Paraquat emetic adding device and application thereof

A paraquat emetic and adding device technology, applied in the application, herbicides, algicides, biocides and other directions, can solve the problems of not meeting the prescribed standards, low solubility of the emetic, avoiding volatilization and degradation, and improving safety. The effect of coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

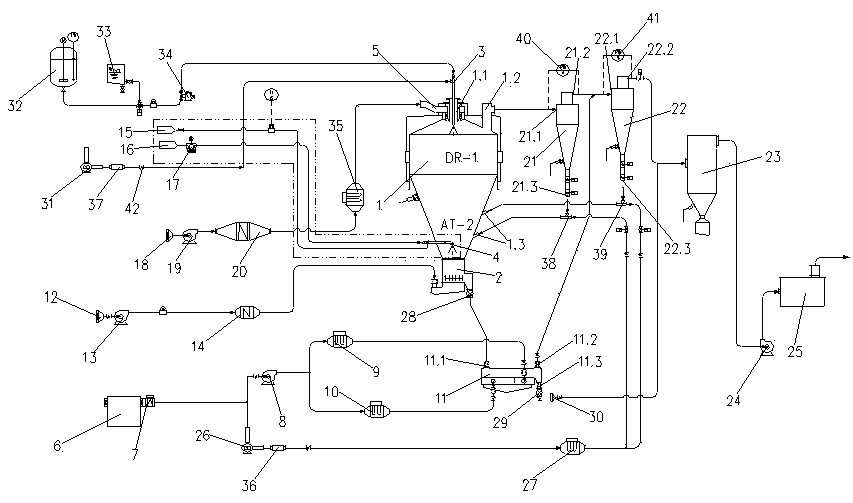

[0066] This embodiment provides a paraquat emetic addition device, such as figure 1 As shown, the emetic agent supply mechanism and the emetic agent atomization mechanism are included; the emetic agent atomization mechanism includes an emetic agent pressurized air supply structure and an emetic agent two-fluid nozzle 4, and the emetic agent pressurized air supply structure and the emetic agent The feeding mechanism is in communication with the emetic two-fluid nozzle 4, and the emetic two-fluid nozzle 4 is placed inside the lower cone of a separate drying tower 1.

[0067] The distance between the above-mentioned emetic two-fluid nozzle 4 and the bottom end of the drying tower 1 is (1 / 10, 1 / 5) of the overall height of the drying tower 1, specifically 1 / 10, 1 / 9, 1 / 8, 1 / 7, 1 / 6 or 1 / 5.

[0068] In this embodiment, the above-mentioned emetic agent pressurized air supply structure is an air compressor 15, and the air compressor 15 is in communication with the above-mentioned emetic age...

Embodiment 2

[0072] This embodiment provides a spray-drying flow granulation process of paraquat water-soluble granules using the paraquat emetic addition device provided in the first embodiment, including the following steps:

[0073] (1) Preparation of raw materials: formulating liquid mixture of preparations and emetic additives according to requirements;

[0074] (2) Spray drying and granulation: The preparation liquid mixture prepared in the above step (1) is transported to the above drying tower 1, the preparation liquid mixture is atomized into fine droplets, and the fine droplets and the drying tower 1 The hot air contact becomes a semi-dry powder; at the same time, the emetic additive liquid in the additive liquid mixing tank 16 is delivered to the emetic two-fluid nozzle 4 through the peristaltic pump 17 and compressed air delivered by the air compressor 15 It is atomized into emetic droplets under the action, and the emetic droplets are in contact with the semi-dry powder falling fro...

Embodiment 3

[0085] This embodiment provides a paraquat water-soluble granule spray drying flow granulating device using the paraquat emetic addition device in the first embodiment, and the paraquat water soluble granule spray drying flow granulating device can be applied to the second embodiment Paraquat water-soluble granules spray drying flow granulation process, and in addition to the paraquat emetic addition device of the first embodiment, it also includes a feeding mechanism, an atomizing mechanism, an air inlet mechanism, a drying granulation mechanism, Vibration fluidized drying and cooling mechanism and exhaust mechanism.

[0086] Such as figure 1 As shown, the above-mentioned drying and granulation mechanism includes a granulation and air supply structure connected to a drying tower; the top of the drying tower 1 is provided with a first input port 1.1 and a first output port 1.2, and a second input port 1.3 is provided at the bottom of the drying tower 1, and A built-in fluidized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com