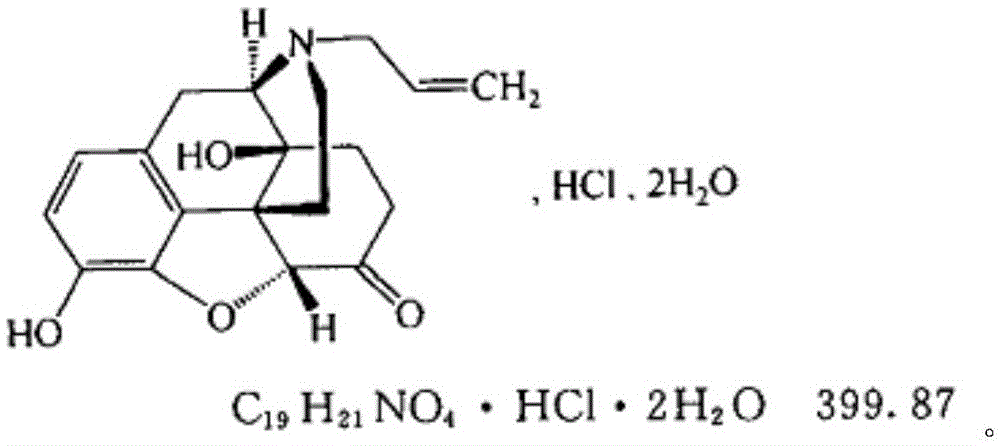

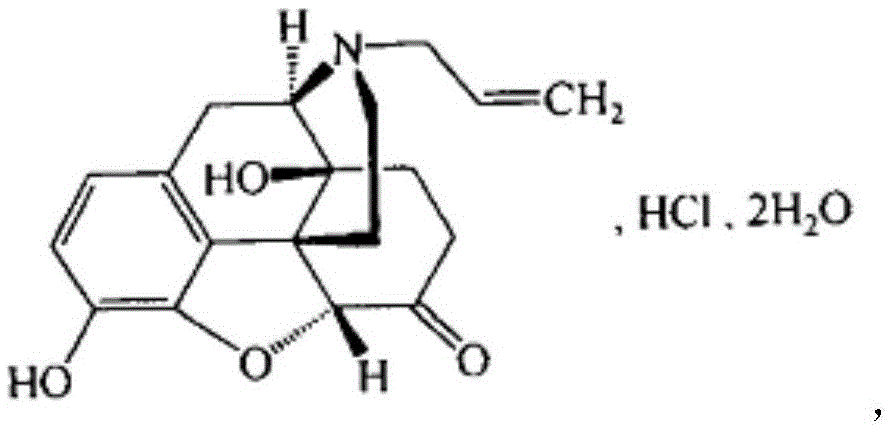

The synthetic method of naloxone hydrochloride

A technology of naloxone hydrochloride and its compound, which is applied in the field of medicine, can solve problems such as low yield, great harm to synthetic workers, and environmental pollution, and achieve the effects of low impurity content, increased reaction speed, and excellent product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

