Automobile hub dust removal, spraying and drying device

A technology for drying devices and automobile wheels, which is applied in the direction of spraying devices, devices for coating liquid on the surface, coatings, etc., which can solve problems such as unstable installation, uneven spraying, and single color, so as to avoid asymmetry and uncoordination, Improve the quality of spraying and solve the effect of single color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

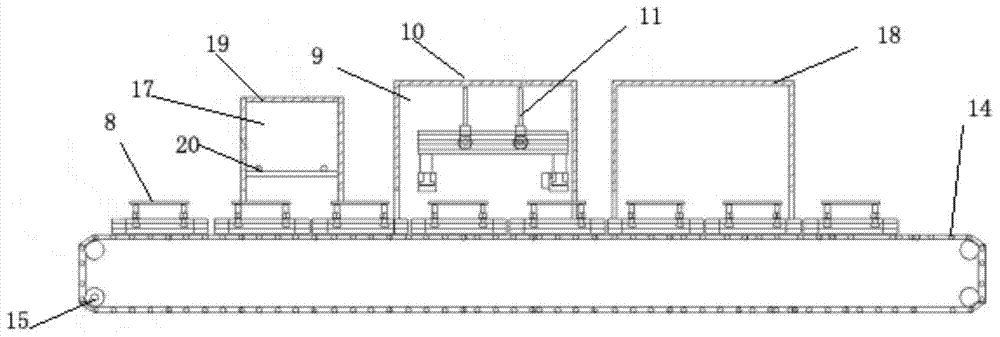

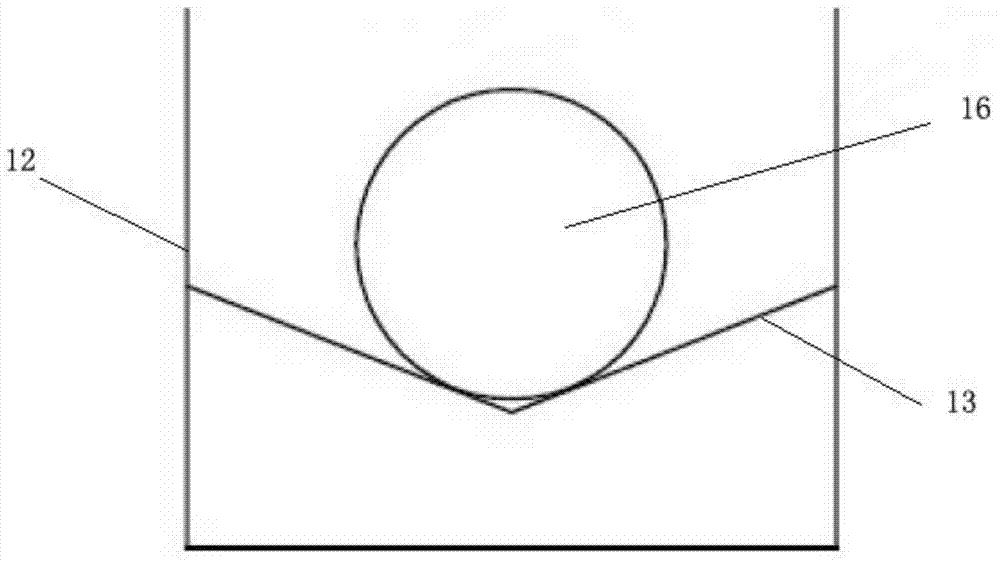

[0020] An automobile wheel dust removal spraying and drying device, including a chain transmission mechanism, a spraying bracket 8, an electrostatic dust removal device 17, a spraying machine 9 and a drying device 18, the chain transmission mechanism includes a gear disc set, and the gear disc set has four gear discs 15 , the chain 14 is arranged on the gear plate 15, the spraying bracket 8 is arranged on the chain 14, the electrostatic precipitator 17, the spraying machine 9 and the drying device 18 are successively arranged on the top of the chain transmission mechanism, and the spraying bracket 8 is successively removed from the electrostatic precipitator 17 , spraying machine 9 and drying device 18 inside.

