Retained austenite contained dual phase steel color metallography coloring agent and coloring display method

A technology of residual austenite and color metallography, which is applied in the direction of color/spectral characteristic measurement, measuring device, material analysis through optical means, etc. Organizations cannot accurately distinguish and identify problems, to achieve the effect of improving accurate analysis, easy identification, and clear outline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

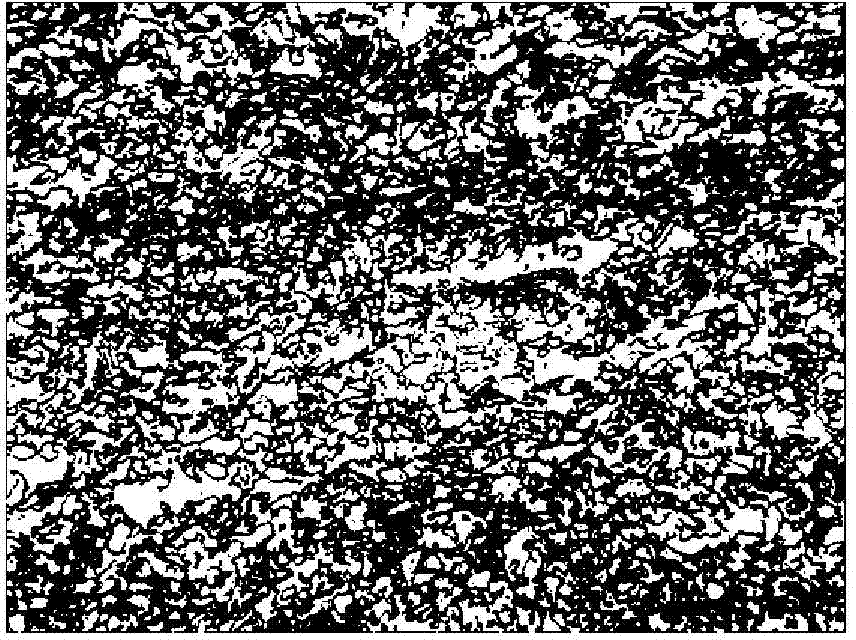

Image

Examples

Embodiment 1

[0043] (1) sodium metabisulfite and water are mixed with the aqueous solution A that is 1% concentration by mass percent;

[0044] (2) Picric acid and alcohol are configured into alcohol solution B with a mass percentage of 4% concentration;

[0045] (3) Prepare the etching solution: take 25ml of 1% aqueous solution A and 4% alcohol solution B respectively, mix them according to the volume ratio of 1:1, and add 0.2ml of concentrated hydrochloric acid with a concentration of 38%. well mixed.

[0046] (4) Put the metallographic sample 3# (annealing temperature Ta=800°C) of dual-phase steel with a length of 20mm×width 15mm×thickness 1.5mm into the above-mentioned etching solution, the immersion time is 3s, and the immersion depth is 8- 15mm, take out the sample after the surface turns light blue, and control the etching temperature at 20-30°C. Rinse the etched sample with a large amount of water first, then sprinkle it with alcohol, and after fully removing the water, use electr...

Embodiment 2

[0050] (1) sodium metabisulfite and water are mixed with the aqueous solution A that is 10% concentration by mass percent;

[0051] (2) Picric acid and alcohol are configured into alcohol solution B with a mass percentage of 4% concentration;

[0052] (3) Prepare the etching solution: Take 25ml of 10% aqueous solution A and 4% alcohol solution B, mix them according to the volume ratio of 1:1, and add 1ml of concentrated hydrochloric acid with a concentration of 38%, mix uniform.

[0053] (4) Put metallographic sample 3# (annealing temperature Ta=800°C) of duplex steel with length 20mm×width 15mm×thickness 1.5mm into the above-mentioned etching solution, immersion time is 10s, immersion depth is 8- 15mm, take out the sample after the surface turns light blue, and control the etching temperature at 20-30°C. Rinse the etched sample with a large amount of water first, then sprinkle it with alcohol, and after fully removing the water, use electricity to Blow dry with cool air;

...

Embodiment 3

[0057] (1) sodium metabisulfite and water are mixed with the aqueous solution A that is 1% concentration by mass percent;

[0058] (2) Picric acid and alcohol are configured into alcohol solution B with a mass percentage of 4% concentration;

[0059] (3) Prepare the etching solution: take 25ml of 1% aqueous solution A and 4% alcohol solution B respectively, mix them according to the volume ratio of 1:1, and add 0.2ml of concentrated hydrochloric acid with a concentration of 38%. well mixed.

[0060] (4) Put metallographic sample 5# (annealing temperature Ta=840°C) of dual-phase steel with a length of 20mm×width 15mm×thickness 1.5mm into the above-mentioned etching solution, the immersion time is 3s, and the immersion depth is 8- 15mm, take out the sample after the surface turns light blue, and control the etching temperature at 20-30°C. Rinse the etched sample with a large amount of water first, then sprinkle it with alcohol, and after fully removing the water, use electricit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com