Sorting type waste transfer station

A garbage transfer station and garbage technology, applied in the field of sanitation, can solve the problems of easy odor, waste, inconvenient garbage transfer, etc., and achieve the effect of wide application range, simple structure and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

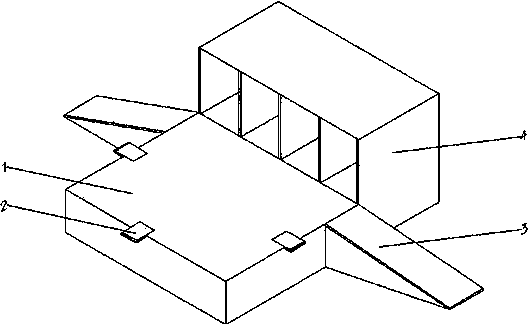

[0043] Embodiment one, such as figure 1 As shown, the classified transfer garbage transfer station provided by the present invention includes a loading and unloading platform 1, an inclined transportation channel 3, a garbage storage room 4, a garbage transfer box, a loading and unloading plate 2 and a reversing reference line 13; the loading and unloading platform 1 is a raised structure, its height is equal to the height of the body of the transfer vehicle, and the loading and unloading platform 1 is provided with at least one inclined transportation channel 3, and the inclined transportation channel 3 is used as a cleaner to transport the garbage to the loading and unloading platform 1 by rickshaw, which is convenient Loading garbage bins; the loading and unloading platform 1 is provided with at least one loading and unloading plate 2, which is used to unload the garbage cans from the transfer vehicle or load the garbage bins from the loading and unloading platform 1 to the ...

Embodiment 2

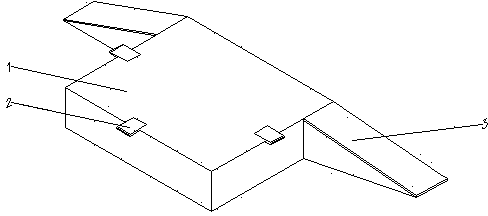

[0061] Embodiment two, such as Figure 4 and Figure 7 As shown, adopt the classification transshipment garbage transfer station with the embodiment one, the structure of the classification transshipment garbage transfer station of the structure of the present invention is built in the building, with one or two rooms on the first floor as the garbage storage room 4, and by setting and The outlet connected to the loading and unloading platform 1 is used to transfer garbage and load and unload furniture through the provided loading and unloading platform 1 .

[0062] Adopt the classified transshipment garbage transfer station provided by Embodiment 2 of the present invention, first build the transfer station on a ground of the building, use one or two rooms on the first floor as the garbage storage room 4, and link to each other by setting the loading and unloading platform 1 Export, all the other specific operation schemes are as embodiment one.

[0063] In addition, compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com