[0021] The electrostatic precipitator 17 includes a glass cabinet 19 , and an electrostatic bar 20 for dust removal is arranged inside the glass cabinet 19 .

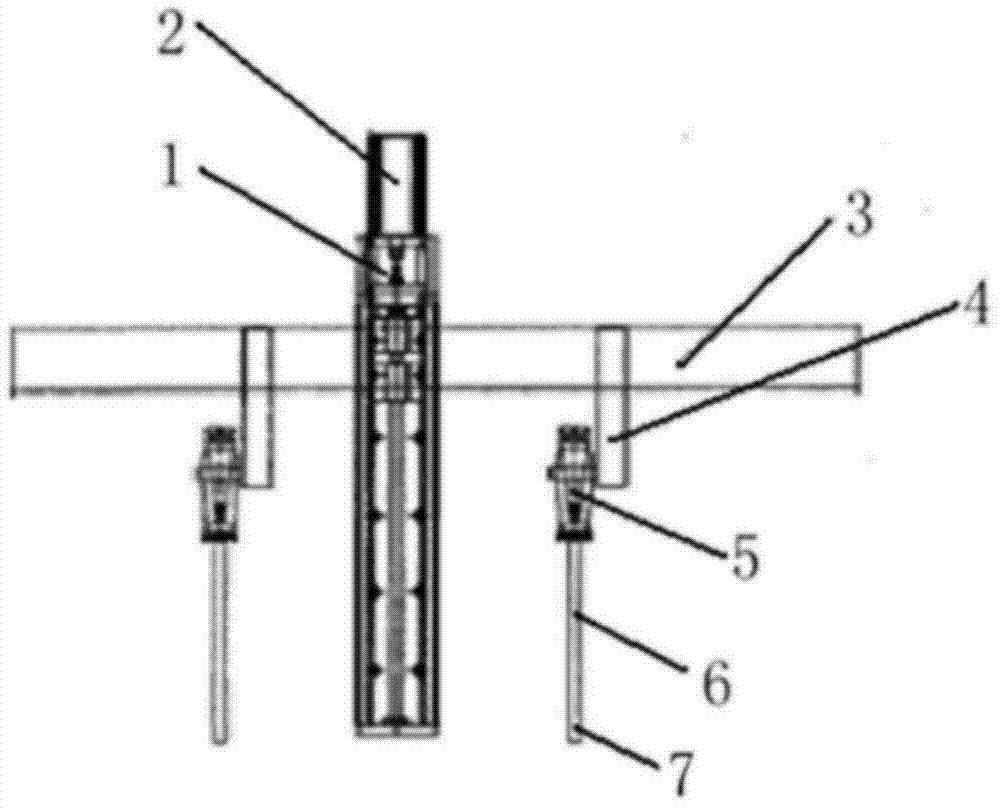

[0022] The spraying machine 9 includes a box body 10 and a spraying device 11, the spraying device 11 is arra...

Embodiment 2

[0026] An automobile wheel dust removal spraying and drying device, including a chain transmission mechanism, a spraying bracket 8, an electrostatic dust removal device 17, a spraying machine 9 and a drying device 18, the chain transmission mechanism includes a gear disc set, and the gear disc set has four gear discs 15 , the chain 14 is arranged on the gear plate 15, the spraying bracket 8 is arranged on the chain 14, the electrostatic precipitator 17, the spraying machine 9 and the drying device 18 are successively arranged on the top of the chain transmission mechanism, and the spraying bracket 8 is successively removed from the electrostatic precipitator 17 , spraying machine 9 and drying device 18 inside.

[0027] The electrostatic precipitator 17 includes a glass cabinet 19 , and an electrostatic bar 20 for dust removal is arranged inside the glass cabinet 19 .

[0028] The spraying machine 9 includes a box body 10 and a spraying device 11, the spraying device 11 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com