Board-like cork material and method for producing same

A manufacturing method and cork technology, applied in chemical instruments and methods, papermaking, textiles and papermaking, etc., can solve environmental problems, reduce visual aesthetics, increase the cost of coating cork and other problems, achieve blocking cement poisoning and air conditioning, price Affordable and fuel saving effect for heating and cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

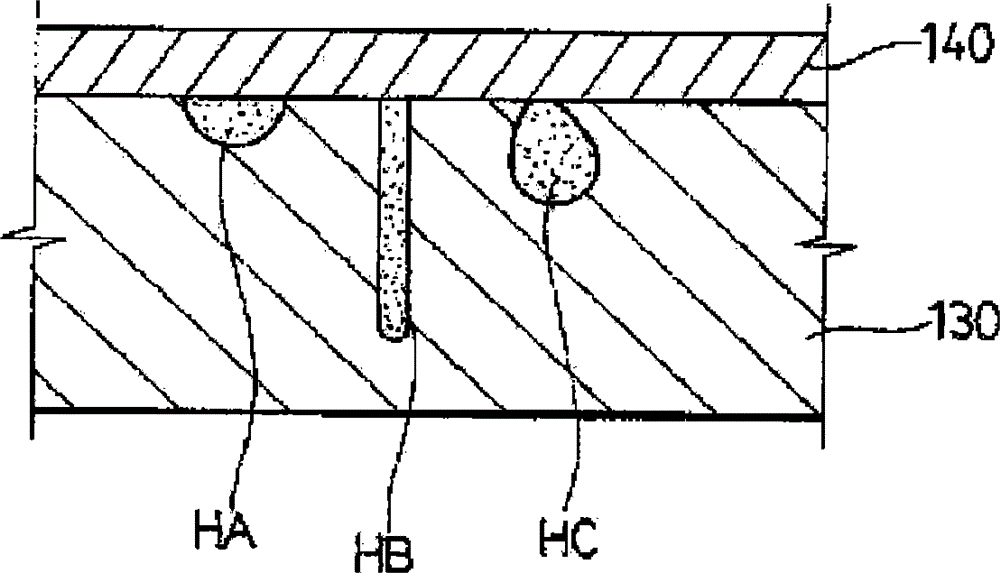

[0036] The term "metaphysical grooves" used in the present invention is understood to include cork particles and fine deformed grooves between particles as well as ultra-fine microporous grooves of the cork surface itself formed by porous cells.

[0037] Hereinafter, the present invention will be described in more detail with reference to the drawings.

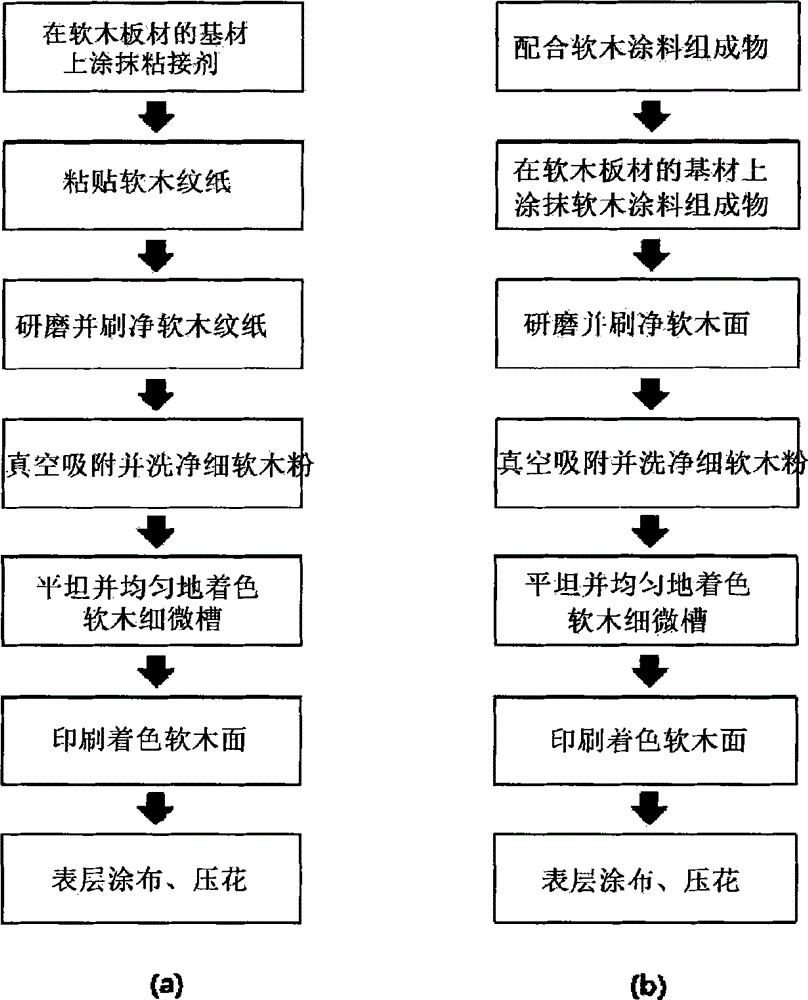

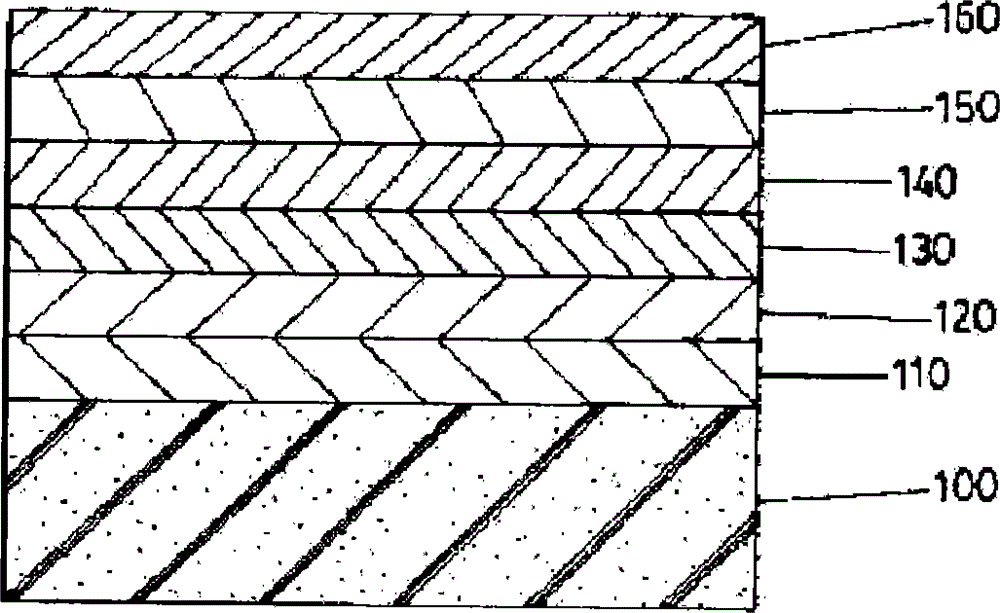

[0038] figure 1 is an engineering drawing showing the manufacturing method of the present invention, figure 2 is a cross-sectional view showing a cork board made according to an embodiment of the present invention, image 3 It is a figure showing the situation when the coloring composition is applied to the cork grain paper layer by omitting the air vacuum adsorption process and the cleaning process as in the present invention, Figure 4 It is a figure showing the situation when the compression impregnation process as in the present invention is omitted and the coloring composition is applied to the cork grain paper layer, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com