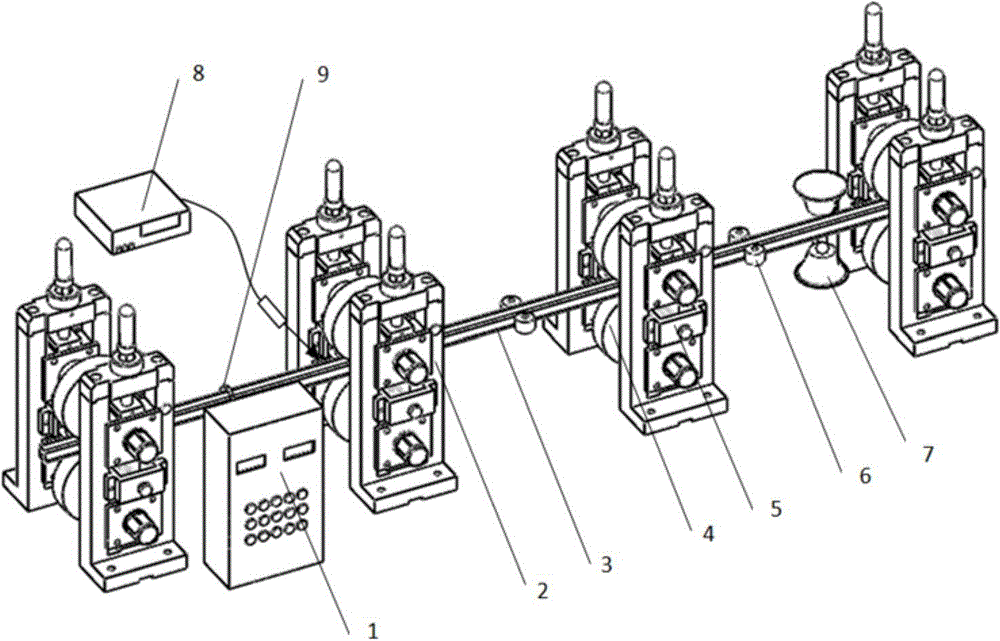

Method and device for forming ultra-high-strength precision rectangular tube

An ultra-high-strength, forming method technology, applied in the field of local heating roll bending, can solve the problem of inability to produce ultra-high-strength precision rectangular tubes, and achieve the effects of ensuring strength, reducing straightening tension and fast forming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

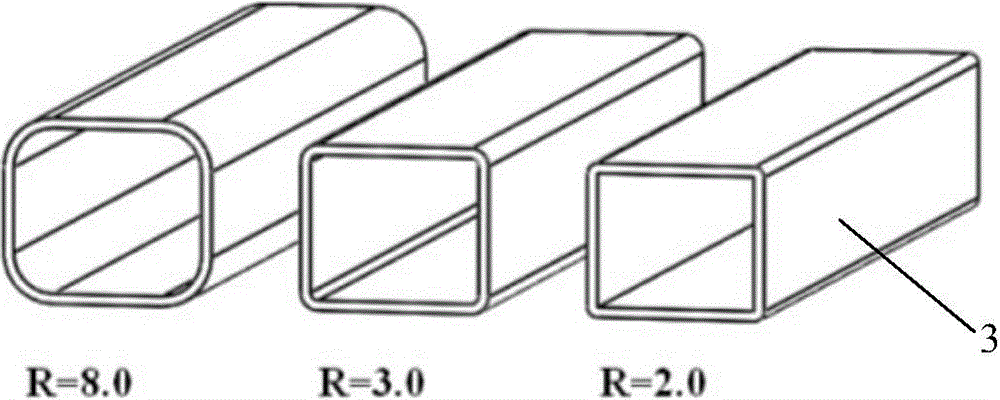

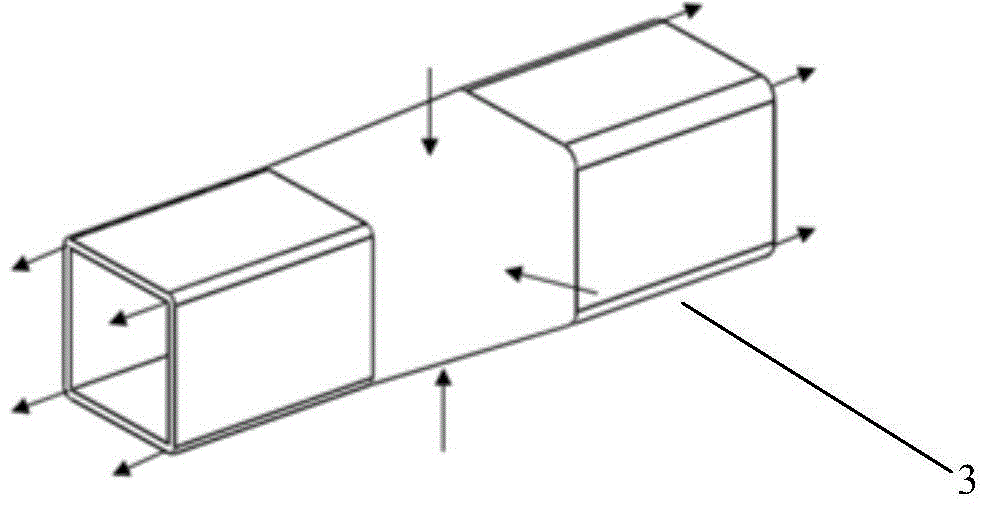

[0048] 1) Pre-bend the ultra-high-strength steel plate into a preformed rectangular tube with a fillet radius R=8, with a size of 40.0×40.0×2.0mm; 2) Rapidly heat the fillet of the preformed rectangular tube at a feed rate of 10m / min to 600°C; 3) After hot extrusion, finishing and straightening, a precision rectangular tube with a size of 38.5×38.5×2.0mm, a fillet radius R=4.0 and a dimensional accuracy of 0.1mm is obtained. After quality testing, the precision rectangular tube has less work hardening phenomenon, less residual stress and improved elongation.

Embodiment 2

[0050]1) Pre-bend the ultra-high-strength steel plate into a preformed rectangular tube with a fillet radius R=8, with a size of 40.0×40.0×2.0mm; 2) Rapidly heat the fillet of the preformed rectangular tube at a feed rate of 15m / min to 650°C; 3) After hot extrusion, finishing and straightening, a precision rectangular tube with a size of 38.0×38.0×2.0mm, a fillet radius R=2.0 and a dimensional accuracy of 0.1mm is obtained. After quality testing, the precision rectangular tube has less work hardening phenomenon, less residual stress and improved elongation.

[0051] The beneficial effects of above-mentioned technical scheme of the present invention are as follows:

[0052] (1) Compared with the traditional roll forming process, the hot roll forming technology of the present invention focuses on the application of high-strength steel or ultra-high-strength steel, and has obvious technical advantages and a wide range of applications; compared with hot stamping , The hot roll fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com