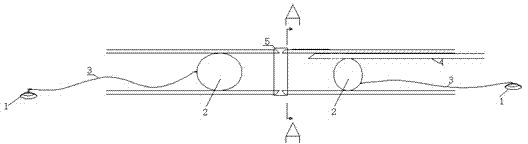

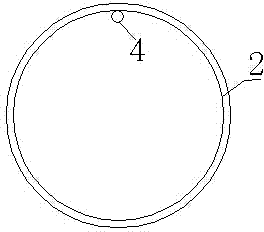

[0009] Referring to the accompanying drawings, the internal anti-oxidation and argon filling protection method for pressure pipeline welding adopts the principle of latex pressure-resistant balloon expansion. During the balloon expansion process, the pipeline is blocked to form a closed local space. The gas is released in this space to form an environment filled with inert gas. The welding joint is wrapped with high temperature resistant tape 5, and an exhaust port is left on the top of the welding joint. When the argon gas is filled, the air in the pipe can be exhausted. , and the gas concentration can be judged by igniting a match in the combustion state of the exhaust port. The specific technical scheme is: the nozzles of the two sections of the pipeline that need to be welded are aligned, and the argon gas supply pipe 4 is inserted into the two sections of the pipeline respectively. The argon air supply pipe adopts a stainless steel pipe with a diameter of 8 mm, and the arg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com