Preparation method of polyester staple fiber used for vortex spinning

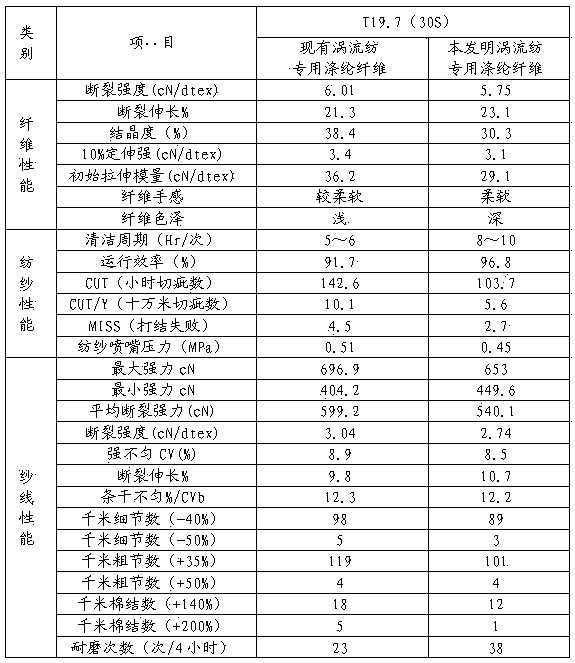

A polyester staple fiber, vortex spinning technology, applied in the direction of single-component copolyester rayon, etc., can solve the problems of poor molecular chain segment mobility, fluctuating diethylene glycol content, high nozzle air pressure, and achieve the failure rate of knotting Reduced, extended cleaning cycles, improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a method for preparing polyester staple fibers for vortex spinning. PTA and IPA are used as dibasic acids, EG is used as dibasic alcohols for esterification, and then DEG is added to polycondensate under catalyst catalysis to obtain copolyester. Then it is processed by polyester staple fiber spinning process to make polyester staple fiber for vortex spinning.

[0021] The preparation method of polyester staple fiber for vortex spinning of the present invention comprises the following steps:

[0022] In the esterification step, PTA, IPA, and EG are used as raw materials, and the esterification reaction is carried out at a temperature of 230-270 ° C and an absolute pressure of 0.1-0.3 MPa, and the esterification product is obtained after 1-5 hours of reaction;

[0023] In the polycondensation step, the esterification product is used as the raw material, and then DEG is added, under the catalysis of the catalyst, under the conditions of 240-285°C and...

Embodiment 1

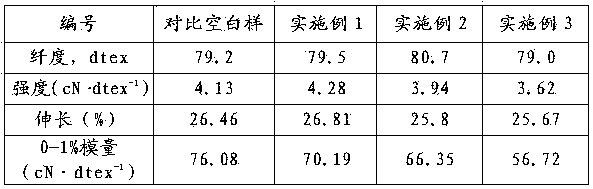

[0031] On the 300L polymerization device, add PTA, IPA and EG into the polymerization kettle, the molar ratio of acid to alcohol is 1:1.39, the amount of IPA added is 1% of PTA (mass ratio, the same below), and the direct esterification reaction is at 230~ It is carried out at 270°C, the absolute pressure of the esterification reaction is 0.1-0.3 MPa, the by-product water and the remaining EG are distilled off, and the esterification reaction is completed in 2-3 hours. Then, using ethylene glycol antimony as a catalyst, the dosage is 300*10 -6 g ethylene glycol antimony / g (PTA+IPA), then add DEG accounting for 0.2% of the total ingredients of PTA, IPA and EG, start vacuuming, and raise the temperature. The polycondensation reaction is carried out under the pressure, and the reaction is completed in 3 to 4 hours (the intrinsic viscosity of the copolyester melt is controlled within the range of 0.65±0.03dl / g, the same below), and the copolyester chips are obtained by pelletizing...

Embodiment 2

[0033] On the 300L polymerization device, PTA, IPA and EG are added to the polymerization kettle, the molar ratio of acid to alcohol is 1:1.39, the amount of IPA added is 2% of PTA, and the direct esterification reaction is carried out at 230-270°C. The absolute pressure of the reaction is 0.1-0.3 MPa, the by-product water and the remaining EG are distilled off, and the esterification reaction is completed in 2-3 hours. Then, using ethylene glycol antimony as a catalyst, the dosage is 300*10 -6 g ethylene glycol antimony / g (PTA+IPA), then add DEG accounting for 0.5% of the total ingredients of PTA, IPA and EG, start vacuuming, and raise the temperature. The polycondensation reaction was carried out under the following conditions, and the reaction was completed in 3 to 4 hours. After pelletizing and drying, copolyester chips were obtained. The conventional properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com