Natural mineral-based catalyst and gasification method using the same

A technology of natural minerals and catalysts, applied in the field of fluidized bed gasification, to achieve the effect of easy separation and recovery, and improved gasification activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

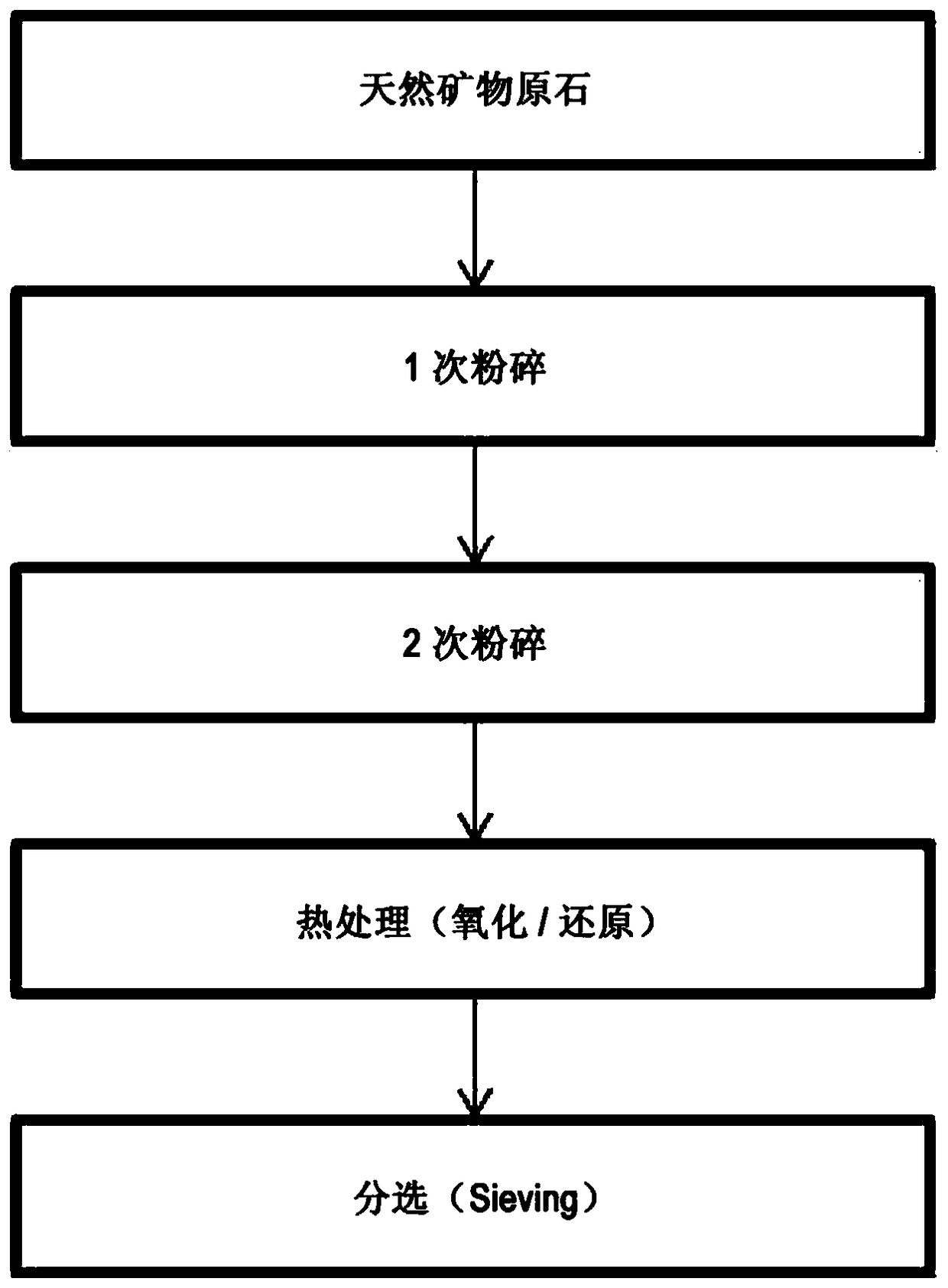

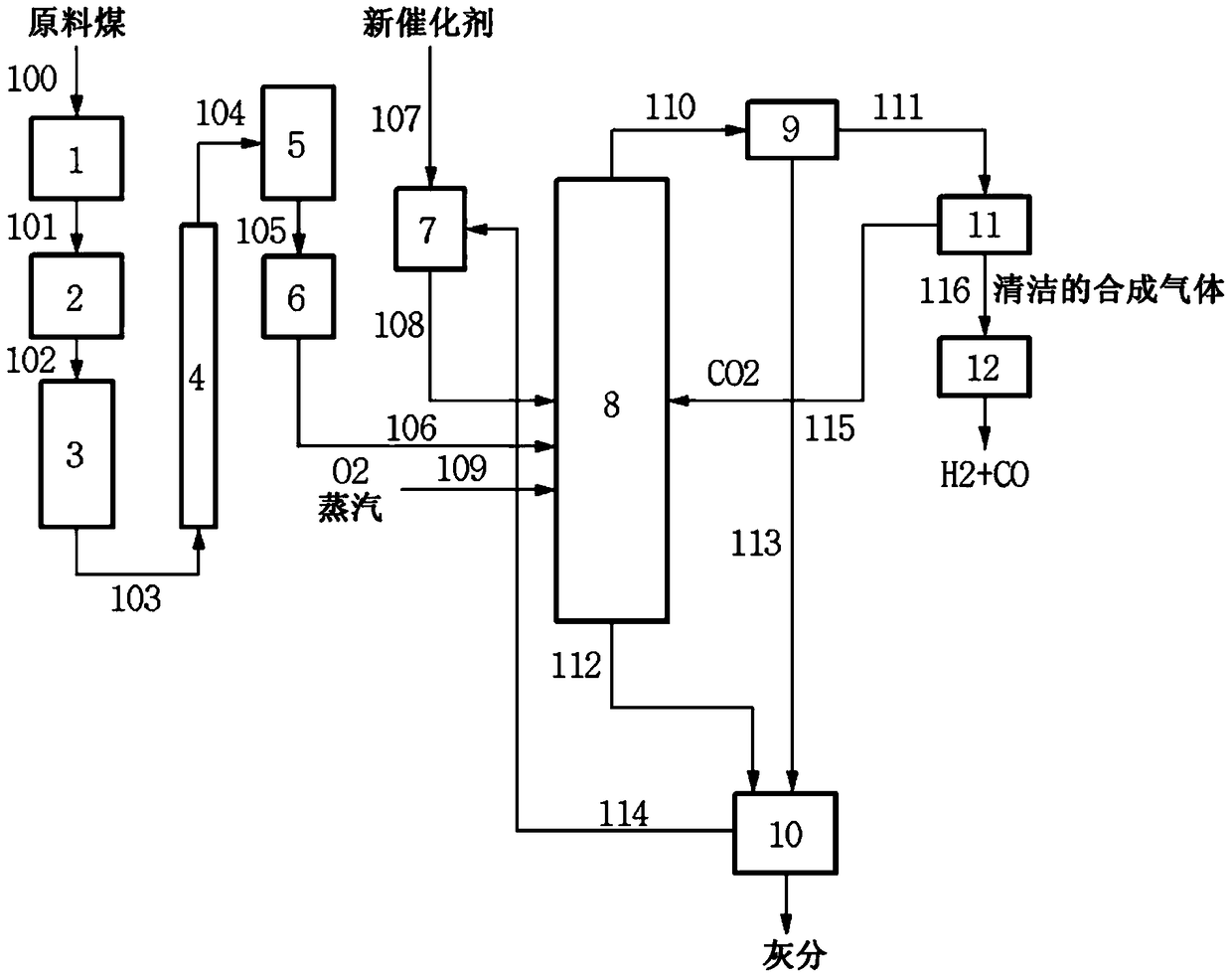

Method used

Image

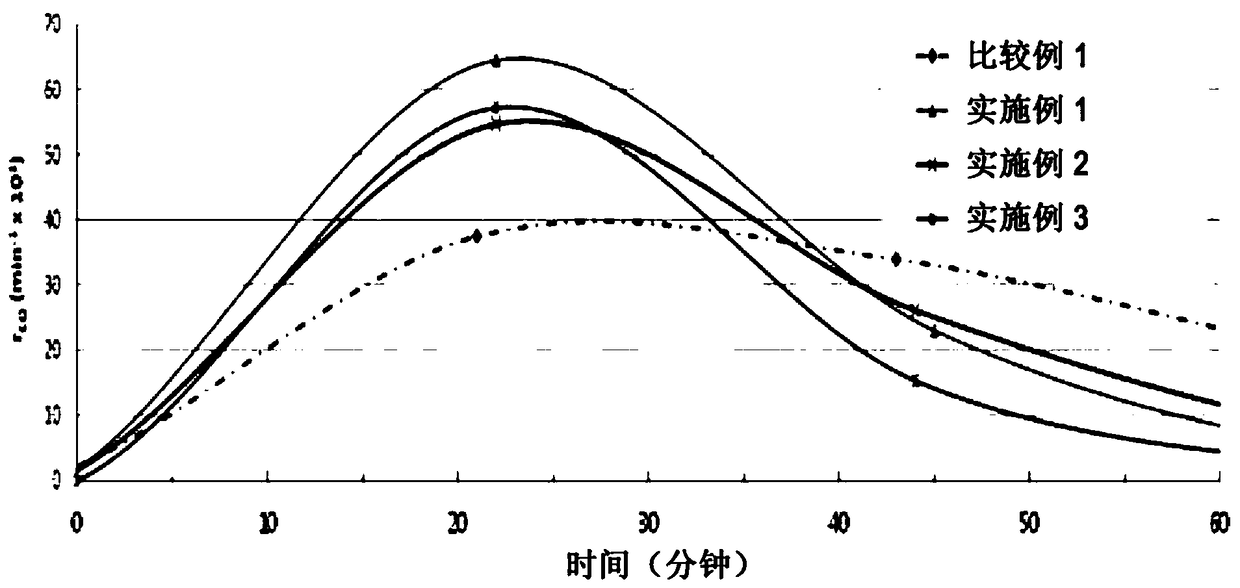

Examples

Embodiment 1

[0131] Manufacture of catalyst using natural zeolite (1)

[0132] As an aqueous Fe precursor solution, FeCl 2 4H 2 Fe of O (Sanden Pure Chemical Industries, Ltd. Iron (II) chloride tetrahydrate, 99%), and as the Mg precursor aqueous solution, prepared MgCl 2 ·6H 2 Mg of O (Magnesium chloride hexahydrate from Sanden Junyaku Co., Ltd., 98%).

[0133] Thereafter, as described above, 100 g of natural zeolite particles heat-treated at 350° C. were put into a 1-liter beaker, and then 125 g of the Fe precursor aqueous solution and 94 g of the Mg precursor aqueous solution were added thereto. The mixture was stirred at 75°C for 6 hours, filtered, and the filtrate was dried at 105°C, and then calcined in an air atmosphere at a temperature of 900°C to produce a gasification catalyst.

