Inclined shaft type plunger pump device

A plunger pump and oblique shaft technology, which is applied in the field of oblique axis plunger pump devices, can solve problems such as the inability to meet the needs of development, and achieve the effects of small friction loss, strong self-priming ability and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

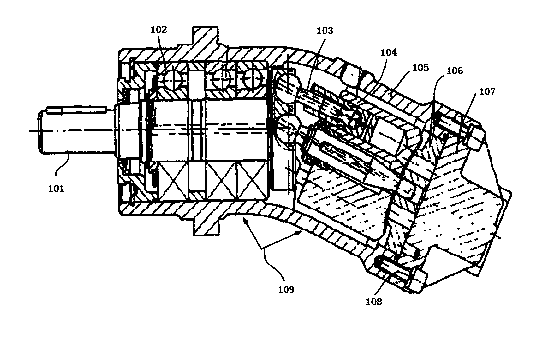

[0021] figure 1 A schematic structural view of an inclined-axis plunger pump device according to an embodiment of the present invention is shown. like figure 1 An inclined-axis plunger pump device shown includes a main shaft 101, a bearing 102, a connecting rod plunger pair 103, a cylinder block 104, a casing 105, a flow plate 106 and a rear cover 107, and one end of the rotating shaft 101 passes through the bearing 102 is connected to the inner wall of one end of the housing 105, the housing 105 is curved, one end of the rotating shaft 101 located in the housing 105 is connected to a connecting rod plunger pair 103, and the connecting rod plunger pair 103 is connected to the cylinder body 104 , the cylinder body 104 is connected with the valve plate 106, and the other end of the housing 105 is provided with a rear cover 107, through which the connecting rod plunger pair 103, the cylinder body 104 and the valve plate 106 are sealed in Inside the casing 105 .

[0022] The re...

Embodiment 2

[0029] The main shaft is supported on three bearings, one of which can also be a double angular contact ball bearing, which can withstand both large axial force and certain radial force. The other bearing is a deep groove ball bearing, which mainly bears radial force. The bearing set can ensure the stable high-speed rotation of the main shaft and has a long service life.

[0030] Disc springs can be set at the bearings (can be close to figure 1 The left bearing shown) is used to ensure the pretightening force of the paired double angular contact ball bearings, and at the same time, it can also make the bearings run normally with low noise when rotating at high speed.

[0031] The end cap can seal the gap between the end cap and the housing through an O-ring to prevent leakage. The connecting rod and plunger pair can be connected together by radial rolling of two parts, the connecting rod and the plunger. The large ball head of the connecting rod is pressed in the ball socke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com