Method and device for producing alpha-type gypsum in large scale with low cost

A large-scale, low-cost technology, applied in the field of large-scale production of α-type gypsum, low-cost, can solve the problems of limited application of α-type gypsum, inability to large-scale production, complex preparation process, etc., to save site space and management personnel costs , the effect of short time consumption and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

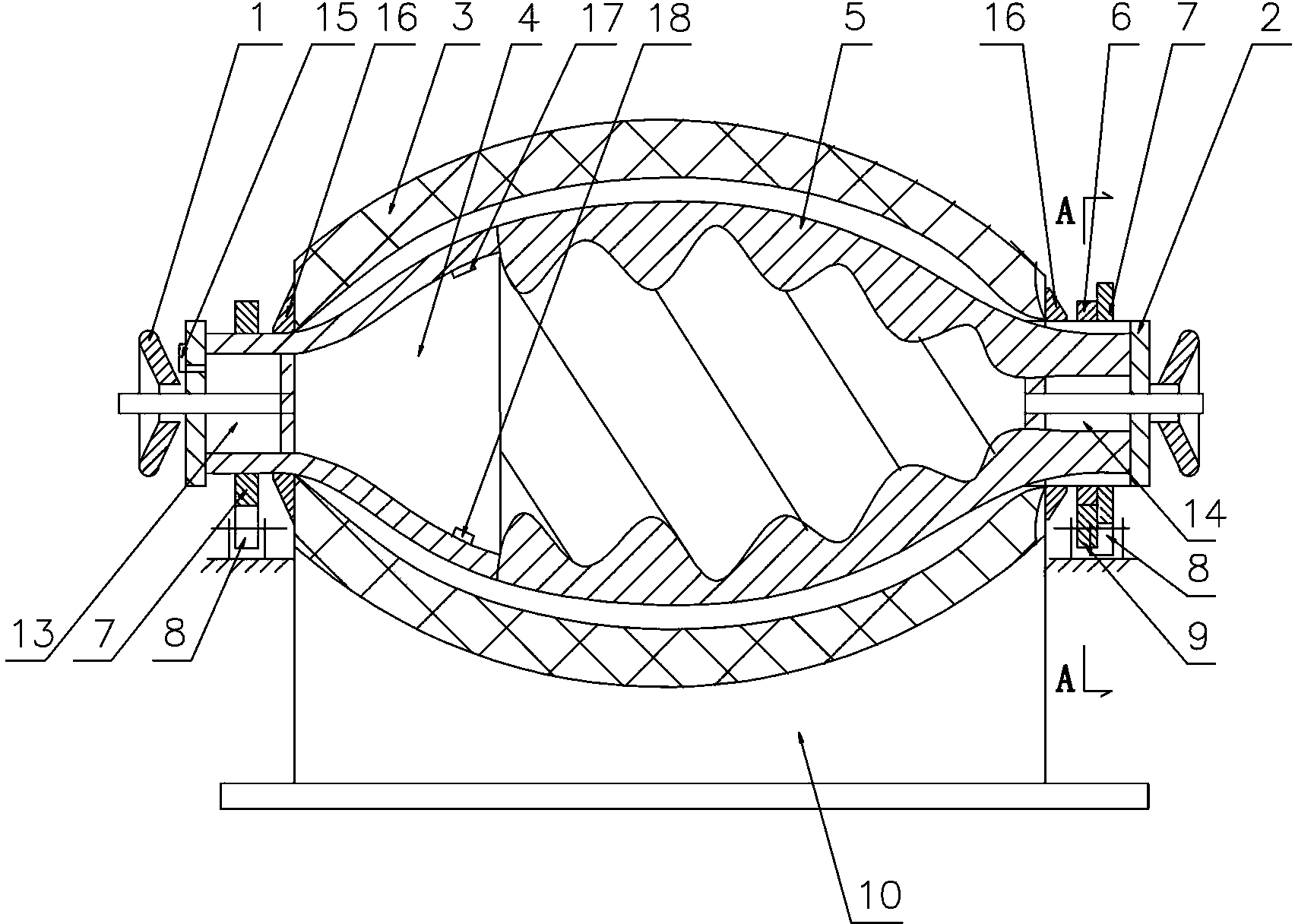

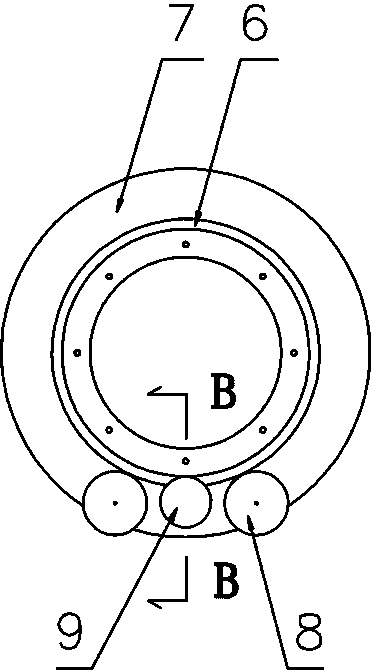

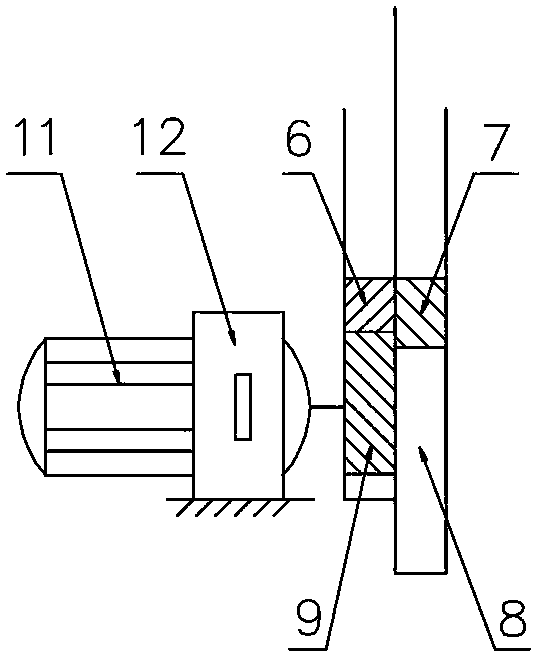

[0028] see figure 1 , a kind of low-cost of present embodiment, the method for large-scale production of α-type gypsum, carries out according to the following steps:

[0029] (1) Select gypsum powder containing 15% of attached water, 19% of crystal water, and 93% of calcium sulfate dihydrate grade, spray 5% of the total mass of gypsum powder with water, and use a granulator to make 8-10mm dihydrate gypsum balls regiment, spare;

[0030] (2) Open the feed door 13 of the special rotary calcining kiln for α-type gypsum, start the drive motor 11 to reverse the rotation of the rotary kiln body 4 at a speed of 7r / min, and at the same time turn on the switch for heating the electric furnace body 3 to set the heating of the electric furnace body The temperature is 900°C. When the temperature of the rotary kiln body rises to 450-550°C, add the dihydrate gypsum pellets prepared in step (1) into the rotary kiln body. The amount of feed is 30% of the total volume of the rotary kiln body....

Embodiment 2

[0036] A kind of low-cost of the present invention, the method for large-scale production α-type gypsum, carry out according to the following steps:

[0037] (1) Select gypsum powder containing 10% of attached water, 20% of crystal water, and 90% of calcium sulfate dihydrate grade, spray water with 7% of the total mass of gypsum powder, and use a granulator to make 5-8mm dihydrate gypsum pellets, spare;

[0038] (2) Open the feed door of the α-type gypsum rotary kiln, start the motor to reverse the rotary kiln body, and at the same time turn on the switch for heating the electric furnace body, set the heating temperature of the electric furnace body to 800°C, and wait for the temperature of the rotary kiln body to rise When the temperature reaches 450-550°C, add the dihydrate gypsum pellets prepared in step (1) into the rotary kiln body, and the feeding amount is 40% of the total volume of the rotary kiln body. After the feeding is completed, close and seal the feeding door ;...

Embodiment 3

[0042] A kind of low-cost of the present invention, the method for large-scale production α-type gypsum, carry out according to the following steps:

[0043] (1) Select gypsum powder containing 13% of attached water, 15% of crystal water, and 95% of calcium sulfate dihydrate grade, spray 6% of the total mass of gypsum powder into water, and use a granulator to make 5-8mm dihydrate gypsum pellets, spare;

[0044] (2) Open the feed door of the α-type gypsum-specific direct-heating self-generating steam-type rotary calcination kiln, start the motor to reverse the rotary kiln body, and at the same time turn on the switch for heating the electric furnace body, and set the heating temperature of the electric furnace body to 1000°C. When the temperature of the rotary kiln body rises to 450-550°C, add the dihydrate gypsum pellets prepared in step (1) into the rotary kiln body. The amount of feed is 35% of the total volume of the rotary kiln body. And seal the feed door;

[0045] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com