[0134] The composition of the catalyst was analyzed by ICP-OES (720ICP-OES from Agilent Technologies), and it was confirmed that it contained 20.5% by weight of MgO and 27.0% by weight of Fe 2 o 3...

Embodiment 2

[0136] Production of catalysts using dolomite

[0137] As an aqueous Fe precursor solution, FeCl 2 4H 2 Fe of O (Sanden Pure Chemical Industries, Ltd. Iron (II) chloride tetrahydrate, 99%), and KCl K (Sanden Pure Chemical Industries, Ltd. Potassium chloride, 99.5%).

[0138] Thereafter, 100 g of the calcined dolomite particles were put into a 1 L beaker, and then 125 g of the Fe precursor aqueous solution and 74 g of the K precursor aqueous solution were added thereto. The above-mentioned mixture was stirred at 75°C for 6 hours, filtered, and the obtained solid was dried at 105°C, and then calcined in an air atmosphere at a temperature of 950°C to produce a catalyst.

[0139] The composition of the catalyst was analyzed by ICP-OES (720ICP-OES from Agilent Technologies), and it was confirmed that it contained 24.0% by weight of MgO and 27.5% by weight of Fe 2 o 3 and 10.5% by weight of K 2 O.

Embodiment 3

[0141] Production of catalysts using eluate of natural zeolite and olivine

[0142] 100 g of the above-produced olivine particles were put into a 1 L beaker, 400 ml of 5N hydrochloric acid was added thereto, stirred at 90° C. for 3 hours, and the acid-treated mixture was filtered to separate and recover the eluate.

[0143] The contents of elements (ions) extracted from the recovered eluate sample (5 ml) are shown in Table 7 below.

[0144] 【Table 7】

[0145] element (ion)

Mg

Ca

Fe

Al

Si

Content (wt%)

0.60

0.01

0.21

0.03

0.51

[0146] 100 g of the natural zeolite particles produced above were put into a 1 L beaker, and then 200 ml of the eluate was added. Thereafter, the mixture was stirred at 75° C. for 6 hours, filtered, and the obtained solid matter was dried at 105° C., and then calcined in an air atmosphere at a temperature of 900° C. to produce a catalyst.

[0147] The composition of the catalyst was analyzed by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com