Thermosetting polymer matrix composite resistance welding device and method

A composite material and resistance welding technology, which is applied in the field of thermosetting polymer-based composite material resistance welding devices, can solve the problems that the fusion connection technology cannot be applied to thermosetting polymer-based composite materials, current leakage, etc., to improve edge effects and current leakage, Reduced edge effects and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

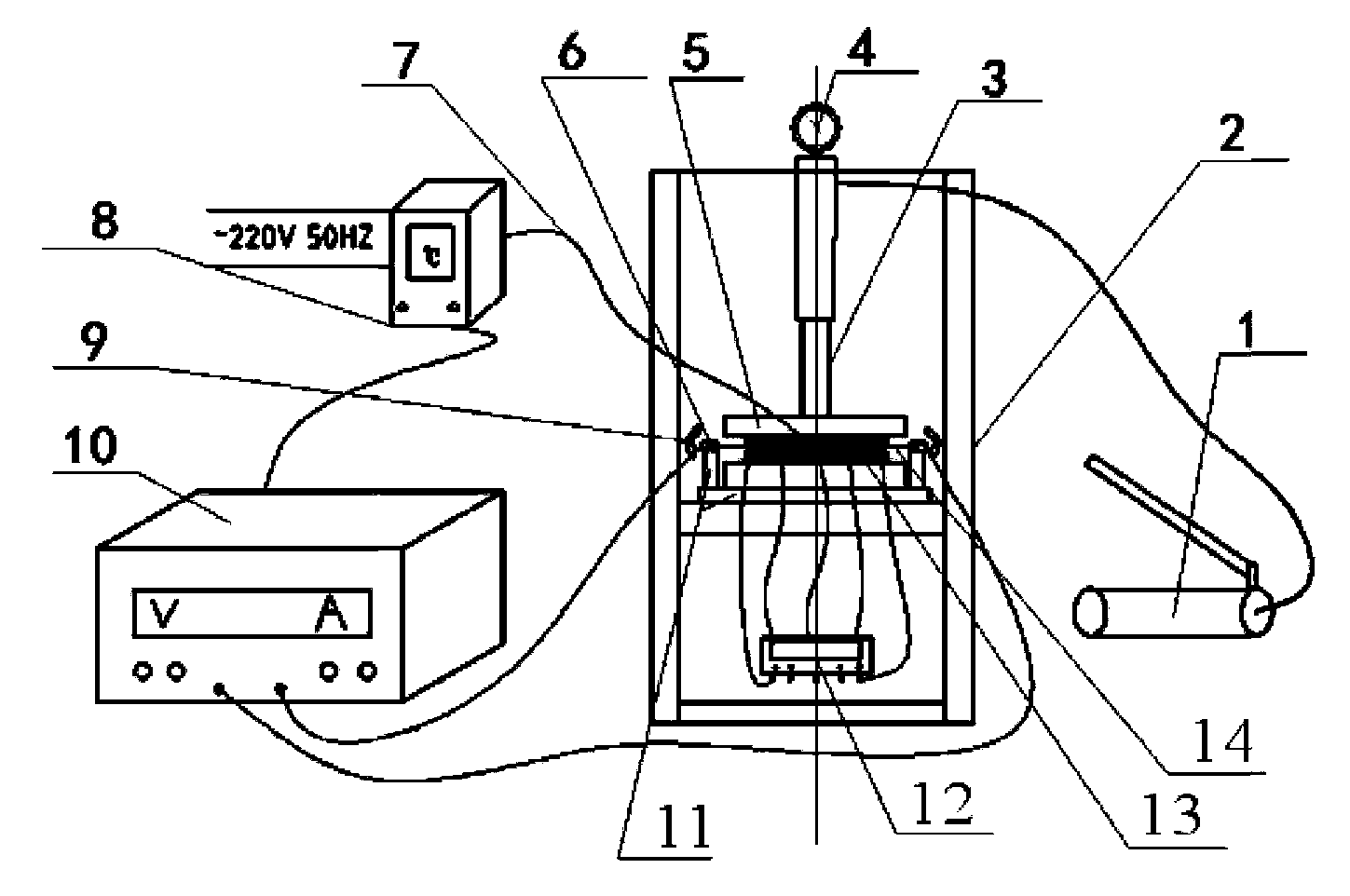

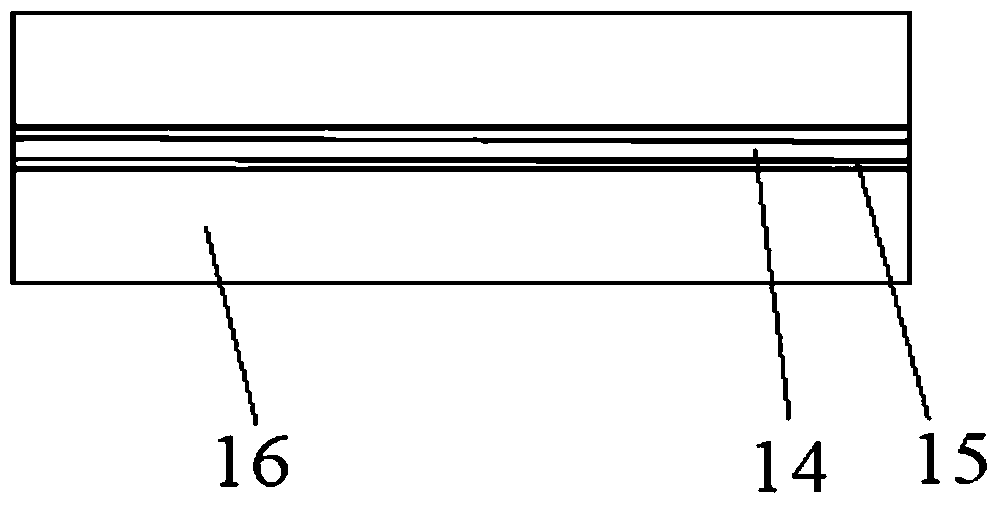

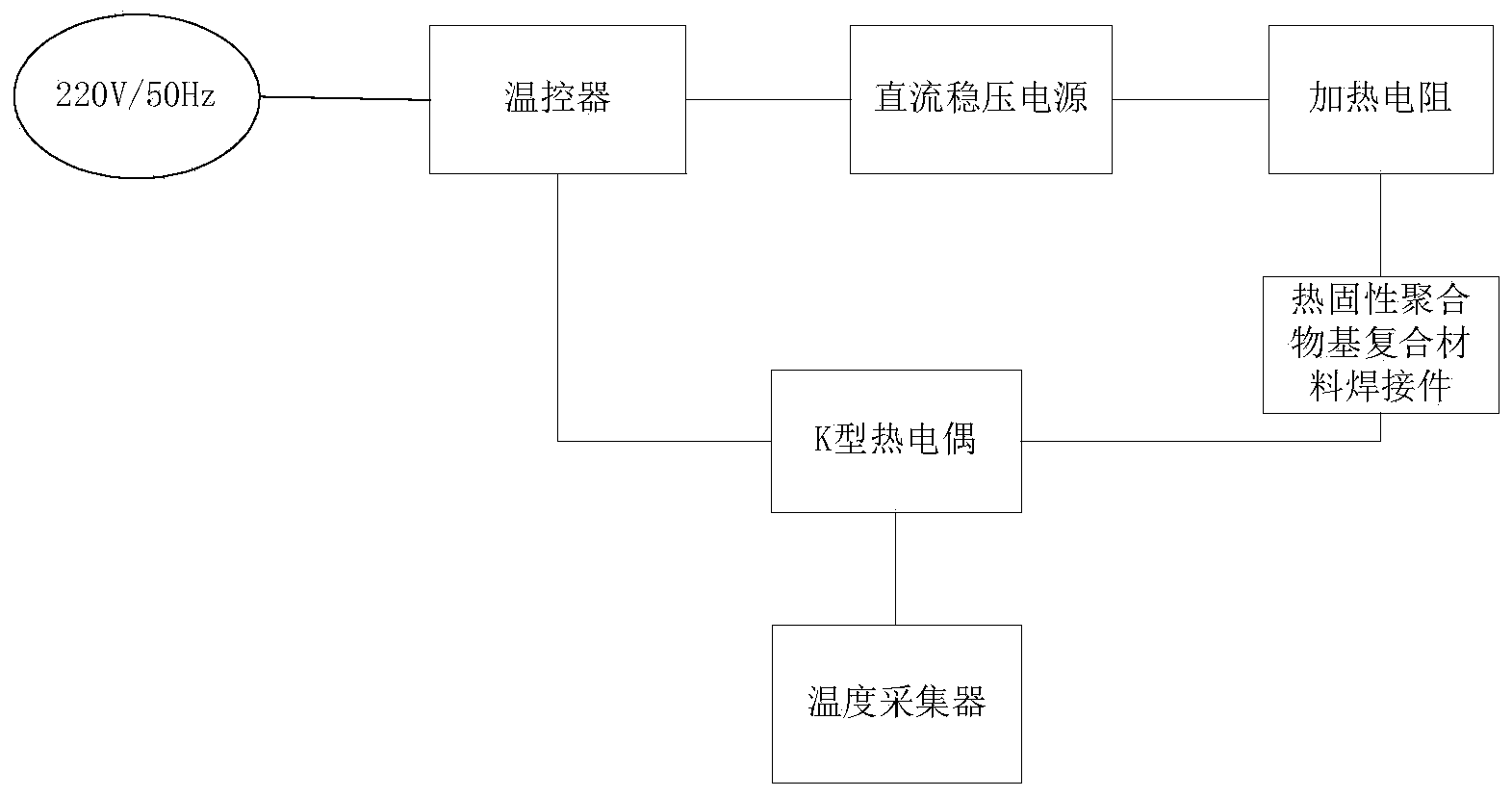

[0028] see figure 1 , the thermosetting polymer-based composite material resistance welding device of the present invention includes a housing 2 and a heating resistor 14 arranged in the housing 2, an insulating and heat-insulating jig 5 for placing the heating resistor 14, and an insulating and heat-insulating fixture 5 for placing the thermosetting polymer-based composite material. A pressurizing device that applies a pressure of 0.4 to 1.0 MPa to the welded part 13. The pressurizing device adopts the piston rod head 3 connected to the manual hydraulic pump 1. A pressure gauge is provided on the top of the piston rod head 3. Both sides of the heating resistor 14 are covered with a layer of thickness It is a thermoplastic film of 50-100 μm; the heating resistor 14 adopts unidirectional and / or woven carbon fiber cloth, and the two sides of the heating resistor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com