Medicinal symmetrical cold-forming aluminum-casting plate

A cold forming and symmetrical technology, applied in the direction of layered products, metal layered products, chemical instruments and methods, etc., can solve the problems of poor adaptability, residue, waste of electric energy, etc., achieve good ductility and mechanical properties, and reduce costs and delivery cycle, and the effect of reducing waste emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with each specific embodiment and accompanying drawing, the present invention will be further described:

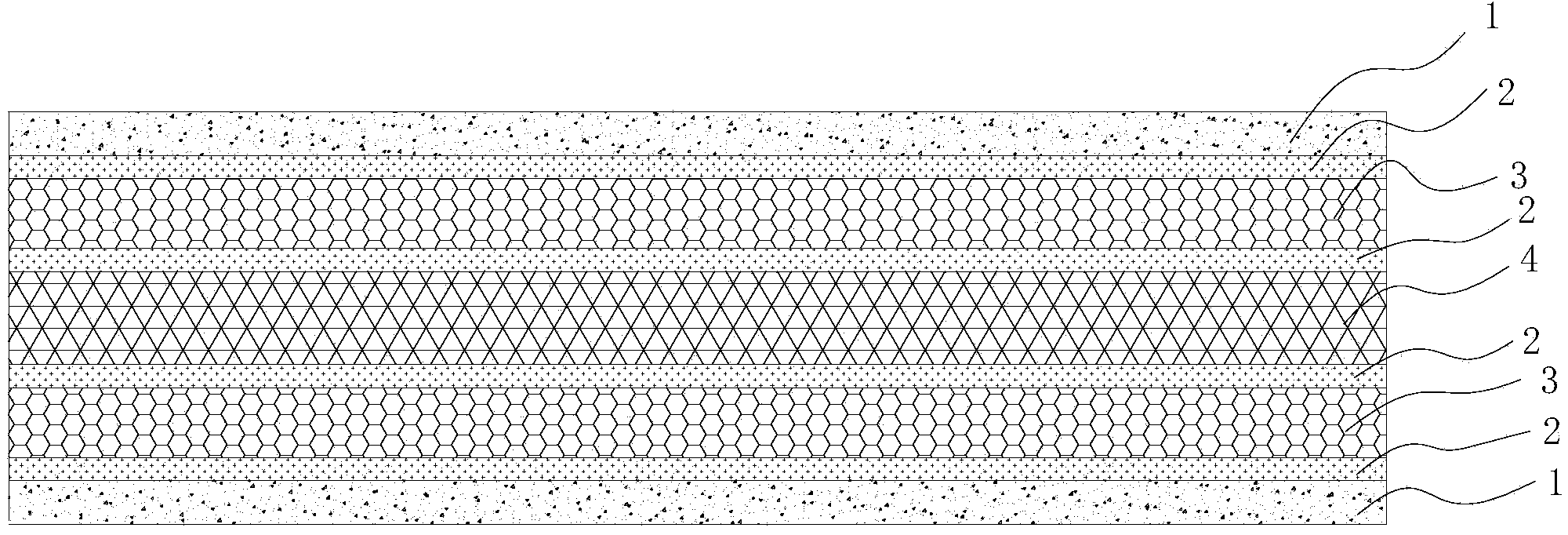

[0015] See figure 1 As shown, the medical symmetrical cold-formed aluminum cast hard sheet has a layered structure, and it is composed of an aluminum base layer 4 with a thickness of 40-60 microns in the middle, which is close to the 4-8 microns on the upper and lower sides of the aluminum base layer 4. The thickness of the new functional adhesive resin (AD) 2, the upper layer of the new adhesive resin (AD) 2 on the upper side is provided with 10-15 micron thickness nylon (PA) 3, 4-8 micron outside the nylon (PA) 3 The thickness of the new functional adhesive resin (AD) 2, the outer layer of the new adhesive resin (AD) 2 is provided with a homogeneous polypropylene layer (PP) 1 with a thickness of 8-12 microns; Nylon (PA) 3 with a thickness of 10-15 microns on the lower side of the new adhesive resin (AD) 2, and a new functional adhesive resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com