Composite manganese smelting furnace charge preparation process capable of realizing comprehensive utilization of manganese ore

A preparation process and manganese furnace technology are applied in the field of preparation technology of compound manganese smelting charge, which can solve the problems of unsatisfactory sintering strength, poor spheroidization of fine-grained manganese ore powder, affecting the service life of equipment, etc., so as to improve the vertical sintering speed. and utilization coefficient, overcome the poor air permeability of the material layer, and save consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

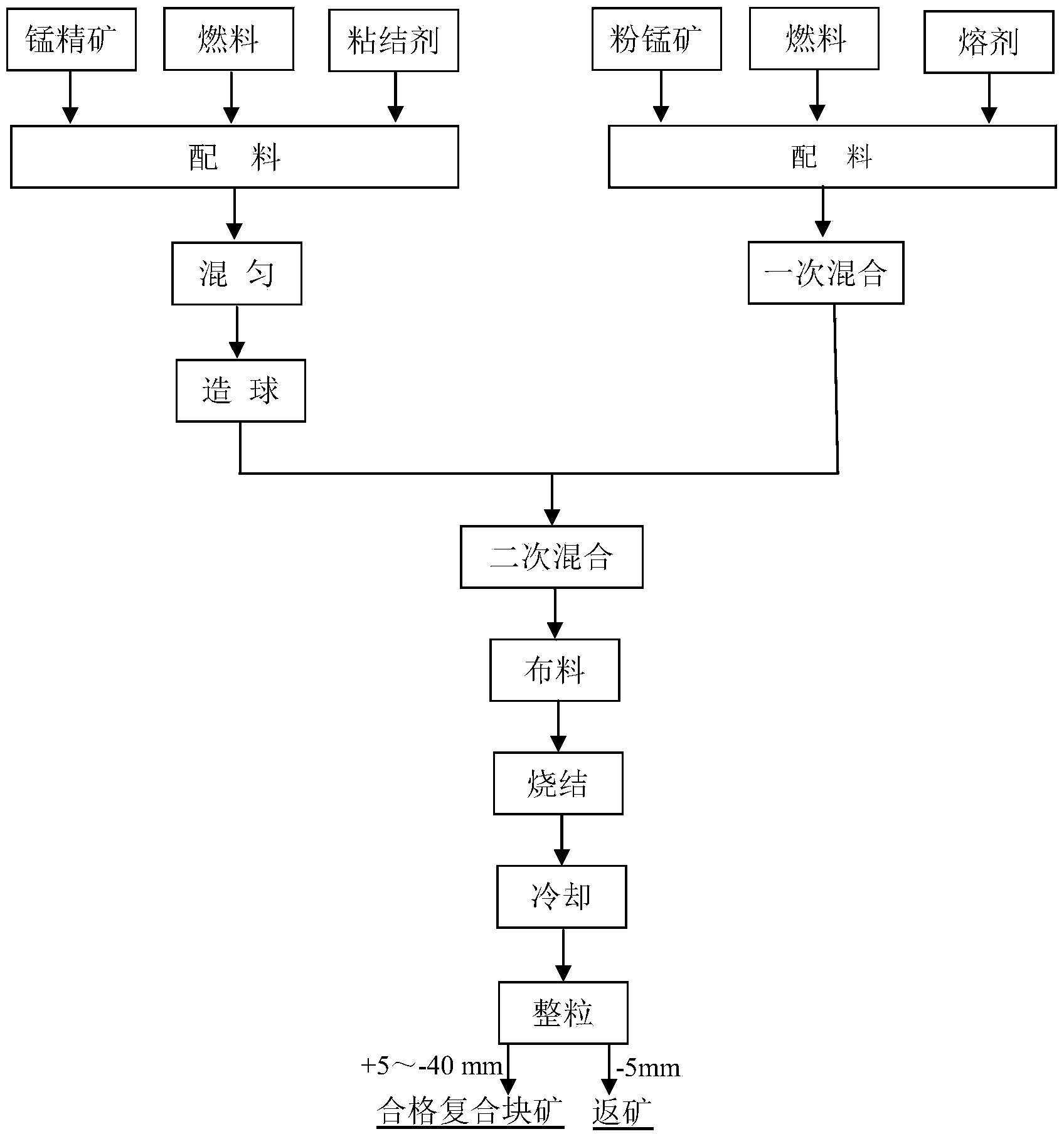

[0028] a kind of like figure 1 The compound manganese smelting charge preparation process that can realize the comprehensive utilization of manganese ore of the present invention comprises the following steps:

[0029] 1) Preparation of pellets: mix a fine-grained manganese concentrate (raw ore particle size is -0.074mm 85.3%), binder and fuel with water, and make the mixed mixture A into pellets on the pelletizer Group material; bentonite is selected as the binder, and its dosage is 1.2% of the mass of fine-grained manganese concentrate; coke powder is selected as fuel, and the particle size of coke powder is less than 3mm, and the dosage of coke powder is 2.5% of the mass of fine-grained manganese concentrate ;The water content of the pellets is 9.5%; the pelletizing time is controlled at 13 minutes, the drop strength of the green pellets after pelletizing is 5.6 times / 0.5m, the compressive strength is 12.4N / piece, and the bursting temperature is 385°C;

[0030] 2) Preparat...

Embodiment 2

[0034] A kind of composite manganese smelting charge preparation process that can realize the comprehensive utilization of manganese ore of the present invention comprises the following steps:

[0035]1) Preparation of pellets: mix a fine-grained manganese concentrate (raw ore particle size is -0.074mm 83.5%), binder and fuel with water, and make the mixed mixture A into balls on the pelletizer Agglomerate material; bentonite is selected as the binder, and its dosage is 1.5% of the mass of fine-grained manganese concentrate; coke powder is used as fuel, the particle size of which is less than 3mm, and the dosage of coke powder is 2.5% of the mass of fine-grained manganese concentrate ;The water content of the pellets is 8.5%; the pelletizing time is controlled at 13min, the drop strength of green pellets after pelletizing is 4.8 times / 0.5m, the compressive strength is 11.47N / piece, and the bursting temperature is 415°C;

[0036] 2) Preparation of Mixture B: Separately take fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com