Real-time online detection and compensation device for thermal elongation deformation error of boring spindles of numerical control machine tool

A deformation error, CNC machine tool technology, used in measuring/indicating equipment, metal processing machinery parts, other manufacturing equipment/tools, etc. and application range, etc., to achieve good economic and social benefits, and the effect of reducing processing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

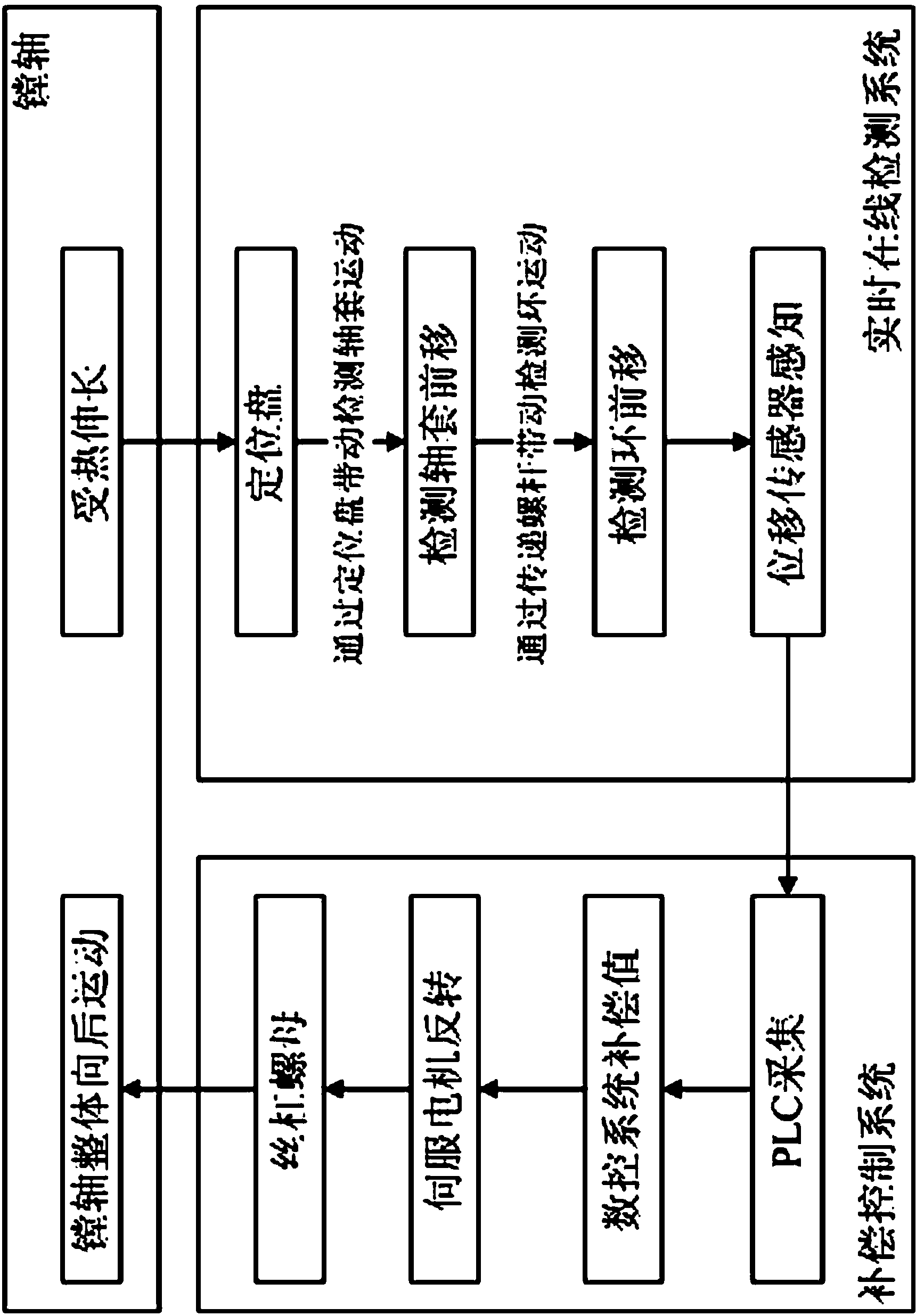

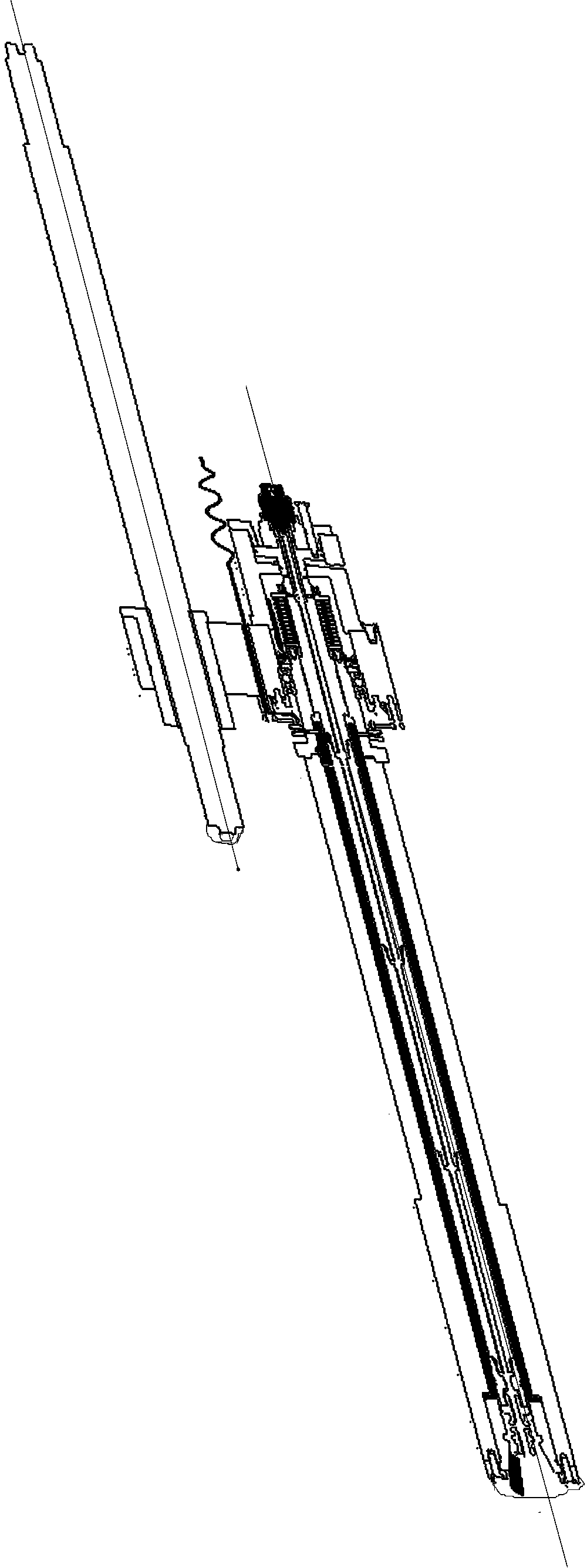

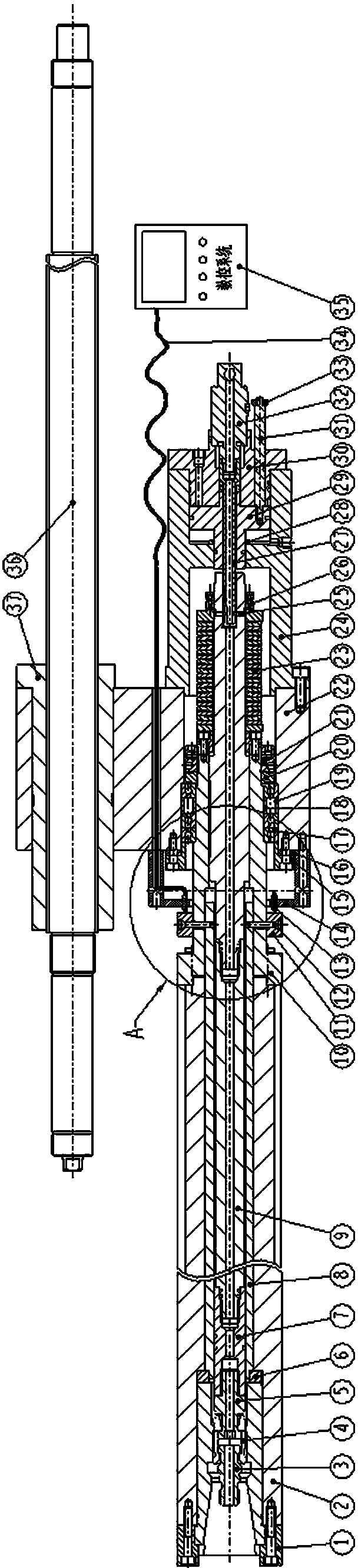

[0021] Such as figure 1 As shown, this kind of mechanical device used to reduce the influence of thermal elongation and deformation of the boring shaft of CNC machine tools mainly includes two parts: real-time on-line detection system and compensation control system. It mainly includes the positioning plate, the detection sleeve whose front end is fixedly connected with the front end of the boring shaft through the positioning plate, the detection ring, the transmission screw, the displacement sensor, the sensor mounting seat, the PLC analog input module, the temperature compensation function module of the numerical control system and the ball screw pair .

[0022] Working principle: In order to realize the real-time online detection function of the thermal elongation and deformation error of the above-mentioned boring shaft, the positioning plate, detection bushing, transfer screw, detection ring, sensor and its installation device are specially designed, and the thermal elon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com