A kind of coal catalytic gasification reaction material and its preparation method and application

A technology for coal catalytic gasification and reaction material, which is applied to the application field of coal catalytic gasification reaction material in coal catalytic gasification, and can solve the problems of increasing catalyst loss, reducing the gasification activity of coarse-grained coal powder, and high catalyst loading. , to achieve the effect of improving gasification activity, reducing loss and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the coal catalytic gasification reaction material in the present invention is not limited. For example, it can be prepared by the preparation method described below in the present invention.

[0031] The present invention provides a method for preparing a reaction material for coal catalytic gasification, wherein the method includes: immersing and contacting a plurality of parts of coal powder with successively increasing particle diameters with a solution containing a coal catalytic gasification catalyst, and The conditions are such that, relative to the same mass unit of pulverized coal, the amount of coal catalytic gasification catalyst impregnated on the next part of the coal with a large particle size is not less than that of the adjacent previous part of the coal with a small particle size. The amount of coal catalytic gasification catalyst.

[0032] In the present invention, the multiple parts with increasing particle size means that the aver...

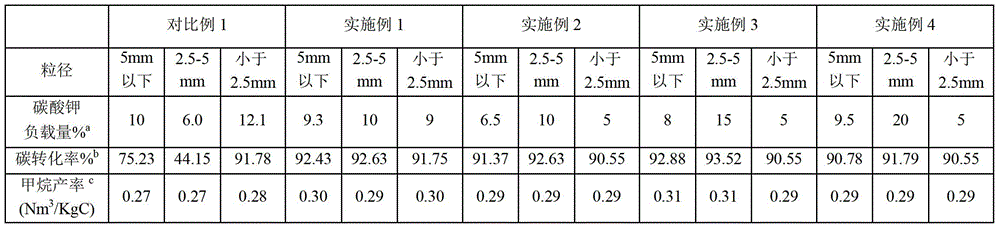

Embodiment 1

[0065] Choosing Buliangou bituminous coal (carbon content about 60% by mass) as the coal, crushed to a particle size range below 5mm (the upper limit of the particle size is 5mm, and the particle size distribution is in the range of 2.5-5mm (including the end value 2.5). mm and 5mm) pulverized coal accounted for 30% by mass, less than 2.5mm pulverized coal accounted for 70% by mass); divided into the first part of the particle size range of less than 2.5mm (average particle size 0.8mm), and the particle size range is The second part of 2.5-5mm (average particle size 3.4mm); then immerse and contact as follows:

[0066] Dissolve 3 g of potassium carbonate in 50 ml of deionized water, immerse and contact the obtained potassium carbonate solution with 30 g of a 2.5-5 mm second portion of coal powder, stir well and let stand for 1 hour to obtain a contacted mixture;

[0067] Dissolve 6.3 g of potassium carbonate in 50 ml of deionized water, immerse and contact 70 g of the first part of...

Embodiment 2

[0073] The non-liangou bituminous coal (carbon content is about 60% by mass) is selected as the coal, and it is crushed to a particle size range below 5mm (the upper limit of the particle size is 5mm, of which the pulverized coal with a particle size distribution in the range of 2.5-5mm accounts for 30 Mass%, coal powder less than 2.5mm accounted for 70% by mass); divided into the first part with a particle size range of less than 2.5mm (average particle size 0.8mm), and a particle size range of 2.5-5mm (including the end value 2.5mm And 5mm) the second part (average particle size 3.4mm); then immerse contact as follows:

[0074] Dissolve 3 g of potassium carbonate in 50 ml of deionized water, immerse and contact the obtained potassium carbonate solution with 30 g of a 2.5-5 mm second portion of coal powder, stir well and let stand for 1 hour to obtain a contacted mixture;

[0075] Dissolve 3.75g of potassium carbonate in 50ml of deionized water, immerse and contact 70g of the firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com