Insulating refractory plate

A fire-resistant board and insulating layer technology, which is applied to fire protection, synthetic resin layered products, building components, etc., can solve the problems of troublesome processing of fire-resistant boards and difficult quality assurance, and achieve the effect of overall lightness, strong elasticity, and overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

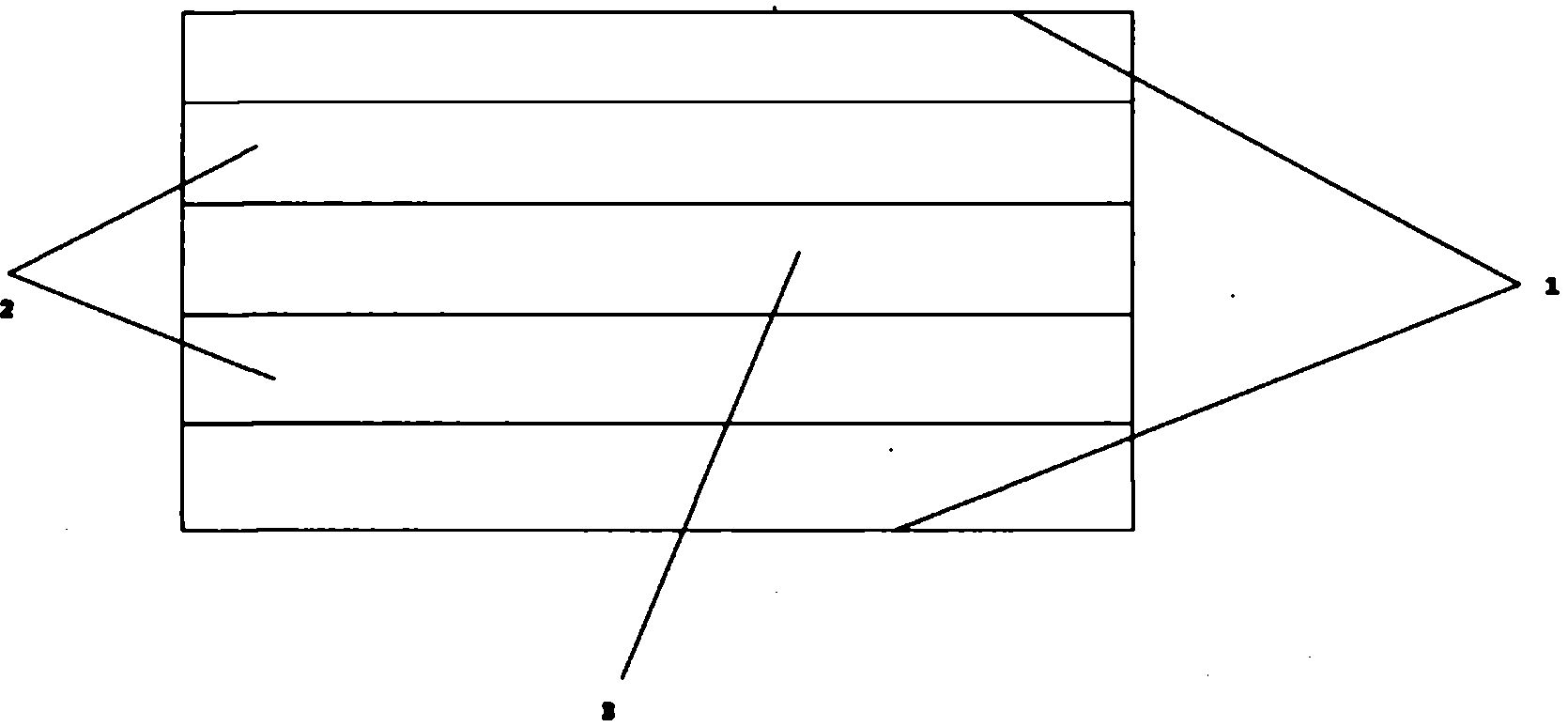

[0010] The specific embodiments of the present invention are as follows: an insulating fire-resistant board, including a fire-resistant layer 1, an insulating layer 2 and a foam layer 3, the foam layer 3 is in the middle; the insulating layer 2 is on both sides of the foam layer 3; the fire-resistant Layer 1 is on both sides of insulating layer 2. Use a hook knife (or the back of the wallpaper knife) to cut out an insulating fire-resistant board that is slightly larger than the required size, then brush the tempered glue on the insulating fire-resistant board and the place that needs to be pasted, and let it dry until it does not stick to your hands (5-15 minutes) Paste it with pressure or hit it with a hammer (it needs to be placed on a flat plate) without bubbles, and then use a file (for iron) to cut off the excess.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com