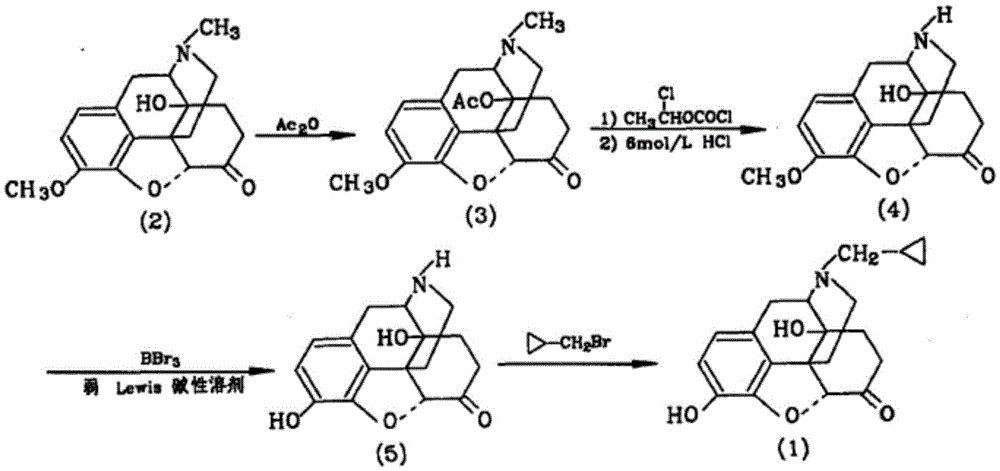

Method used

Image

Examples

Embodiment 1

[0071] Embodiment 1: Preparation of naloxone hydrochloride in dihydrate form

[0072] Step 1: Dissolve 10g of thebaine in 100ml of formic acid, keep warm at 20°C, stir and add 33g of m-chloroperoxybenzoic acid dropwise, after keeping warm for 5 hours, replace the system with nitrogen 4 times, add 0.5g of Raney nickel, and replace with hydrogen for 4 Once the system is stable, keep warm at 30°C, hydrogenate for 10 hours, filter, filter the cake (the filter cake is the catalyst), wash twice with 10ml of water, adjust the pH of the filtrate to 8-9 with 30% sodium hydroxide solution, filter, and vacuum the filter cake Dry to obtain compound 2, 8.12g;

[0073] Step 2: Add 8.12g of the compound obtained in the previous step into a reaction flask, add 82ml of acetic anhydride, heat up to 70°C, and react for 1 hour, then concentrate the system to dryness in vacuo to obtain Compound 3, 8.91g;

[0074] Step 3: Put 8.91g of the compound obtained in the previous step into the reaction f...

Embodiment 2

[0079] Embodiment 2: Preparation of naloxone hydrochloride in dihydrate form

[0080] Step 1: Dissolve 10g of thebaine in 110ml of formic acid, keep warm at 25°C, stir and add 35.2g of m-chloroperoxybenzoic acid dropwise, after keeping warm for 3 hours, replace the system with nitrogen for 5 times, add 0.6g of Raney nickel, and replace with hydrogen 4 times, wait for the system to be stable, keep warm at 25°C, hydrogenate for 12 hours, filter, filter cake (the filter cake is the catalyst), wash 2 times with 10ml water, adjust the pH of the filtrate to 8-9 with 30% sodium hydroxide solution, filter, and filter the cake Vacuum drying to obtain compound 2, 8.31g;

[0081] Step 2: Add 8.31 g of the compound obtained in the previous step into a reaction flask, add 84 ml of acetic anhydride, raise the temperature to 60°C, and react for 1 hour, then concentrate the system to dryness in vacuo to obtain Compound 3, 8.78 g;

[0082] Step 3: Put 8.78g of the compound obtained in the p...

Embodiment 3

[0087] Embodiment 3: Preparation of naloxone hydrochloride in dihydrate form

[0088] Step 1: Dissolve 10g of thebaine in 130ml of formic acid, keep warm at 20°C, add 30g of m-chloroperoxybenzoic acid dropwise, keep warm for 7 hours, replace the system with nitrogen for 3 times, add 0.5g of Raney nickel, and replace with hydrogen for 5 times , when the system is stable, keep warm at 30°C, hydrogenate for 10 hours, filter, filter the cake (the filter cake is the catalyst), wash twice with 10ml of water, adjust the filtrate to PH=8-9 with 30% sodium hydroxide solution, filter, and dry the filter cake in vacuum Dry to obtain compound 2, 8.05g;

[0089] Step 2: Add 8.05 g of the compound obtained in the previous step into a reaction flask, add 92 ml of acetic anhydride, heat up to 80°C, and react for 1 hour, then concentrate the system to dryness in vacuo to obtain Compound 3, 8.73 g;

[0090] Step 3: Put 8.73g of the compound obtained in the previous step into a reaction flask...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com