Modified nanoscale zero-valent iron and preparing method thereof

A nano-zero-valent iron modification technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problem of affecting the reactivity and processing efficiency of nano-zero-valent iron, the instability of nano-zero-valent iron, reactivity, Reduced mobility and other issues, to achieve the effect of fast preparation, easy access, and low requirements for experimental equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

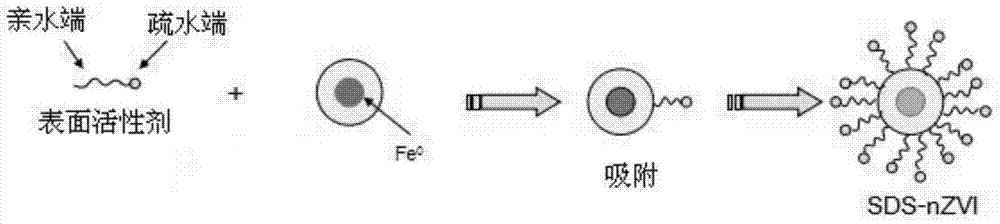

[0031] see figure 1 : a modified nano zero valent iron of the present invention, the modified nano zero valent iron comprises nano zero valent iron and sodium lauryl sulfate, and sodium lauryl sulfate wraps on the surface of nano zero valent iron to form a shell core The structure is that sodium dodecyl sulfate physically modifies the surface of nano zero-valent iron; the mass ratio of sodium dodecyl sulfate to nano zero-valent iron in the modified nano zero-valent iron is 0.01:1.

[0032] A preparation method of the above-mentioned modified nanometer zero-valent iron, comprising the following steps:

[0033] (1) FeSO 4 Solution preparation: weigh 0.7000g FeSO 4 ·7H 2 Put O in a beaker, add an appropriate amount of ultrapure water to dissolve and transfer to a 50mL volumetric flask, set the volume to the mark, and shake well to obtain 0.05M FeSO 4 solution.

[0034] (2)NaBH 4 Solution preparation: weigh 0.3783g NaBH 4 Put it in a beaker, add an appropriate amount of ult...

Embodiment 2

[0039] A modified nano-zero-valent iron of the present invention, the modified nano-zero-valent iron includes nano-zero-valent iron and sodium dodecyl sulfate, and the sodium dodecyl sulfate is wrapped on the surface of the nano-zero-valent iron to form a core-shell structure Carrying out physical modification on the surface of nanometer zero-valent iron; the mass ratio of sodium dodecyl sulfate to nanometer zero-valent iron in the modified nanometer zero-valent iron is 0.03:1.

[0040] A preparation method of the above-mentioned modified nanometer zero-valent iron, comprising the following steps:

[0041] (1) FeSO 4 Solution preparation: weigh 1.4000g FeSO 4 ·7H 2 Put O in a beaker, add an appropriate amount of ultrapure water to dissolve and transfer to a 50mL volumetric flask, set the volume to the mark, and shake well to obtain 0.1M FeSO 4 solution.

[0042](2)NaBH 4 Solution preparation: weigh 0.7566g NaBH 4 Put it in a beaker, add an appropriate amount of ultrapure...

Embodiment 3

[0047] A modified nano-zero-valent iron of the present invention, the modified nano-zero-valent iron includes nano-zero-valent iron and sodium dodecyl sulfate, and the sodium dodecyl sulfate is wrapped on the surface of the nano-zero-valent iron to form a core-shell structure and performing physical modification on the surface of the nanometer zero-valent iron; the mass ratio of sodium dodecyl sulfate to the nanometer zero-valent iron in the modified nanometer zero-valent iron is 0.05:1.

[0048] A preparation method of the above-mentioned modified nanometer zero-valent iron, comprising the following steps:

[0049] (1) FeSO 4 Solution preparation: weigh 3.9200g FeSO 4 ·7H 2 Put O in a beaker, add an appropriate amount of ultrapure water to dissolve, transfer the above solution to a 200mL volumetric flask, set the volume to the mark, and shake well to obtain 0.07M FeSO 4 solution.

[0050] (2)NaBH 4 Solution preparation: weigh 2.1437g NaBH 4 Put it in a beaker, add an ap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com