Die-casting process method for semi-solid state metal die-cast formation

一种半固态金属、压铸工艺的技术,应用在金属压铸工艺领域,能够解决气密不良、产品热变形大、内部缩孔和气孔等问题,达到确保内部结构和机械性能、形变量小、内部致密的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

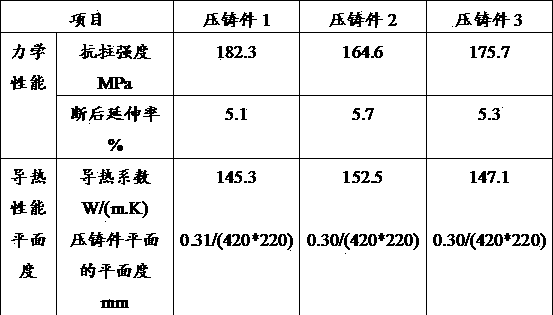

Embodiment 1

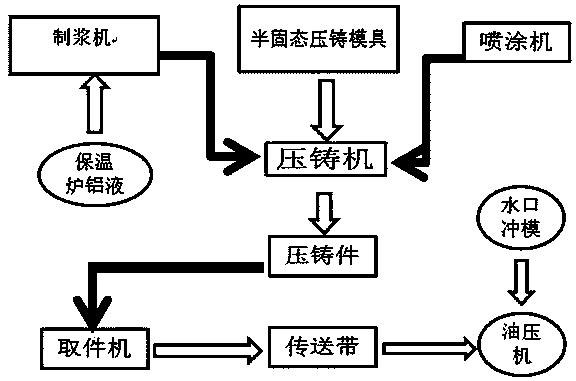

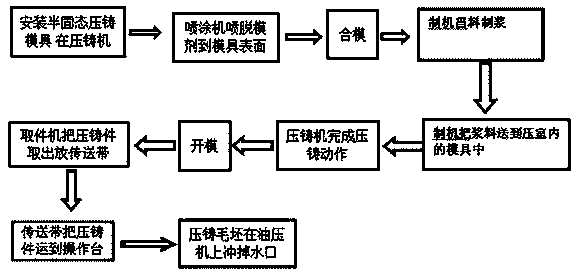

[0029] The technical solution adopted by the present invention is a die-casting process for semi-solid metal die-casting, the die-casting process uses a semi-solid die-casting machine as processing equipment, and uses a pulper as equipment for preparing semi-solid slurry and feeding materials; The equipment layout of the die-casting process described above is as follows: the left side of the semi-solid die-casting machine is a pulping machine, the right side of the semi-solid die-casting machine is a spraying machine for spraying release agent to the mold, and the front side of the semi-solid die-casting machine is a The pick-up machine is used to take out the die-casting parts in the mold. The right side of the pick-up machine cooperates with the conveyor belt. The right end of the conveyor belt is the operating table, and the operating table is equipped with a hydraulic press for flushing the upper nozzle of the die-casting parts;

[0030] The steps of the die-casting process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com